×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi A3 Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Cylinder Heads found

Audi A3 Cylinder Head Part Number: 06K-103-063-AN

$2448.41 MSRP: $2939.27You Save: $490.86 (17%)Ships in 1-2 Business DaysAudi A3 Cylinder Head Part Number: 06K-103-063-BJ

$1797.19 MSRP: $2157.49You Save: $360.30 (17%)Ships in 1-2 Business DaysAudi A3 Cylinder Head Part Number: 06H-103-064-AE

$1308.99 MSRP: $1571.41You Save: $262.42 (17%)Ships in 1-2 Business DaysAudi A3 Cylinder Head Part Number: 06H-103-064-AF

$1790.94 MSRP: $2149.99You Save: $359.05 (17%)Ships in 1-2 Business DaysAudi A3 Cylinder Head Part Number: 06K-103-063-AL

$4877.81 MSRP: $5855.69You Save: $977.88 (17%)Ships in 1-2 Business DaysAudi A3 Cylinder Head Part Number: 06F-103-265-BX

$2860.36 MSRP: $3403.55You Save: $543.19 (16%)Ships in 1-2 Business DaysAudi A3 Cylinder Head Part Number: 03L-103-265-X

$1776.06 MSRP: $2132.13You Save: $356.07 (17%)Ships in 1-2 Business Days

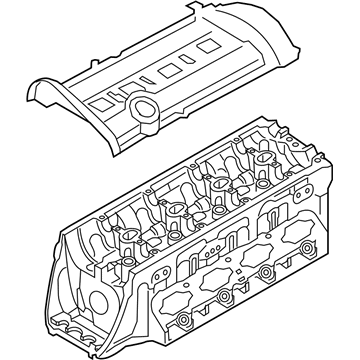

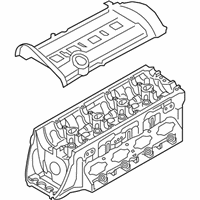

Audi A3 Cylinder Head

Audi A3 Cylinder Head is the designed roof of the combustion chamber, which allows the engine to breathe and holds the burning mixture tightly to produce a powerful and dependable engine. This Cylinder Head, positioned above the cylinders, has the spark plugs, intake and exhaust openings, coolant circulation, and the valvetrain, which directs fresh air-fuel in and exhaust out with minimal restriction through the Audi engine to enable it to make responsive horsepower. Throughout the model years, Audi initially applied robust cast-iron castings and later moved to lightweight aluminum castings. The iron style is durable but heavier, whereas the aluminum Cylinder Head has less mass to provide a better power-to-weight ratio, radiates less, and can even sustain higher compression with reduced detonation, which was adopted in subsequent versions of the A3. However, both designs incorporate torque-to-yield head bolts that deform once to create an even clamping force and assist the head gasket in withstanding wild combustion pressures, which occur in every Audi turbo four. In case of defects, symptoms are misfires from burnt valves, gradual effects from worn guides or springs, or messy leakages in case of warping or cracking that allows coolant to mix with oil. A bursting gasket can also cause compression to escape between cylinders or may push coolant into the chamber, resulting in overheating, thus Audi states new bolts and tightening accuracy are necessary whenever the Cylinder Head is reinstalled.

Choose original equipment manufacturer Cylinder Head for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Cylinder Head at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A3 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A3 needs now.

Audi A3 Cylinder Head Parts and Q&A

- Q: What are the steps involved in removing and refitting a cylinder head for Diesel engines on Audi A3?A:Removal of the cylinder head should be done when the engine is cold and new cylinder head bolts must be installed and a gasket fitted when refitting together with appropriate studs to ensure the cylinder head is correctly placed. Start with turning off the ignition and withdrawal of the key, empty out the cooling system and engine oil. To gain better access to the DOHC engines, take out the battery. The second step is to remove the cover on the plenum chamber and the panel on the back of the engine compartment. Disassemble the air filter, air mass meter and the related ducts, unconnect the fuel supply and return lines and remove the coolant hoses at the cylinder head. Siphoning of fuel of the tandem pump is also recommended. Take out the fuel filter, front exhaust pipe, support of the turbocharger, oil back line, and oil supply line, then the camshaft cover, and Timing Belt. Make sure the engine is properly supported in case the engine mounting right hand is eased off, remove the camshaft sprocket and timing Belt Tensioner. Unscrew all the bolts attaching the rear timing belt cover, take off camshaft position sensor and all electrical wiring, vacuum and coolant hoses. In the case of DOHC engines, loosen the pump injector rocker arm shaft with unbolts, loosen the retaining bolts of the rocker shaft slowly and remove them. Unscrew the cylinder head bolts on the outside, in a multi-splined tool, ensuring that nothing is attached to them, then lift the cylinder head of the engine block. Take out the gasket of the block and store it with dowels as an identification. Check the old gasket markings to identify the type required replacing it and in case new pistons have been used then measure the projection of the piston crowns at TDC to find the necessary gasket thickness required. Wipe the copulating surfaces of the cylinder head and block, making sure no matter does not get into the pipes of the oil and water, and also to see whether there is any damage that needs to be repaired. Rotate the crankshaft to align the pistons with the same height to prevent hitting the valves in refitting. Install guide studs, fit the new gasket and get the head in place. Install the new cylinder head bolts and apply them in order of listed torque in stages and lastly angle-tighten. Once tightened, reposition the camshaft and re-fit any lifting tackle where necessary. The refitting process is the reverse of the removal process whereby, in order to refit the injector rocker shaft, camshaft cover, and also reconnect the turbocharger oil.

- Q: What tool is required for the operation involving valve spring compression on the Cylinder Head on Audi A3?A:A valve spring compressor tool will be required for this operation. For SOHC petrol engines, with the cylinder head removed, begin by removing the inlet and exhaust manifolds. Next, take out the camshaft and hydraulic tappets or roller rocker fingers. If desired, unbolt the coolant housing from the rear of the cylinder head and recover the seal. If not already done, remove the camshaft position sensor. Unscrew the securing nut, recover the washer, and remove the timing belt tensioner pulley from the stud on the cylinder head. Unbolt any remaining auxiliary brackets or engine lifting brackets from the cylinder head as necessary, noting their locations for refitting. Turn the cylinder head over and rest it on one side. Using a valve spring compressor, compress each valve spring in turn until the split collets can be removed. Release the compressor and lift off the spring cap and spring. If the spring cap refuses to free, gently tap the top of the tool directly over the spring cap with a light hammer to free the retainer. Carefully extract the valve stem oil seal from the top of the valve guide using pliers or a removal tool. Withdraw the valve from the gasket side of the cylinder head. It is essential to store each valve together with its collets, cap, spring, and spring seat, keeping them in their correct sequences unless they are so badly worn that they need to be renewed. For DOHC petrol engines, with the cylinder head removed, remove the inlet and exhaust manifolds, unbolt any remaining auxiliary brackets or engine lifting brackets from the cylinder head as necessary, noting their locations for refitting, and ensure that the valves are identified as inlet and exhaust, as well as numbered when labeling the valve components. For diesel engines, with the cylinder head removed, remove the inlet and exhaust manifolds (and turbocharger), camshaft, hydraulic tappets, glow plugs, and fuel injectors. Unscrew the nut and remove the timing belt tensioner pulley from the stud on the timing belt end of the cylinder head, and unbolt any remaining auxiliary brackets or engine lifting brackets from the cylinder head as necessary, noting their locations for refitting. Proceed with the operation.