×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi 100 Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

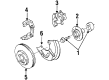

14 Brake Calipers found

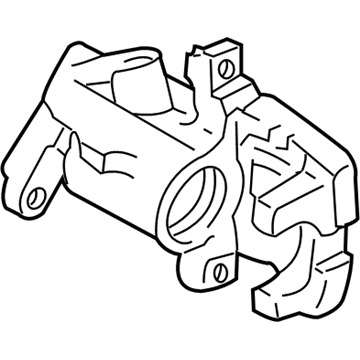

Audi 100 Caliper Part Number: 853-615-424-AX

$293.79 MSRP: $410.00You Save: $116.21 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 443-615-123-EX

$76.82 MSRP: $107.00You Save: $30.18 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 443-615-124-FX

$104.06 MSRP: $145.00You Save: $40.94 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 443-615-124-EX

$131.93 MSRP: $184.18You Save: $52.25 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 443-615-123-FX

$129.25 MSRP: $180.28You Save: $51.03 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 853-615-424-X

$192.37 MSRP: $267.95You Save: $75.58 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 4A0-615-424-X

$243.81 MSRP: $340.00You Save: $96.19 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 4A0-615-123-A

$307.02 MSRP: $430.00You Save: $122.98 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 4A0-615-423-X

$272.37 MSRP: $380.00You Save: $107.63 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 4A0-615-124-A

$325.44 MSRP: $455.80You Save: $130.36 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 443-615-423-AX

$310.45 MSRP: $433.33You Save: $122.88 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 443-615-424-AX

$310.45 MSRP: $433.33You Save: $122.88 (29%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 853-615-423-X

$199.39 MSRP: $276.32You Save: $76.93 (28%)Ships in 1-2 Business DaysAudi 100 Caliper Part Number: 1H0-615-424-DX

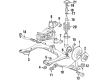

Audi 100 Brake Caliper

Choose original equipment manufacturer Brake Caliper for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Brake Caliper at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi 100 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your 100 needs now.

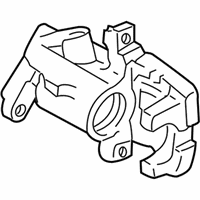

Audi 100 Brake Caliper Parts and Q&A

- Q: How to disconnect and reconnect the Brake Caliper hydraulic union on Audi 100?A:In models that have ABS, it is important to disconnect the battery first before disconnecting any braking system hydraulic union and never reconnect battery until the hydraulic system is reconnected and fluid in the reservoir capped to ensure that no air enters the hydraulic unit which would need special Audi/VAG test equipment to bleed. You should know about the dangers of hydraulic fluid and asbestos dust before you commence work. Refitting should be done using new guide pin bolts. To start off, you need to chock the front wheels, jack underneath the back of the car, and hold it on axle stands and remove at least one rear wheel bolt so that you leave the Brake Disc in place. Pull out the handbrake lever and pull the handbrake cable adjuster to maximum freeplay. Disconnect the handbrake cable with the caliper lever, the retaining clip, and the outer cable with the caliper body. Reduce the loss of fluids by removing cap of the master cylinder reservoir and sealing it with polythene or making a Brake Hose clamp. Wipe the surroundings of the caliper brake hose and loosen the union. Bolt the caliper guide pin with a thin open ended spanner and dismantling the old bolts to avoid rotation. Loosen the brake caliper by removing it out of its mounting bracket and unscrewing it out of the brake hose to prevent loss of fluid and so that no dirt can get into it. Spray down any spilled fluid with cold water, leave the brake pads in the caliper bracket. One can not revamp the brake caliper handbrake mechanism; when defective or dripping, the caliper assembly needs to be replaced. Clean the dust and dirt off the bench without breathing it in. It is recommended to take the piston out of the caliper bore using circlip pliers by turning it anti-clockwise, and then remove it manually. Carefully remove dust seal and hydraulic seal out of the caliper bore. Take out the guide pins and guide sleeve gaiters and check all the parts to have them renewed, but do not dismantle the handbrake mechanism. Always dry the parts when putting them back. Wet the piston and new piston seal with clean hydraulic fluid, and onto the cylinder bore surface apply clean fluid by finger action and the new seal is installed. Install the new dust seal to the piston and push it into the cylinder bore turning clockwise until completely retracted and the inner lip of the dust seal has seated. Place grease on the guide pins, install new gaiters and insert the pins in the caliper mounting bracket making sure to fit. Before refitting, fill the caliper with fresh hydraulic fluid by turning the bleed screw loosely and pumping until all the bubbles are forced out. Make sure that the brake pads are properly mounted in the caliper bracket, screw the caliper on the brake hose. Place the caliper on the pads and install the new guide pin bolts and tighten them to the required torque. Take out any clamps and polythene and tight the brake hose union securely. Bleed Hydraulic system, taking note that in case special care was given to keep the quantity of fluid entering the system to a minimum it should just be required to bleed corresponding brake at the rear. Once again connect the handbrake cable to the caliper and fix it with the retaining clip and merit the cable. Install the roadwheel once again, get the vehicle down to the ground and crimp the roadwheel bolts to the desired torque.

- Q: What precautions should be taken when working on Brake Caliper models equipped with ABS and their braking systems on Audi 100?A:Models with ABS are to be handled with caution, the battery should not be disconnected, and any hydraulic union to the braking system should not be disconnected without first topping up the hydraulic fluid as the failure to do so can result in air entering the hydraulic unit, and this may require special Audi/VAG test equipment to perform bleeding. Hydraulic fluid and asbestos dust are also dangerous and should be taken into consideration before starting the working process. Removal of the brake caliper requires application of handbrake, the front of the vehicle to be jacked then supported on axle stands and at least one wheel bolt reattached to assure that the Brake Disc remains in place. Reduce fluid loss by eliminating cap on the master cylinder reservoir and clamping it with polythene or brake hose. Unscrew the union nut, plugging the end of the pipe, disconnect wiring of the brake pad wear sensor, clean the space around the caliper brake pipe union, and clean the inside of the union with the pipe end. Carefully take the retaining pad spring, end caps on the guide bushes, and ease the caliper guide bolts to be careful, slowly lifting the caliper out which then is free of the pad wear sensor wiring. Clean all parts on the bench and do not inhale dust, remove piston, and scrape dust seal and hydraulic seal, being careful not to damage caliper bore. Wash and dry all the parts using the right solvents and examine the parts including checking on wear and damages, replacing damaged sections. In case the assembly is reusable, a repair kit should be used and all rubber seals should be renewed. When reassembling make sure that it is clean and dry, wet the piston and new seal with hydraulic fluid, and install the new piston seal by hands only. Install dust seal and very careful ease the piston into the cylinder bore, making sure the inner lip of the dust seal is in position. In case of renewing guide bushes, press the novel ones into place. Before refitting, ensure that the brake pads are in place and that the caliper is maneuvered to get the pad wear sensor wiring in place and then fill the caliper with fresh hydraulic fluid. Install the caliper guide bolts and end caps once more, reattach the brake pipe and ensure that all the bolts are tightened to appropriate torque values. Install the pad retaining spring, make sure that the wiring is appropriately routed, and that the connector of the wiring is attached back in place. Lastly, disassemble clamps, seals, bleed hydraulic system, replace the roadwheel, lower the vehicle, and clamp the roadwheel bolts with correct amount of torque.