×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

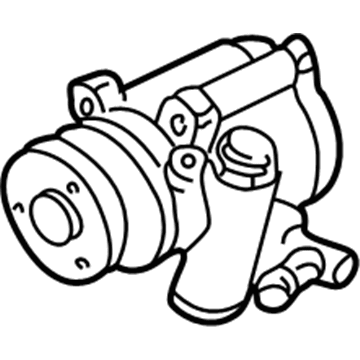

Genuine Audi 90 Power Steering Pump

Power Steering Pump Unit- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Power Steering Pumps found

Audi 90 Power Steering Pump Part Number: 026-145-155-BX

$327.33 MSRP: $458.33You Save: $131.00 (29%)Ships in 1-2 Business DaysAudi 90 Power Steering Pump Part Number: 050-145-155-CX

$340.01 MSRP: $474.00You Save: $133.99 (29%)Ships in 1-2 Business DaysAudi 90 Power Steering Pump Part Number: 034-145-165-X

$450.66 MSRP: $630.00You Save: $179.34 (29%)Ships in 1-2 Business DaysAudi 90 Power Steering Pump Part Number: 054-145-165-GX

$504.92 MSRP: $707.00You Save: $202.08 (29%)Ships in 1-2 Business DaysAudi 90 Power Steering Pump Part Number: 034-145-159-L

$657.48 MSRP: $850.00You Save: $192.52 (23%)Ships in 1-2 Business DaysAudi 90 Power Steering Pump Part Number: 8G0-145-165-X

$1274.74 MSRP: $1527.14You Save: $252.40 (17%)Ships in 1-2 Business Days

Audi 90 Power Steering Pump

Choose original equipment manufacturer Power Steering Pump for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Power Steering Pump at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi 90 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your 90 needs now.

Audi 90 Power Steering Pump Parts and Q&A

- Q: How to overhaul a Power Steering Pump on a radiator cooling fan on Audi 90?A:Start by unbolstering and taking out the radiator cooling fan cowling where necessary. The second step is to loosen the pump adjustment, pivot and mounting bolts, swivel the pump towards the engine and loosen the drivesbelt between the pulley. A container of appropriate size should be placed under the pump to receive any fluid that may escape. Install the hose clamps to the pressure and reconnect flexible hoses, unscrew the bolts of the union to release the hoses, then unscrew the bolts of the hose support bracket (possibly with a bolt) and recover the sealing washers. Take out the pivot and the mounting bolts and pull out the pump in the engine. Spare parts should also be ready before pump overhaul and it is also important to put the cost into consideration towards a new unit, or it would be more profitable to buy the new unit. Do the job in a clean place so that dust and dirt do not destroy the internal parts. Wipe down the outside of the pump then undo the studs and take off the rear cover but make sure to label both covers with respect to one another and replace the O-ring seal. Take out the spring and limiting valve, peer out the securing element, then the seal support, seal and channel plate. When removing an arrow pay attention to the arrow on the outside of the stator. Take out the circlip on the shaft and take out the rotor making sure you keep the vanes in place to identify. Take the shaft out of the rear cover and with a screwdriver, prise out the oil seal. Wipe every part and note the wear and any other damage, turning the bearing, to test it. Get a repair kit that has seals, seal support and circlip. Install the pump the same way that it was removed, with the new parts, being careful to moist the oil seal into the system hydraulic fluid, and then squeeze it firmly into the housing with a block of wood. Insert the securing element by pushing on the casing hole, making sure that the arrow of the stator is furthest. Install the same circlip which was used in the repair kit, and fitting the halves of the casing properly, in the position of the oil holes, use locking fluid upon the threads of the casing studs, before fitting and screwing them in. Refitting is the opposite of de-fitting, but before doing this, we recommend emptying the pump of all air by pumping hydraulic fluid therewith, and then flush the air out of the pump by hand rotation of the pulley. Install the new sealing washers and tighten the union bolts as per the required torque, adjust the drivebelt and refill the system with fluid.