×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

498 Brake Calipers found

Audi Caliper Part Number: 1EA-615-123-B

$256.87 MSRP: $359.76You Save: $102.89 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Audi Caliper Part Number: 3Q0-615-424

$177.42 MSRP: $248.49You Save: $71.07 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Audi Caliper Part Number: 3Q0-615-423

$192.41 MSRP: $269.49You Save: $77.08 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Audi Caliper Part Number: 1EA-615-124-B

$179.92 MSRP: $251.99You Save: $72.07 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Audi Caliper Part Number: 8W0-615-124

$188.02 MSRP: $263.33You Save: $75.31 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Audi Caliper Part Number: 3C0-615-123

$236.14 MSRP: $330.74You Save: $94.60 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Audi Caliper Part Number: 1J0-615-423

$180.88 MSRP: $253.33You Save: $72.45 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

- Replaces: 8N0-615-423

Audi Caliper Part Number: 1J0-615-424

$180.88 MSRP: $253.33You Save: $72.45 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

- Replaces: 8N0-615-424

Audi Caliper Part Number: 3C0-615-124

$249.89 MSRP: $349.99You Save: $100.10 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Audi Caliper Part Number: 4F0-615-123

$177.89 MSRP: $249.16You Save: $71.27 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Audi Caliper Part Number: 5G0-615-424-B

$278.01 MSRP: $389.36You Save: $111.35 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Audi Caliper Part Number: 5Q0-615-423-G-QC8

$183.66 MSRP: $257.24You Save: $73.58 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Housing; Caliper

- Position: Left

Audi Caliper Part Number: 1K0-615-124-E

$293.62 MSRP: $411.24You Save: $117.62 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

- Replaces: 1K0-615-124-EX, 1K0-615-124-B

Audi Caliper Part Number: 5N0-615-123

$293.62 MSRP: $411.24You Save: $117.62 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Audi Caliper Part Number: 5N0-615-124

$293.62 MSRP: $411.24You Save: $117.62 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Audi Caliper Part Number: 3Q0-615-423-E-SL7

$296.75 MSRP: $415.61You Save: $118.86 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Housing; Caliper

- Position: Left

Audi Caliper Part Number: 3Q0-615-423-F-SL7

$296.75 MSRP: $415.61You Save: $118.86 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Housing; Caliper

- Position: Left

Audi Caliper Part Number: 3Q0-615-424-E-SL7

$296.75 MSRP: $415.61You Save: $118.86 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Housing; Caliper

- Position: Right

Audi Caliper Part Number: 3Q0-615-424-F-SL7

$296.75 MSRP: $415.61You Save: $118.86 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Housing; Caliper

- Position: Right

Audi Caliper Part Number: 8E0-615-423-G

$260.24 MSRP: $364.49You Save: $104.25 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

- Replaces: 8E0-615-423-B

| Page 1 of 25 |Next >

1-20 of 498 Results

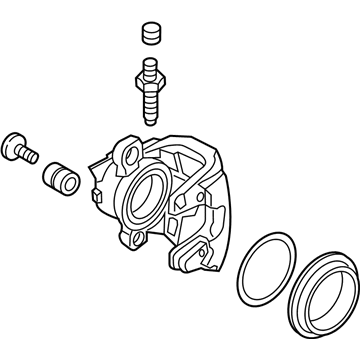

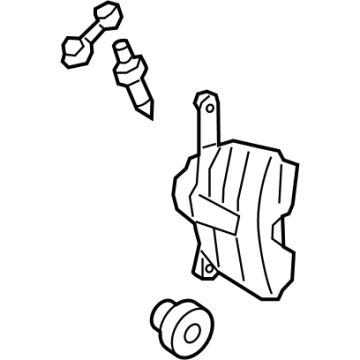

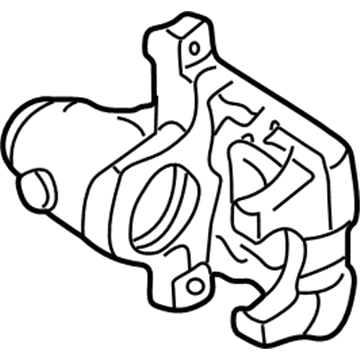

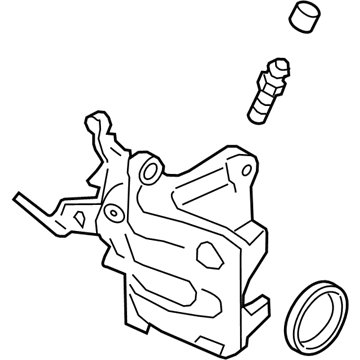

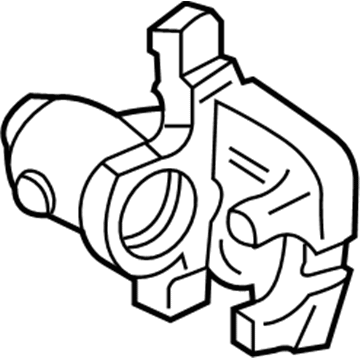

Audi Brake Caliper

It's needless to say, the Audi brake caliper is one of the most important part of the disc brake system. In some cars, it is found in the front, while in others, it is at the rear. The brake fluid flows into the caliper when you drive your car and depress the brake pedal. Consequently, this fluid causes pressure against the piston inside, which makes contact with the rotor to stop your vehicle. Nevertheless, with time and heat effects, brake calipers start becoming rusty, thereby leaking brake fluid from them. If you see any leaking of brake fluid here, then you know your braking system needs an overhaul because there might be a problem somewhere surrounding its functioning.

