×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

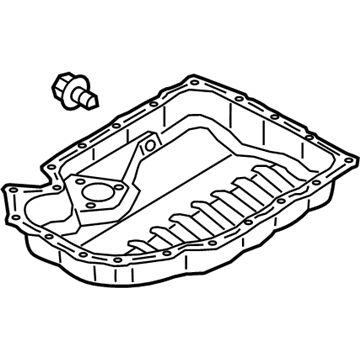

Genuine Audi A4 Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Oil Pans found

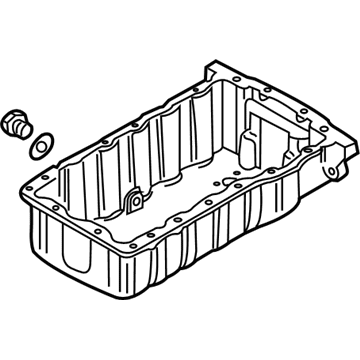

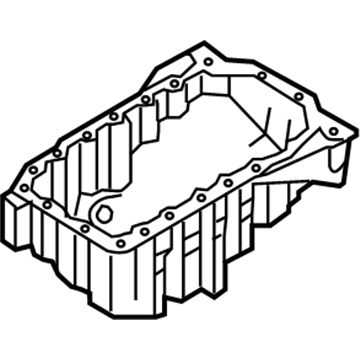

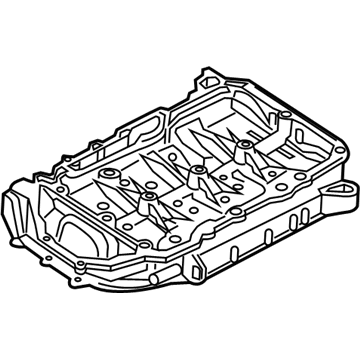

Audi A4 Oil Pan Part Number: 058-103-603-A

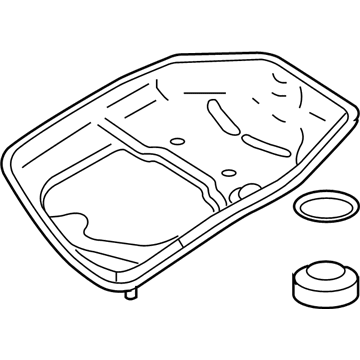

$76.93 MSRP: $107.75You Save: $30.82 (29%)Ships in 1-2 Business DaysAudi A4 Oil Pan Part Number: 058-103-598-C

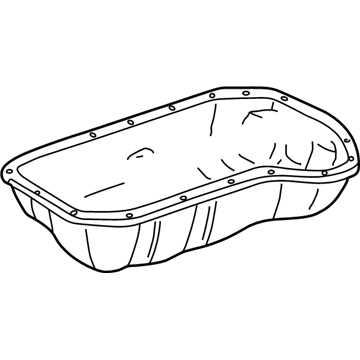

$86.51 MSRP: $121.16You Save: $34.65 (29%)Ships in 1-2 Business DaysAudi A4 Lower Oil Pan Part Number: 078-103-604-AA

$164.07 MSRP: $229.78You Save: $65.71 (29%)Ships in 1-2 Business DaysAudi A4 Lower Oil Pan Part Number: 06L-103-598-R

$248.71 MSRP: $348.33You Save: $99.62 (29%)Ships in 1-2 Business DaysAudi A4 Lower Oil Pan Part Number: 06H-103-600-AA

$202.29 MSRP: $283.32You Save: $81.03 (29%)Ships in 1-2 Business DaysAudi A4 Oil Pan Part Number: 06B-103-601-CD

$242.76 MSRP: $340.00You Save: $97.24 (29%)Ships in 1-2 Business DaysAudi A4 Oil Pan Part Number: 06B-103-601-CG

$210.48 MSRP: $294.79You Save: $84.31 (29%)Ships in 1-2 Business DaysAudi A4 Oil Pan Part Number: 06C-103-604-C

$242.76 MSRP: $340.00You Save: $97.24 (29%)Ships in 1-2 Business DaysAudi A4 Lower Oil Pan Part Number: 06E-103-604-F

