×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi A3 Belt Tensioner

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Belt Tensioners found

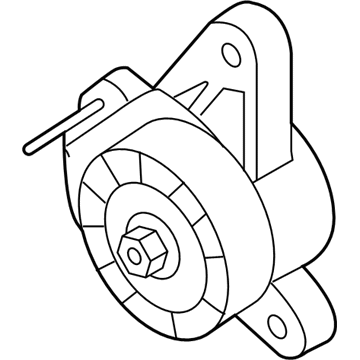

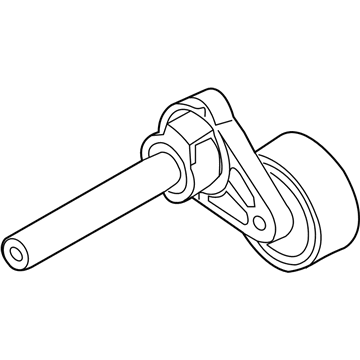

Audi A3 Serpentine Tensioner Part Number: 06F-903-315

$109.47 MSRP: $153.31You Save: $43.84 (29%)Ships in 1-2 Business DaysAudi A3 Serpentine Tensioner Part Number: 038-903-315-AN

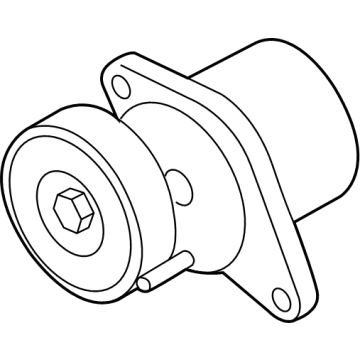

$122.56 MSRP: $171.64You Save: $49.08 (29%)Ships in 1-2 Business DaysAudi A3 Belt Tensioner Part Number: 04L-903-315-K

$122.56 MSRP: $171.64You Save: $49.08 (29%)Ships in 1-2 Business DaysAudi A3 Serpentine Tensioner Part Number: 06Q-903-133-E

$128.51 MSRP: $179.98You Save: $51.47 (29%)Ships in 1-2 Business DaysAudi A3 Serpentine Tensioner Part Number: 06J-903-133-D

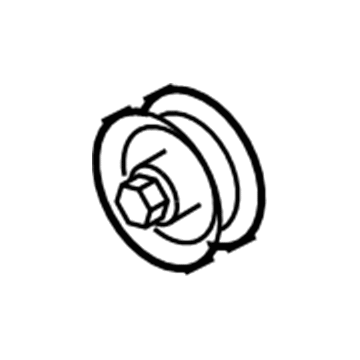

$136.84 MSRP: $191.65You Save: $54.81 (29%)Ships in 1-2 Business DaysAudi A3 Tensioner Pulley Part Number: 06D-109-243-C

$173.73 MSRP: $243.31You Save: $69.58 (29%)Ships in 1-2 Business DaysAudi A3 Tensioner Part Number: 06K-109-467-AG

$94.01 MSRP: $131.66You Save: $37.65 (29%)Ships in 1-2 Business DaysAudi A3 Chain Tensioner Part Number: 06K-109-467-P

$92.81 MSRP: $129.99You Save: $37.18 (29%)Ships in 1-2 Business DaysAudi A3 Tensioner Part Number: 06H-109-467-AE

$104.71 MSRP: $146.64You Save: $41.93 (29%)Ships in 1-2 Business DaysAudi A3 Chain Tensioner Part Number: 06F-109-217-A