It is better to choose OEM parts when it comes to the time for fixing them. Why? Because they fit perfectly well and ensure safety. For people who prefer doing their maintenance, the genuine Audi Brake Caliper is quite perfect. At AudiPartsGiant.com, we specialize in genuine Audi Brake Calipers only. Also, we offer an extensive online catalog with many categories, ample stock, and secure shopping. The Audi Brake Caliper is shipped directly from authorized Audi dealers at competitive prices. So trust us, and we will give you nothing but superior service. Depend on us for all your genuine parts needs, and then we will keep your automobile moving smoothly.

Audi Brake Caliper Parts and Q&A

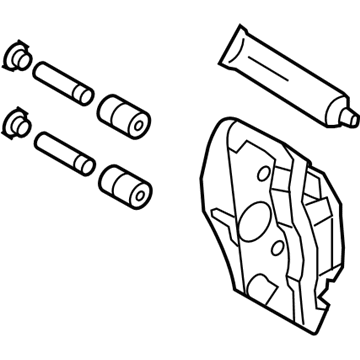

- Q: How to properly clean and reassemble a rear brake caliper on Audi 80?A:Start with wiping off the outer part of the calliper to keep out of the hole in the hose leading to hydraulic parts no foreign substance. Hold the calliper in a vice with the piston upwards and take off the piston dust cap in its groove. In the case of the Teves calliper a piece of wood in the jaws opposite the piston is inserted, and air pressure is used to push the piston out of the bore through the hydraulic fluid inlet. In the case of Girling calliper, the piston is screwed to the bore, and the screw is removed with an Allen key. Take the piston carefully off the bore, taking care not to scratch the surface, and remove the dust cap of the piston. Unscrew bleed screw and rinse with methylated spirit and dry all parts. Check the piston and bore to presence or absence of corrosion and scoring, check the automatic adjuster threads to determine their wear and inspect the calliper housing to confirm the absence of fluid leakage around the handbrake operating arm. Evaluate guide pins, seals, bushes, etc. in wear and replace parts when needed. In case the calliper and piston are in good conditions, take a repair kit of seals. To start reassembling, pour a small amount of brake fluid on the bore and piston surface, and put the piston seal into the bore groove. In the case of the Teves calliper, insert the clamping component in the calliper against the stop and make sure the threaded insert turns freely, then place the dust cap on the piston and connect it with the calliper but make sure that it fits centrally. The piston should be pressed in the bore with the help of a G-clamp and the dust cap should be clamped into position. In the case of Girling calliper, open the dust cap on the piston, drop it into the groove and screw the piston into the bore pressing hard. Install a new rubber seal on the bleed screw, grease the threads with the brake fluid, and screw it on. Girling callipers are also available in pre-filled new Girling callipers, with brake fluid and it is advisable to fill and bleed Girling and Teves callipers after overhaul. This can be done by ensuring the calliper has been mounted in a vice so that the hydraulic is exposed at the top, loosen the bleed screw, empire this to a brake fluid supply, fill until fluid is released without bubbles, tighten the bleed screw and seal the fluid inlet where required.

Related Audi Parts

Browse by Model

100 Brake Caliper 100 Quattro Brake Caliper 200 Brake Caliper 200 Quattro Brake Caliper 4000 Brake Caliper 4000 Quattro Brake Caliper 5000 Brake Caliper 5000 Quattro Brake Caliper 80 Brake Caliper 80 Quattro Brake Caliper 90 Brake Caliper 90 Quattro Brake Caliper A3 Brake Caliper A3 Quattro Brake Caliper A3 Sportback e-tron Brake Caliper A4 Brake Caliper A4 Quattro Brake Caliper A4 allroad Brake Caliper A5 Brake Caliper A5 Quattro Brake Caliper A5 Sportback Brake Caliper A6 Brake Caliper A6 Quattro Brake Caliper A6 allroad Brake Caliper A7 Quattro Brake Caliper A7 Sportback Brake Caliper A8 Brake Caliper A8 Quattro Brake Caliper Allroad Quattro Brake Caliper Cabriolet Brake Caliper Coupe Brake Caliper Coupe Quattro Brake Caliper Q3 Brake Caliper Q3 Quattro Brake Caliper Q4 e-tron Brake Caliper Q4 e-tron Sportback Brake Caliper Q5 Brake Caliper Q5 PHEV Brake Caliper Q5 Sportback Brake Caliper Q7 Brake Caliper Q8 Brake Caliper Q8 e-tron Brake Caliper Q8 e-tron Sportback Brake Caliper Quattro Brake Caliper R8 Brake Caliper RS Q8 Brake Caliper RS e-tron GT Brake Caliper RS3 Brake Caliper RS4 Brake Caliper RS5 Brake Caliper RS5 Sportback Brake Caliper RS6 Avant Brake Caliper RS6 Brake Caliper RS7 Brake Caliper RS7 Sportback Brake Caliper S3 Brake Caliper S4 Brake Caliper S5 Brake Caliper S5 Sportback Brake Caliper S6 Brake Caliper S7 Brake Caliper S7 Sportback Brake Caliper S8 Brake Caliper SQ5 Brake Caliper SQ5 Sportback Brake Caliper SQ7 Brake Caliper SQ8 Brake Caliper TT Brake Caliper TT Quattro Brake Caliper TT RS Quattro Brake Caliper TTS Quattro Brake Caliper V8 Quattro Brake Caliper allroad Brake Caliper e-tron GT Brake Caliper e-tron Quattro Brake Caliper e-tron S Brake Caliper e-tron S Sportback Brake Caliper e-tron Sportback Brake Caliper