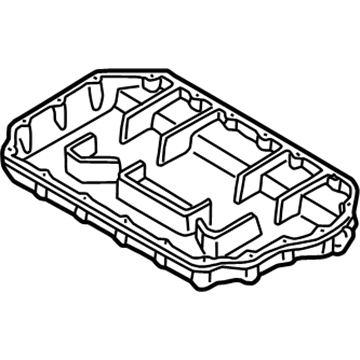

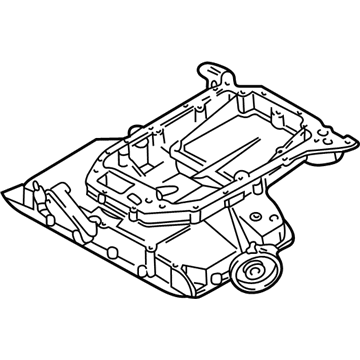

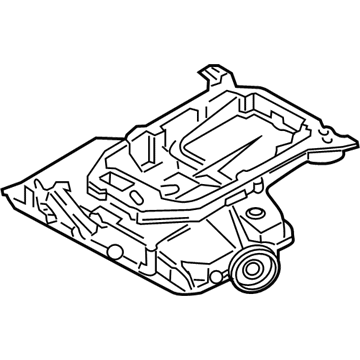

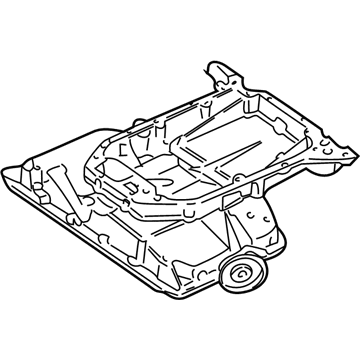

$298.32 MSRP: $417.82You Save: $119.50 (29%)Ships in 1-2 Business DaysAudi A4 Upper Oil Pan Part Number: 06L-103-603-BP

$336.77 MSRP: $471.66You Save: $134.89 (29%)Ships in 1-2 Business DaysAudi A4 Upper Oil Pan Part Number: 06L-103-603-AT

$359.38 MSRP: $503.34You Save: $143.96 (29%)Ships in 1-2 Business DaysAudi A4 Upper Oil Pan Part Number: 06H-103-603-AN

$350.68 MSRP: $491.15You Save: $140.47 (29%)Ships in 1-2 Business DaysAudi A4 Oil Pan Part Number: 078-103-603-AM

$381.12 MSRP: $533.79You Save: $152.67 (29%)Ships in 1-2 Business DaysAudi A4 Upper Oil Pan Part Number: 078-103-603-AG

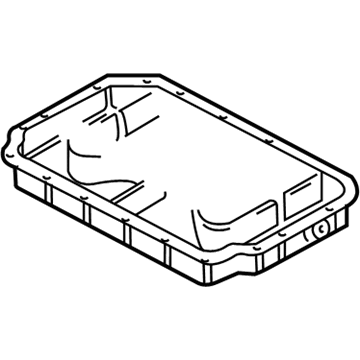

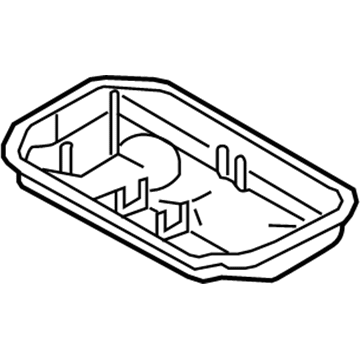

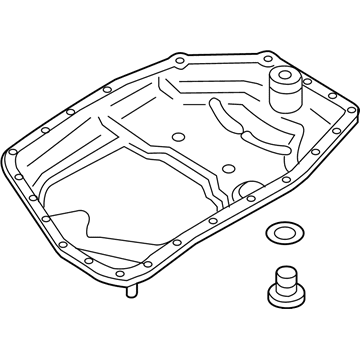

$448.63 MSRP: $628.33You Save: $179.70 (29%)Ships in 1-2 Business DaysAudi A4 Transmission Pan Part Number: 0B6-321-359

$527.16 MSRP: $738.31You Save: $211.15 (29%)Ships in 1-2 Business DaysAudi A4 Transmission Pan Part Number: 0BK-321-359

$534.18 MSRP: $748.15You Save: $213.97 (29%)Ships in 1-2 Business DaysAudi A4 Oil Pan Part Number: 06C-103-601-D

