×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi 4000 Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Calipers found

Audi 4000 Caliper Part Number: 811-615-124

$131.04 MSRP: $183.53You Save: $52.49 (29%)Ships in 1-2 Business DaysAudi 4000 Caliper Part Number: 811-615-123

$139.99 MSRP: $196.07You Save: $56.08 (29%)Ships in 1-2 Business DaysAudi 4000 Caliper Part Number: 853-615-424-X

$192.37 MSRP: $267.95You Save: $75.58 (29%)Ships in 1-2 Business DaysAudi 4000 Caliper Part Number: 853-615-423-X

$199.39 MSRP: $276.32You Save: $76.93 (28%)Ships in 1-2 Business Days

Audi 4000 Brake Caliper

Choose original equipment manufacturer Brake Caliper for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Brake Caliper at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi 4000 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your 4000 needs now.

Audi 4000 Brake Caliper Parts and Q&A

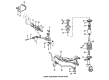

- Q: How to remove and refit brake calipers on Audi 4000?A:Start by peeling the disc pads. The second step is to remove the brake fluid reservoir filler cap, and put it on some polythene sheeting that is laid over the reservoir filler hole to enable the reservoir not to lose any fluid during the procedure. Alternatively, a brake hose clamp could also be installed on the hydraulic hose that is connected to the caliper. Unscrewing of the hydraulic hose union is not carried at this stage. In the case of the Teves caliper, unscrew the two bolts that hold the caliper to the suspension strut and hold the caliper, unscrew the caliper out of the hydraulic hose and insert the end of the hose. In the Girling caliper, loosen the upper guide pin using a spanner and loosen the upper caliper bolt making sure that the caliper is not suspended on the hydraulic hose. To disattach the caliper and take it off the hydraulic hose, un screw the caliper and then press the end of the hose. Unbolt the caliper bracket off the suspension strut, as required. Refitting constitutes the reversal of the disassembling steps, priming all the mating faces, all bolts and unions should be tightened to the designated torque and lastly, a bleeding of the hydraulic system.

- Q: How to clean and reassemble the Brake Caliper components for both Teves and Girling calipers on Audi 4000?A:Clean the exterior of the caliper, ensuring no foreign matter enters the hydraulic hose aperture. For the Teves caliper, press the mounting frame off the floating frame and separate the two frames. Place a block of wood in the floating frame and drive out the cylinder assembly using a soft metal drift. Use a foot pump or compressed air to blow the piston out of the cylinder, supporting the cylinder with the piston facing downwards to avoid injury. Carefully use a blunt screwdriver to prise the seal out of the piston bore without scratching the cylinder bore. Clean the caliper components thoroughly with methylated spirit and allow them to dry. Fit a new seal into the groove in the cylinder bore, applying a thin coat of brake cylinder paste to both the seal and the cylinder, then squeeze the piston into the cylinder using a vice with soft jaws. Rest the floating frame on the bench, insert the brake cylinder, and tap it fully into the frame. With the locating spring fitted to the mounting frame, press the mounting frame onto the floating frame, setting the piston cutaway at a 20° angle to the horizontal, which can be checked with a simple gauge made from card. For the Girling caliper, use a foot pump or compressed air to blow the piston out of the cylinder, placing a block of wood inside the frame to prevent damage to the piston, and remove the dust cap. Carefully prise the seal out of the piston bore with a blunt screwdriver, clean the components thoroughly with methylated spirit, and allow them to dry. Fit a new seal into the groove in the cylinder bore, applying a thin coat of brake cylinder paste to both the seal and the cylinder. Fit the dust cap onto the piston and then offer the piston up to the cylinder, fitting the sealing lip of the dust cap into the groove of the cylinder bore with a screwdriver. Smear brake cylinder paste over the piston and press it into the cylinder until the outer lip of the dust cap springs into place in the piston groove. Finally, check the guide pins, bolts, and dust caps for condition, renewing them if necessary, as the bolts are self-locking and should be replaced whenever removed.