$198.72 MSRP: $278.31You Save: $79.59 (29%)Ships in 1-2 Business Days

Audi A3 Belt Tensioner

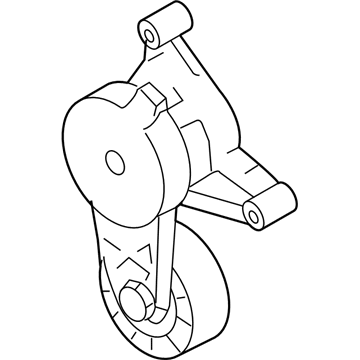

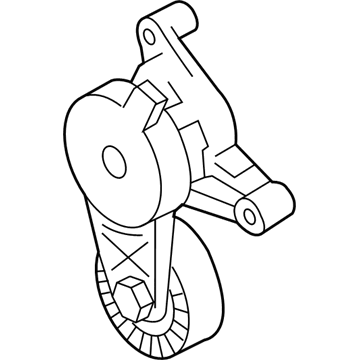

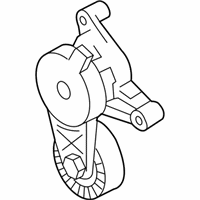

The Audi A3 Belt Tensioner is applied to ensure the serpentine drive belt is tight in order to transmit engine power to essentials without slipping and squeaking. The Belt Tensioner is attached to a spring-loaded arm or an adjustable pivot and applies the precise amount of force that the belt requires as it travels around the alternator, water pump, power steering pump and air conditioning compressor. Its key components include a grooved pulley that serves to guide the belt, a strong arm that enables movement, a coil spring to provide constant pressure and a solid base to help anchor it. Most Audi models are in automatic mode, with an internal spring self-regulating tension to ensure longer life of the belt and bearings, whereas the earlier manually adjustable models needed periodic adjustments, and the automatic style does away with this adjustment routine by responding instantly to the stretch of the belt or vibration in the engine. Some indications of a worn Belt Tensioner are squeals on startup, grinding from worn bearings, ragged edges of the belt, rust that is visible between arm and base or a broken housing. In case of component weakness, parts driven by the belt can slow down or shut down and can overheat or drain batteries. Regular glances at the visage of the Audi engine bay may indicate coarse spinning of the pulley or slack in the arm that can assist owners of the A3 in changing a failing Belt Tensioner before part retinue is undermined. This is a minor but important gadget as it is concerned with the reliability of Audi and therefore, handling the Audi drive belt system with reverence will help ensure smooth motoring.

Choose original equipment manufacturer Belt Tensioner for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Belt Tensioner at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A3 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A3 needs now.

Audi A3 Belt Tensioner Parts and Q&A

- Q: How to remove and reinstall the timing belt tensioner, idler pulleys, crankshaft sprocket, camshaft sprocket, and camshaft hub for Diesel engines on Audi A3?A:Removal of Timing Belt tensioner To remove timing belt tensioner, remove timing belt, unscrew the tensioner nut then remove tensioner unit. During re-installation, the lug on the tensioner backplate should be inserted in the cut-out of the rear timing belt cover first, then the tensioner nut is re-installed. Then refit and tension the timing belt making sure that the tensioner backplate is firmly attached into the cylinder head hole. In the case of the idler pulleys, undo the timing belt, undo the securing bolt or nut and pull out the pulley. Re-fit the pulley and fit the securing bolt/nut to its correct torque, loosening the bolt where necessary and refitting and tightening the timing belt. In the case of the crankshaft sprocket, a new securing bolt is needed during re-fitting. Begin by unbolstering the timing belt, and then loosen the sprocket securing bolt without allowing the crankshaft to turn, and with an appropriate tool to hold on to the sprocket. Unscrew the bolt then slide the sprocket off, being careful of the orientation of the raised boss. To refitting, place the sprocket on the crankshaft correctly, then install a new securing bolt, counter hold the sprocket, and screw a bolt into the sprocker two times to the required torque and then refit the timing belt. In the case of the camshaft sprocket, strip off the timing belt, undo the three retaining bolts and strip off the sprocket. They need to be fitted into position, the sprocket should be turned properly, the tack bolts be inserted and clamped to start with. In case the crankshaft had been rotated, then turn it clockwise to TDC and then refit and tension the timing belt. In the case of the camshaft hub, attach a special tool to ensure that the hub does not rotate and loosen the central retaining bolt one or two turns. Tighten it with a three legged puller in an even manner until the hub is clear of the camshaft taper. Before fitting the camshaft sprocket, clean and dry the camshaft taper and the hub center, align the hub with the keyway, position it, and screw in the center bolt to the required torque and then refit. The coolant pump sprocket is connected with the coolant pump.