$537.88 MSRP: $753.33You Save: $215.45 (29%)Ships in 1-2 Business DaysAudi A4 Transmission Pan Part Number: 09L-321-359

$586.06 MSRP: $820.82You Save: $234.76 (29%)Ships in 1-2 Business DaysAudi A4 Oil Pan Part Number: 078-103-603-M

$581.91 MSRP: $815.00You Save: $233.09 (29%)Ships in 1-2 Business DaysAudi A4 Upper Oil Pan Part Number: 06E-103-601-N

$770.51 MSRP: $996.14You Save: $225.63 (23%)Ships in 1-2 Business Days

Audi A4 Oil Pan

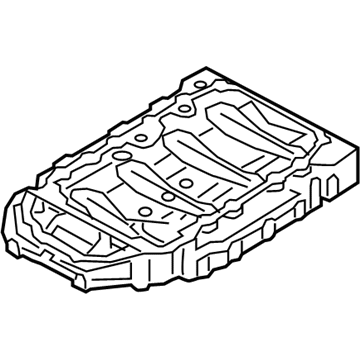

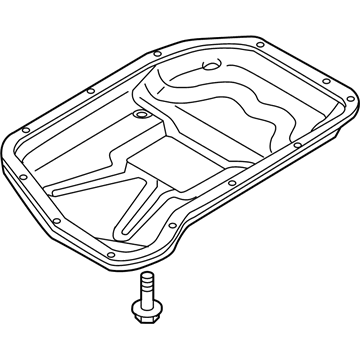

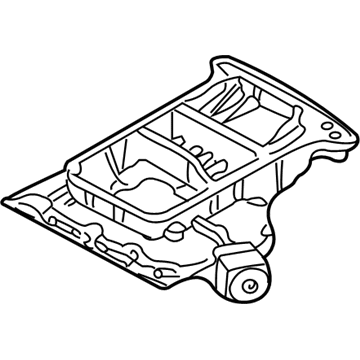

The main oil reservoir of the engine is the Audi A4 Oil Pan, which contains the lubricant that ensures the internal parts slide smoothly rather than grind. The majority of road models by Audi use a wet sump design, thus the Oil Pan is mounted below the block, whereby gravity allows the spent oil to settle and then be pumped back into the block. The design has the benefit of maximizing storage by locating the sump low and at the cost of elevating the engine slightly, as this will make the lubrication circuit simple and light. In fast bends, the oil will rise to one side, but internal baffles will contain the slosh to allow normal driving at reasonable cost. More exotic dry-sump designs incorporate separate scavenge pumps and an external tank, but most Audi cars such as the A4 model use the wet system as it does not add additional weight or complexity. Regular checks of the Oil Pan gasket will stop any leakage that may empty the supply, and replacement of a dented Oil Pan is extremely important since a deformed sealing surface cannot keep the pressure. That sump will ensure that high-efficiency engines installed on Audi cars are kept lubricated even during city runs and highway sprints. The simple-looking pressed-steel or cast-alloy pan might appear to be of minor importance, but it is a key component of any Audi powertrain, storing, cooling, and directing the oil where it is required.

Choose original equipment manufacturer Oil Pan for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Oil Pan at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A4 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A4 needs now.

