×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

120 Oil Pans found

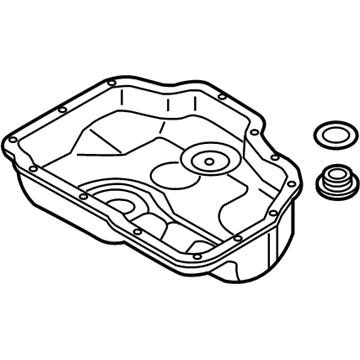

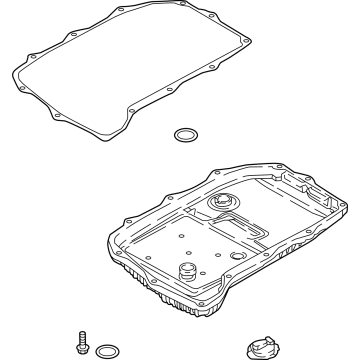

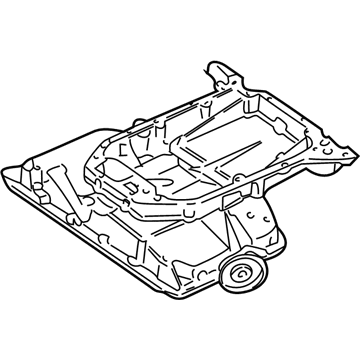

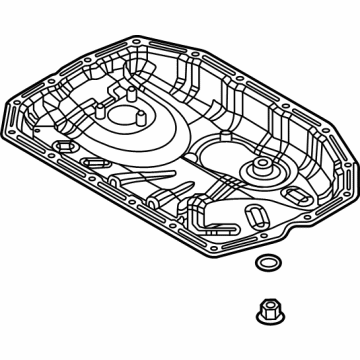

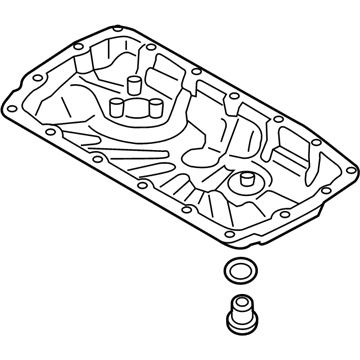

Audi Transmission Pan Part Number: 0GC-325-201-H

$41.13 MSRP: $56.65You Save: $15.52 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cover; Side Cover, Transmission Pan

