×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

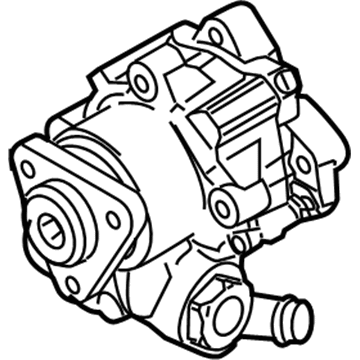

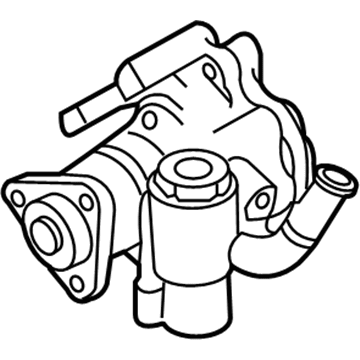

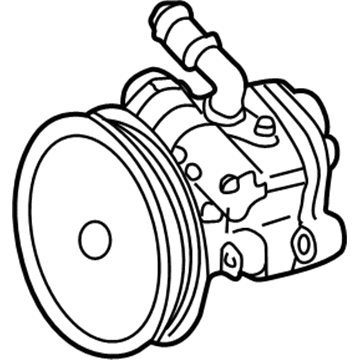

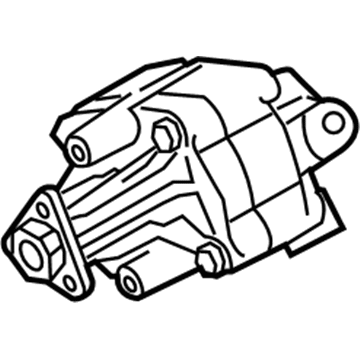

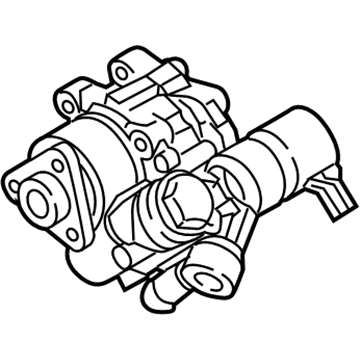

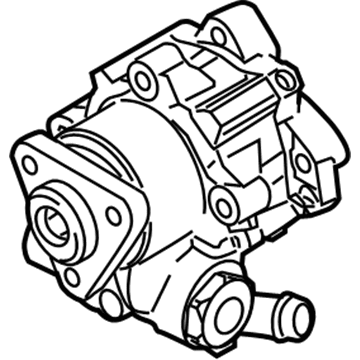

Genuine Audi Power Steering Pump

Power Steering Pump Unit- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

60 Power Steering Pumps found

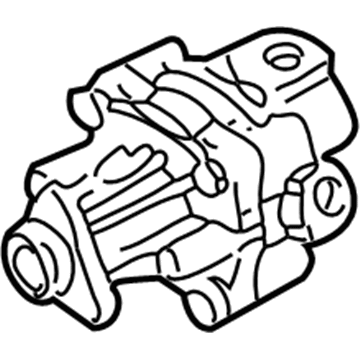

Audi Power Steering Pump Part Number: 8D0-145-156-F

$241.57 MSRP: $338.33You Save: $96.76 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

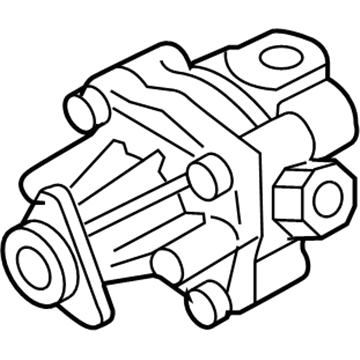

Audi Power Steering Pump Part Number: 8E0-145-155-F

$306.67 MSRP: $429.52You Save: $122.85 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

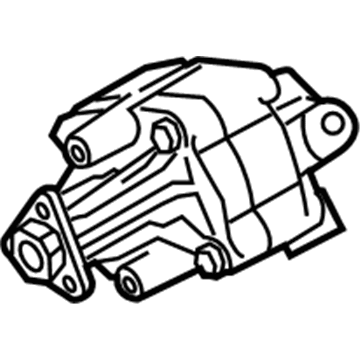

Audi Power Steering Pump Part Number: 7L8-422-153-D

$328.44 MSRP: $460.00You Save: $131.56 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

