×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi 90 Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Brake Calipers found

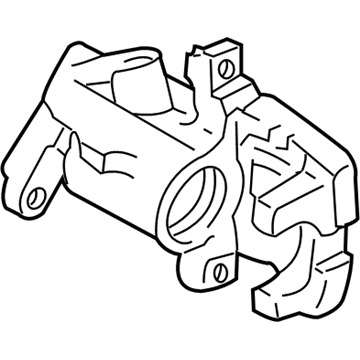

Audi 90 Caliper Part Number: 853-615-423-AX

$293.79 MSRP: $410.00You Save: $116.21 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 853-615-424-AX

$293.79 MSRP: $410.00You Save: $116.21 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 443-615-124-FX

$104.06 MSRP: $145.00You Save: $40.94 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 443-615-123-FX

$129.25 MSRP: $180.28You Save: $51.03 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 853-615-424-X

$192.37 MSRP: $267.95You Save: $75.58 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 895-615-124

$282.03 MSRP: $395.00You Save: $112.97 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 8A0-615-423-X

$243.81 MSRP: $340.00You Save: $96.19 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 8A0-615-424-X

$243.81 MSRP: $340.00You Save: $96.19 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 893-615-123-B

$296.31 MSRP: $415.00You Save: $118.69 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 893-615-124-B

$296.31 MSRP: $415.00You Save: $118.69 (29%)Ships in 1-2 Business DaysAudi 90 Axle Assembly Part Number: 895-615-123

$310.59 MSRP: $435.00You Save: $124.41 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 895-615-123-A

$351.29 MSRP: $492.00You Save: $140.71 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 895-615-124-A

$351.29 MSRP: $492.00You Save: $140.71 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 443-615-423-AX

$310.45 MSRP: $433.33You Save: $122.88 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 443-615-424-AX

$310.45 MSRP: $433.33You Save: $122.88 (29%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 443-615-423-X

$189.67 MSRP: $262.70You Save: $73.03 (28%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 853-615-423-X

$199.39 MSRP: $276.32You Save: $76.93 (28%)Ships in 1-2 Business DaysAudi 90 Caliper Part Number: 443-615-424-X

$196.04 MSRP: $233.46You Save: $37.42 (17%)Ships in 1-2 Business Days

Audi 90 Brake Caliper

Choose original equipment manufacturer Brake Caliper for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Brake Caliper at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi 90 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your 90 needs now.

Audi 90 Brake Caliper Parts and Q&A

- Q: How to clean and reassemble a front Brake Caliper on Audi 90?A:Clean the exterior of the calliper, ensuring no foreign matter enters the hydraulic hose aperture, then mount the calliper in a vice. Prise the dust cap(s) from the groove(s) in the calliper and place a piece of wood in the calliper jaws, opposite the piston(s). Use air pressure from a foot pump through the hydraulic fluid inlet to force the piston(s) from the bore(s), removing each piston separately if twin pistons are fitted by blocking one with wood. Use a pad of rubber on wood and a G-clamp to cover the open cylinder while removing the remaining piston. Carefully prise the piston seal(s) from the bore(s) without scratching the bore surface and remove the dust cap(s) from the piston(s). Unscrew the bleed screw, clean all components with methylated spirit, and allow them to dry. Examine the piston and bore surfaces for corrosion and scoring; if evident, the calliper should be renewed completely, but if the surfaces are good, obtain a repair kit with new seals. Begin reassembly by smearing a little brake cylinder fluid on the bore(s) and piston(s), then locate the piston seal(s) in the bore groove(s). To refit the piston, position the dust cap on the plain end of the piston, offer the piston to the calliper, and use a screwdriver to lift the dust cap into the groove, pressing the piston into the bore until the dust cap snaps into the groove on the outer end. Fit a new rubber cap on the bleed screw, apply a little brake fluid to the threads, and tighten the bleed screw into the calliper. For the Girling calliper, apply a little grease to the guide pins before inserting them, and for the Teves calliper, check the guide pin bushes made of Teflon and renew them if necessary, also checking the rubber bushes.