- Replaced by: 0GC-325-201-L

- Replaces: 0GC-325-201-E

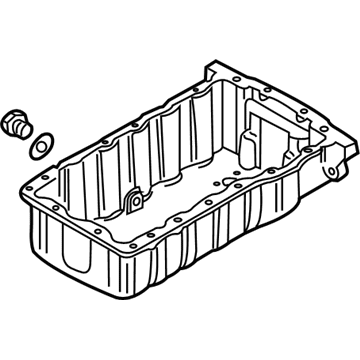

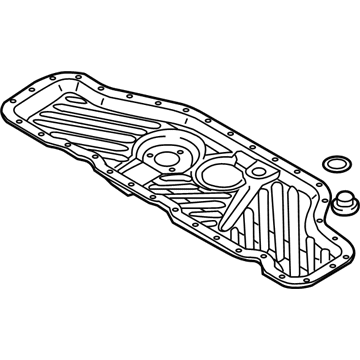

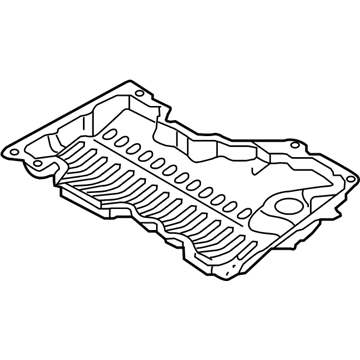

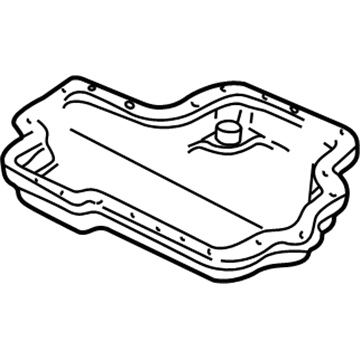

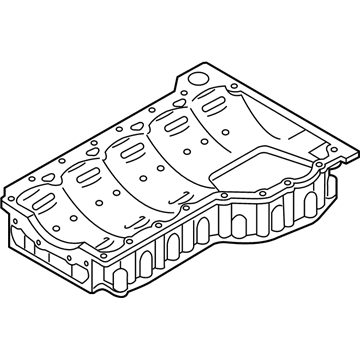

Audi Oil Pan Part Number: 058-103-603-A

$76.93 MSRP: $107.75You Save: $30.82 (29%)Ships in 1-2 Business DaysAudi Oil Pan Part Number: 058-103-598-C

$86.51 MSRP: $121.16You Save: $34.65 (29%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 058-103-603-C

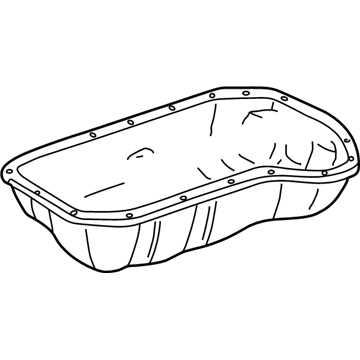

Audi Lower Oil Pan Part Number: 059-103-602-AB

$174.49 MSRP: $244.37You Save: $69.88 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Lower Oil Pan

Audi Lower Oil Pan Part Number: 059-103-602-F

$174.49 MSRP: $244.37You Save: $69.88 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Oil Pan

- Position: Lower

Audi Lower Oil Pan Part Number: 078-103-604-AA

$164.07 MSRP: $229.78You Save: $65.71 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Lower Oil Pan

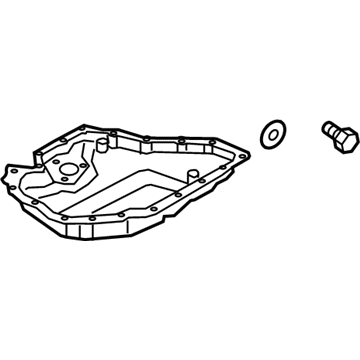

Audi Transmission Pan Part Number: 0DK-321-359-A

$169.92 MSRP: $237.99You Save: $68.07 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Oil Pan, Transmission Pan

Audi Lower Oil Pan Part Number: 06J-103-600-AF

$189.72 MSRP: $265.71You Save: $75.99 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Oil Pan

- Position: Lower

- Replaces: 06J-103-600-G, 06J-103-600-E, 06J-103-600-T

Audi Oil Pan Part Number: 038-103-601-AQ

$171.36 MSRP: $240.00You Save: $68.64 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump

- Replaces: 038-103-601-MA

Audi Lower Oil Pan Part Number: 06L-103-598-S

$136.84 MSRP: $191.65You Save: $54.81 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Lower Oil Pan, Oil Pan

Audi Lower Oil Pan Part Number: 04L-103-602-A

$205.98 MSRP: $288.47You Save: $82.49 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump

- Position: Lower

Audi Transmission Pan Part Number: 0D5-398-009-B

$197.53 MSRP: $276.65You Save: $79.12 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Filter, Oil Pan, Transmission Pan

- Replaces: 0D5-398-009-A

Audi Oil Pan Part Number: 078-103-604-B

$195.16 MSRP: $273.33You Save: $78.17 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump

Audi Oil Pan Part Number: 077-103-602-A

$197.54 MSRP: $276.67You Save: $79.13 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump

Audi Lower Oil Pan Part Number: 0P2-103-602-A

$233.24 MSRP: $326.66You Save: $93.42 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Pan; Lower Oil Pan

Audi Lower Oil Pan Part Number: 06L-103-600-F

$235.62 MSRP: $330.00You Save: $94.38 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Oil Pan

- Position: Lower

Audi Lower Oil Pan Part Number: 06M-103-602-Q

$240.38 MSRP: $336.68You Save: $96.30 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Lower Oil Pan, Oil Pan