- Replaces: 7L8-422-153-A, 7L8-422-153-B

Audi Power Steering Pump Part Number: 026-145-155-BX

$327.33 MSRP: $458.33You Save: $131.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

- Replaces: 026-145-155-B

Audi Power Steering Pump Part Number: 3B7-422-154-A

$385.56 MSRP: $540.00You Save: $154.44 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

- Replaces: 4B0-145-156-A

Audi Power Steering Pump Part Number: 8N0-145-154-A

$386.75 MSRP: $541.67You Save: $154.92 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

Audi Power Steering Pump Part Number: 8D0-145-156-NX

$368.10 MSRP: $513.33You Save: $145.23 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

- Replaces: 8D0-145-156-N

Audi Power Steering Pump Part Number: 4B0-145-156-R

$451.01 MSRP: $631.67You Save: $180.66 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

Audi Power Steering Pump Part Number: 4B0-145-156-N

$471.24 MSRP: $660.00You Save: $188.76 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

Audi Power Steering Pump Part Number: 4F0-145-155-C

$509.32 MSRP: $713.33You Save: $204.01 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

Audi Power Steering Pump Part Number: 7L8-422-154-J

$686.63 MSRP: $887.70You Save: $201.07 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

- Replaces: 7L8-422-154-H, 7L8-422-154-F, 7L8-422-154-G

Audi Power Steering Pump Part Number: 4D0-145-155-K

$616.42 MSRP: $796.92You Save: $180.50 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

Audi Power Steering Pump Part Number: 8K0-145-153-F

$592.01 MSRP: $829.15You Save: $237.14 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

Audi Power Steering Pump Part Number: 8E0-145-153-J

$722.91 MSRP: $934.60You Save: $211.69 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

- Replaces: 8E0-145-153-D

Audi Power Steering Pump Part Number: 8E0-145-153-H

$748.62 MSRP: $967.83You Save: $219.21 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

- Replaces: 8E0-145-153

Audi Power Steering Pump Part Number: 7L8-422-153-F

$735.74 MSRP: $951.18You Save: $215.44 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

Audi Power Steering Pump Part Number: 4F0-145-155-H

$925.45 MSRP: $1196.44You Save: $270.99 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

Audi Power Steering Pump Part Number: 4E0-145-155-N

$992.46 MSRP: $1283.08You Save: $290.62 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

- Replaces: 7L8-422-154-A, 7L8-422-154-E

Audi Power Steering Pump Part Number: 8E0-145-155-P

$901.41 MSRP: $1165.37You Save: $263.96 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump; Power Steering Pump

Audi Power Steering Pump Part Number: 074-145-167-C

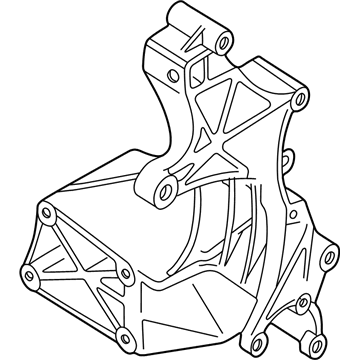

Product Specifications- Other Name: Bracket; Power Steering Pump

- Replaces: 074-145-167-A

| Page 1 of 3 |Next >

1-20 of 60 Results

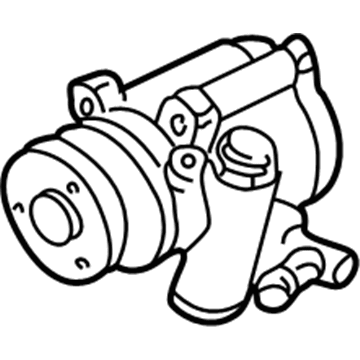

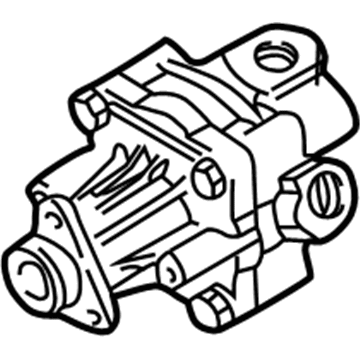

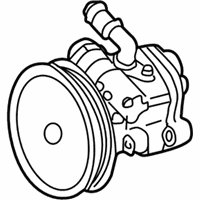

Audi Power Steering Pump

The steering system of a car is made easier by the Audi power steering pump, which pumps fluid to it for effortless steering by the driver. The power steering pump, however, like other vehicle parts, can wear out after prolonged usage. In addition, such factors as rust and corrosion due to environmental elements and operating your vehicle with an inadequate supply of power steering fluid may also interfere with its performance. Consequently, frequent replacement or repair of the power steering pumps becomes inevitable for a car owner.