Audi A4 Oil Pan Parts and Q&A

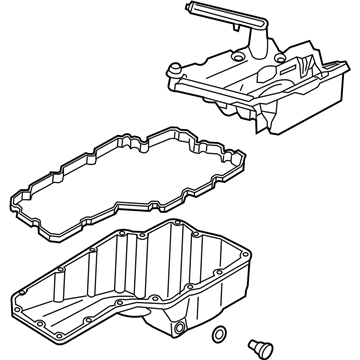

- Q: How to remove and install the oil pan for a V6 engines on Audi A4?A:Engines that have V6 utilize a two piece oil pan with the top section of the oil pan needing the engine to be raised and the subframe of the front suspension to be lowered and removed. To have the lower oil pan, an individual must first ensure that the parking brake is set and the rear wheels are blocked and then lift the front part of the vehicle and place it safely on jackstands. The second step involves the removal of splash shield underneath the engine and emptying engine oil, then the oil dipstick. Unclamped the refrigerant line clamps to the oil pan and make sure that the lines are stored without bending the metal section. On 3.0L engines, loosen the bolts holding the automatic transmission fluid lines to the oil pan, on 3.2L engines loosen the stabilizer bar bushing bolt, and lower the stabilizer bar and on the 3.0L engines loosen the engine oil cooler bolts and then leave it in place. Then unbolt the oil pan, and hit the oil pan with a mallet by a gentle stroke when it is stuck. To install it, use a scraper to remove all remnants of old sealant or gasket material on the upper and lower sides of the oil pan, cleaning the surfaces of the mating areas with brake system cleaner. Be sure the threaded bolt holes in the upper oil pan are clean, and check the oil pan flange against distortion, removing any nicks or burrs as required. Put the oil pan flange with a 1/16-inch bead of RTV sealant and it is important to make sure that the oil pan is installed in less than five minutes or the sealant will not stick. Install carefully on the upper oil pan the oil pan and loosely add the oil pan bolts and then tighten them in a criss cross manner involving the middle of the bolts towards the outer ones to the recommended torque. The rest of the process is the opposite of the order of removal, and in the case of 3.2L engines, the oil cooler must be replaced with new gaskets and O-rings where applicable. Lastly, start the engine to verify the presence of oil pressure, leakage and before adding oil, observe instructions to the manufacturers of sealants on the speed of curing of the sealant.

- Q: How to remove and install the oil pan for Four-cylinder engines on Audi A4?A:To change the oil pan, first of all, park the car with the parking brake and block the back wheels, and then raise the front part of the car and place it accurately on jackstands. Disengage the splash shield beneath the engine and position radiator support panel in service position being careful not to obstruct front of the engine by removing the front bumper. Drain the engine oil, then clean the oil dipstick, the drivebelt and the engine cooling fan. Unscrew the air conditioning compressor and fix it aside, and then take off the front torque rod. Unhook the starter motor cables under the Engine Mount and unhook the electrical connector under the bottom of the oil pan to the oil temperature sending unit. On 1.8L models, relax the rear bolt on the right-hand transmission mount and disassemble the front bolt, and repeat on the left-hand one in automatic transmission models. Unscrew the left hand transmission mount nut on the manual transmission until it is even with the end of the bolt. Attach an engine support block to the top of the engine and lift it safely, with the support of the front of the suspension subframe by a floor jack. Unscrew the front stabilizer bar bracket bolts and, where provided, disconnect the level control link of the front suspension. Withdraw the left engine mount and bracket of the engine block, unscrew the flange bolts and disconnect the turbocharger oil return line of the oil pan, placing it somewhere out of the way, and taking off the gasket. Take the subframe front bolts out and tilt the front of the subframe low enough that ends that the oil pan can be removed, but make sure the rear subframe bolts are not taken out. Unscrew and loosen the oil pan bolts, revealing the two rear bolts either with a cut out in the Flywheel in the event of a manual transmission model. Take out the gasket and the oil pan, and tap it lightly with a mallet. Installation requires the removal of prior sealant using a scraper on the block and on the oil pan to clean up the mating surfaces. Make sure that the threaded holes on the block are clean and verify the distortion of the oil pan flange. Check the oil pump pick up tube assembly, cracks and an obstructed strainer and re-clean and install using a new O-ring or gasket, where a blockage may have been removed. Use 1/8-inch bead of RTV sealant to the oil pan flange and place the oil pan on the engine block attaching the bolts and inserting them with the correct torque values. The rest of installation is in reverse sequence of the one taken off and care should be taken to follow the curing times specified by the manufacturer of the sealant before the addition of oil. Lastly, start the engine and ensure there is no oil leakage or pressure.

Related Audi A4 Parts

Browse by Year

2020 Oil Pan 2019 Oil Pan 2018 Oil Pan 2017 Oil Pan 2016 Oil Pan 2015 Oil Pan 2014 Oil Pan 2013 Oil Pan 2012 Oil Pan 2011 Oil Pan 2010 Oil Pan 2009 Oil Pan 2008 Oil Pan 2007 Oil Pan 2006 Oil Pan 2005 Oil Pan 2004 Oil Pan 2003 Oil Pan 2002 Oil Pan 2001 Oil Pan 2000 Oil Pan 1999 Oil Pan 1998 Oil Pan 1997 Oil Pan 1996 Oil Pan