- Replaces: 06M-103-604-Q

Audi Upper Oil Pan Part Number: 07K-103-603-C

$263.93 MSRP: $369.65You Save: $105.72 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Oil Pan

- Position: Upper

Audi Oil Pan Part Number: 077-103-602

$210.63 MSRP: $295.00You Save: $84.37 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump

Audi Lower Oil Pan Part Number: 06L-103-598-R

$248.71 MSRP: $348.33You Save: $99.62 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Sump; Lower Oil Pan, Oil Pan

| Page 1 of 6 |Next >

1-20 of 120 Results

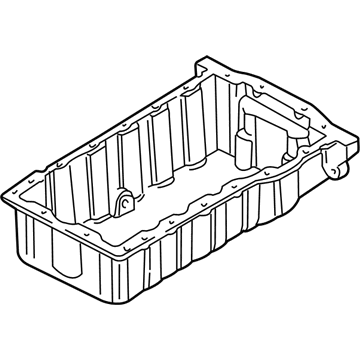

Audi Oil Pan

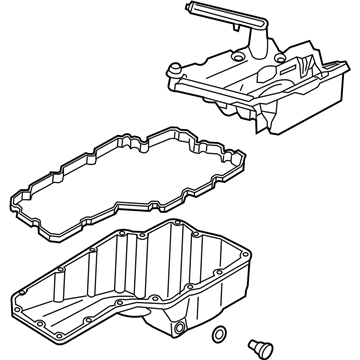

The oil pan is a vital part of the cooling system in your car since it functions as an oil reservoir when the engine stops and the oil drains from its crankcase. The Audi oil pan is usually made of thin steel and shaped into a deeper section. The location of the oil pan is where the oil pump is. As time goes on, leaks or cracks may develop in this pan. For your safety, please check this part frequently. If there is a constant oil leak under your vehicle or you smell smoke from the engine area, your oil pan could be affected. You can replace your oil pan with quite significant savings.

It is better to choose OEM parts when it comes to the time for fixing them. Why? Because they fit perfectly well and ensure safety. For people who prefer doing their maintenance, the genuine Audi Oil Pan is quite perfect. At AudiPartsGiant.com, we specialize in genuine Audi Oil Pans only. Also, we offer an extensive online catalog with many categories, ample stock, and secure shopping. The Audi Oil Pan is shipped directly from authorized Audi dealers at competitive prices. So trust us, and we will give you nothing but superior service. Depend on us for all your genuine parts needs, and then we will keep your automobile moving smoothly.

Audi Oil Pan Parts and Q&A

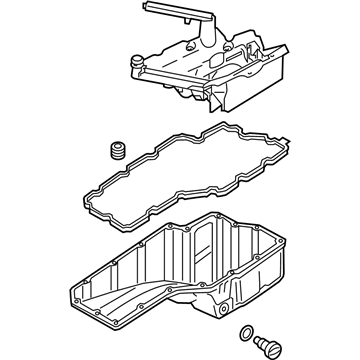

- Q: How to remove and refit the oil pan for 4-cylinder petrol engines on Audi 100?A:In an attempt to remove the engine, then jack up the front part of the vehicle, then place it on axle stands with the jack and place the handbrake. Remove the undershield under the engine. Locate a container below the oil pan and unscrew the drain plug and drain out the engine oil, cleaning and replacing the plug afterwards. Take off the dipstick and use a hoist to lift the weight of the engine. Unscrew the engine mounting lower nuts, unbolt and remove the transmission front cover. Place a trolley jack beneath the front suspension crossmember and undo the crossmember front mounting bolts and lower it slightly. Unscrew and remove the oil pan bolts, and remove the oil pan and the gasket, tapping with a mallet gently where needed. To refit, hold the contact faces of the oil pan and block clean, apply a new gasket on the oil pan and fit it to the block, without jointing compound, screwing the bolts in a diagonal order to the stated torque. Lift up the front suspension crossmember, align the mounting bolts, place the engine on top of the crossmember and take the hoist off. Install the engine mounting lower nuts, once more connect the transmission front cover, and tighten the bolts. Lastly, place the engine dipstick in once more, screw the undershield back on, put the car in place on the ground and add the right amount of oil to the engine.