It is better to choose OEM parts when it comes to the time for fixing them. Why? Because they fit perfectly well and ensure safety. For people who prefer doing their maintenance, the genuine Audi Power Steering Pump is quite perfect. At AudiPartsGiant.com, we specialize in genuine Audi Power Steering Pumps only. Also, we offer an extensive online catalog with many categories, ample stock, and secure shopping. The Audi Power Steering Pump is shipped directly from authorized Audi dealers at competitive prices. So trust us, and we will give you nothing but superior service. Depend on us for all your genuine parts needs, and then we will keep your automobile moving smoothly.

Audi Power Steering Pump Parts and Q&A

- Q: What are the steps required for refitting the power steering pump and associated components on Audi 100?A:New fluid pipe sealing rings will be required on refitting. On models equipped with self-levelling rear suspension, the power steering pump also operates the hydraulic self-levelling system, and a new suspension system hydraulic hose union bolt will be required on refitting. Firmly apply the handbrake, jack up the front of the vehicle, and support it on axle stands. Remove the retaining screws and fasteners to take off the undercover from beneath the engine/transmission unit. Loosen the bolts securing the pulley(s) to the power steering pump and release the auxiliary drivebelt(s) from the power steering pump pulley(s). Use brake hose clamps to clamp both the supply and return hoses near the power steering fluid reservoir to minimize fluid loss during subsequent operations. Unscrew the retaining bolts and remove the pulley(s) from the pump, then wipe clean the area around the power steering pump fluid pipe unions. On 4-cylinder engines, make alignment marks between the pipe unions and pump to avoid confusion on refitting, unscrew the union bolts, and disconnect fluid pipes from the pump while being prepared for fluid spillage; position a suitable container beneath the pipes while unscrewing the union bolts. Disconnect the pipes and recover the sealing rings, discarding the old ones as new ones must be used on refitting. Plug the pipe ends and steering pump orifices to minimize fluid leakage and keep dirt out of the hydraulic system. On models with self-levelling suspension, the suspension system pipe union bolt should be renewed whenever it is removed. On 5-cylinder engines, slacken the retaining clip and disconnect the fluid supply hose from the pump, then slacken the union bolt(s) and disconnect the outlet pipe(s), being prepared for some fluid spillage and plugging the hose/pipe ends and pump unions to minimize fluid loss and prevent dirt entry into the system. Discard the outlet pipe sealing rings as new ones must be used on refitting. Slacken and remove the pump mounting bolts and withdraw the pump from its bracket. If the power steering pump is faulty, it must be renewed as it is a sealed unit and cannot be overhauled. To refit, manoeuvre the pump into position and refit its mounting bolts. On models with a spring-loaded auxiliary drivebelt tensioner, tighten the mounting bolts to the specified torque, and on models where the drivebelt tension is adjusted by pivoting the pump, tighten the bolts lightly only at this stage. Fit a new sealing ring to each side of the hydraulic pipe end fittings, reconnect the pipe(s) to the pump, and screw in the union bolt(s), ensuring the pipe(s) is/are correctly routed before tightening the union bolt(s) to the specified torque. On 5-cylinder engines, reconnect the supply hose to the pump and secure it with the retaining clip, then remove the brake hose clamps used to minimize fluid loss. Refit the pulley(s) to the pump, screw in the retaining bolts, and tighten them to the specified torque. Refit the auxiliary drivebelt(s) and tension it, tightening the pump mounting bolts to the specified torque if not already done. Finally, refit the undercover, ensuring it is securely held by all its retaining screws and fasteners, and on completion, bleed the hydraulic system.

- Q: How to disconnect and replace the power steering pump on Audi A4?A:Unplug the cable on the negative end of the battery and take off the drivebelt. In the case of four-cylinder models, lift the front of the vehicle and rest it on the jackstands, then take away the splash shield under the vehicle, the front bumper, and relocate the radiator support panel to the service position. Disconnect the power steering pump drivebelt, clamp both supply and return hoses around the power steering fluid reservoir to reduce the loss of fluid and wipe the area around the power steering pressure and return line fittings. Do this by unscrewing the banjo bolt and unscrewing the pressure line on the pump, and by placing a container under the pipe when doing it, in case of fluid spillage, and unscrewing the filling bolt. Un-plug the line and retrieve the sealing washers and dispose them as new ones would be required to be used during reassembly. Insert the end of the line and the orifice of the steering pump in order to reduce the fluid leakage and keep dirt out of the hydraulic system. Unscrew the clamp and unplug the hose of the fluid supply on the back of the power steering pump, and plug the end of the hose and cover the pump fluid port to avoid contamination. Unscrew the pump mounting fasteners, and dismount the pump off its bracket, observing that in some instances the mounting fasteners and the pulley may have to be detached off of the pump. In case the power steering pump is defective, it should be replaced since it is a closed system which cannot be serviced. In case new pump is to be installed, before it is started it should be primed with fluid to provide sufficient lubrication during the initial stages of operation otherwise it may run noisily and may fail within short time. In order to start the pump, add the required grade of hydraulic fluid in the fluid supply port of the pump and at the same time rotate the pump pulley until fluid is released to the pressure port. Install pump and screw in the mounting bolts and tighten the bolts to the torque. Install the pressure line to the pump using new sealing washers, and make sure that the line is correctly laid, and that the banjo bolt is tightened to the torque. Reconnect the supply hose up to the pump and lock up the retaining clip and then take off the hose clamps applied to ensure minimal loss of fluid. Attach the steering pump pulley (optional) will be removed, the power steering pump drivebelt, radiator support panel, the front bumper, and the bottom splash shield. Re-attach the negative battery cable, fill the hydraulic and bleed the hydraulic system. To work on V6 models, lift up the engine cover on the top, unscrew the pulley off the pump with a strap wrench so that it does not rotate, and unscrew the rear mount of the power steering pump with a long extension and socket above. Unscrew the banjo bolt and unattach the pressure line to the pump, expecting the spillage of fluid but take back the sealing washers, which should be disposed of and new ones got when assembling. Insert the end of the line and the orifice of the steering pump in order to reduce the fluid leakage and keep dirt out of the hydraulic system. Unclamp and unlink the hose supplying the fluid to the pump and seal the end of the hose and cover the pump fluid port to avoid contamination. Unbind the fasteners of the pump bracket mounting and loosen the pump and the bracket with the engine, and unattach the pump with the mounting bracket, by removing the fasteners. In case the power steering pump is defective, it should be replaced since it is a closed system which cannot be serviced. In case new pump is to be installed, before it is started it should be primed with fluid to provide sufficient lubrication during the initial stages of operation otherwise it may run noisily and may fail within short time. To start the pump, fill the pump by pouring the predetermined grade of power steering fluid to the fluid supply inlet on the pump and at the same time move the pump pulley until the fluid comes out of the pressure inlet. Install the mounting fasteners, position the pump and the bracket and tighten them to the torque. Install the pressure line to the pump using new sealing washers, and make sure that the line is correctly laid, and that the banjo bolt is tightened to the torque. Reconnect the supply hose up to the pump and lock up the retaining clip and then take off the hose clamps applied to ensure minimal loss of fluid. Connect the pulley with the bolts to the torque, put in place the ignition coil assembly, and the top cover of the engine. Connect the negative battery cable again, refill the power steering fluid and bleed the system.

Related Audi Parts

Browse by Model

100 Power Steering Pump 100 Quattro Power Steering Pump 200 Power Steering Pump 200 Quattro Power Steering Pump 4000 Power Steering Pump 4000 Quattro Power Steering Pump 5000 Power Steering Pump 5000 Quattro Power Steering Pump 80 Power Steering Pump 80 Quattro Power Steering Pump 90 Power Steering Pump 90 Quattro Power Steering Pump A4 Power Steering Pump A4 Quattro Power Steering Pump A5 Power Steering Pump A5 Quattro Power Steering Pump A6 Power Steering Pump A6 Quattro Power Steering Pump A8 Power Steering Pump A8 Quattro Power Steering Pump Allroad Quattro Power Steering Pump Cabriolet Power Steering Pump Coupe Power Steering Pump Coupe Quattro Power Steering Pump Q5 Power Steering Pump Q7 Power Steering Pump Quattro Power Steering Pump R8 Power Steering Pump RS4 Power Steering Pump S4 Power Steering Pump S5 Power Steering Pump S6 Power Steering Pump S8 Power Steering Pump TT Power Steering Pump TT Quattro Power Steering Pump V8 Quattro Power Steering Pump