- Q: What steps does Audi recommend for renewing the oil pan when removing the intermediate plate on Audi A3?A:Audi insists that on models fitted with an intermediate plate between the oil pump/balancer shaft housing and the engine block, the plate must be renewed when the oil pan is removed. To begin removal, apply the handbrake, jack up the front of the vehicle, and support it on axle stands. Release the fasteners, remove the engine undertray, and detach the undertray bracket. Position a container beneath the oil pan, unscrew the drain plug, and drain the engine oil, cleaning the plug and renewing the washer if necessary before refitting and tightening it. Remove the dipstick, auxiliary drivebelt, and disconnect the oil temperature sensor wiring plug from the base of the oil pan. Detach the refrigerant support pipe and position the air conditioning compressor to one side without disconnecting the refrigerant pipes. Unbolt the stop bracket from the front of the engine, unclip the vehicle height sensor actuator rod if applicable, and detach the inboard clamps from the front anti-roll bar. Cut the plastic cable ties to detach the starter motor cables, unscrew and remove the nuts from the bottom of each engine mounting, and remove the engine top cover along with the inlet ducting. Connect a suitable hoist to the engine and raise it carefully, then mark the fitted position of the subframe, position a workshop trolley jack to take the weight, and lower the front subframe after undoing the bolts. Gradually unscrew and remove the oil pan bolts in a diagonal pattern, noting that on manual transmission models, the two rear oil pan bolts are accessed through a cut-out in the flywheel. If the oil pan is stuck, tap it gently with a mallet to free it. For refitting, thoroughly clean the contact faces of the oil pan, using a rotary wire brush to remove sealant. Refit the oil pan, tightening the retaining bolts hand-tight initially, ensuring that if the engine is out of the car, the rear edge of the oil pan overhangs the rear edge of the cylinder block by 0.8 mm. Progressively tighten the oil pan bolts in a diagonal pattern to the specified torque, allowing at least 30 minutes for the intermediate plate sealant to set before filling the engine with oil. The remaining refitting procedure is a reversal of removal, ensuring that all nuts and bolts are tightened to the specified torque, and finally, fill the engine with the correct quantity of oil.

Related Audi Parts

Browse by Model

100 Oil Pan 100 Quattro Oil Pan 200 Oil Pan 200 Quattro Oil Pan 5000 Oil Pan 5000 Quattro Oil Pan 80 Oil Pan 80 Quattro Oil Pan 90 Oil Pan 90 Quattro Oil Pan A3 Oil Pan A3 Quattro Oil Pan A3 Sportback e-tron Oil Pan A4 Oil Pan A4 Quattro Oil Pan A4 allroad Oil Pan A5 Oil Pan A5 Quattro Oil Pan A5 Sportback Oil Pan A6 Oil Pan A6 Quattro Oil Pan A6 allroad Oil Pan A7 Quattro Oil Pan A7 Sportback Oil Pan A8 Oil Pan A8 Quattro Oil Pan Allroad Quattro Oil Pan Cabriolet Oil Pan Coupe Quattro Oil Pan Q3 Oil Pan Q3 Quattro Oil Pan Q5 Oil Pan Q5 PHEV Oil Pan Q5 Sportback Oil Pan Q7 Oil Pan Q8 Oil Pan R8 Oil Pan RS Q8 Oil Pan RS3 Oil Pan RS4 Oil Pan RS5 Oil Pan RS5 Sportback Oil Pan RS6 Avant Oil Pan RS7 Oil Pan RS7 Sportback Oil Pan S3 Oil Pan S4 Oil Pan S5 Oil Pan S5 Sportback Oil Pan S6 Oil Pan S7 Oil Pan S7 Sportback Oil Pan S8 Oil Pan SQ5 Oil Pan SQ5 Sportback Oil Pan SQ7 Oil Pan SQ8 Oil Pan TT Oil Pan TT Quattro Oil Pan TT RS Quattro Oil Pan TTS Quattro Oil Pan V8 Quattro Oil Pan allroad Oil Pan