×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine 2016 Audi A3 Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Cylinder Head found

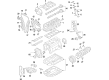

2016 Audi A3 Cylinder Head Part Number: 06K-103-063-AL

$4877.81 MSRP: $5855.69You Save: $977.88 (17%)Ships in 1-2 Business DaysProduct Specifications- Item Weight: 69.90 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 06K-103-063-AL

- Warranty: This genuine part is guaranteed by Audi's factory warranty.

2016 Audi A3 Cylinder Head Parts and Q&A

- Q: How to safely remove and replace a cylinder head for 2.0 litre DOHC petrol engines on 2016 Audi A3?A: Before starting work, switch off the ignition and all electrical consumers, then remove the ignition key. Apply the handbrake, jack up the front of the vehicle, and support it on axle stands. Remove the engine top cover by pulling it upwards from its fasteners. If needed, remove the plenum chamber bulkhead at the rear of the engine compartment for easier access. Drain the cooling system, then unscrew the nuts securing the front exhaust pipe to the exhaust manifold, unbolt the exhaust mounting from the crossmember, and support the exhaust on an axle stand, ensuring not to bend the exhaust pipe flexible joint more than 10°. Unbolt and remove the exhaust manifold supports, then take out the air filter housing and inlet hoses. Disconnect the coolant elbow from the left-hand end of the cylinder head and remove the inlet manifold. Disconnect all electrical connectors from the cylinder head, including the injector loom connectors, oil pressure switch plug, and the electrically-controlled thermostat plug, while releasing the wiring harness from the small coolant pipe on the left-hand side of the engine. For non-turbo models, disconnect the coolant hoses from the throttle valve control module, remove the EGR pipe if applicable, and disconnect the coolant hoses. Remove the auxiliary drivebelt, timing belt, and camshaft cover. Ensure all relevant electrical connectors and coolant hoses are disconnected, plugging or covering any openings to prevent fluid spillage and contamination. Unscrew the M10 Ribe cylinder head bolts in reverse order to the tightening sequence, discarding the bolts as new ones must be fitted. With assistance, lift the cylinder head from the block along with the exhaust manifold, tapping it free with a wooden mallet if necessary, and remove the cylinder head gasket from the block. If needed, remove the exhaust manifold from the cylinder head. Clean the contact faces of the cylinder head and block thoroughly, ensuring no oil or coolant remains in the bolt holes. If the exhaust manifold was removed, refit it to the cylinder head with a new gasket. Place a new gasket on the block with the part number facing upwards and ensure the location dowels are in position. Rotate the crankshaft a quarter of a turn anti-clockwise to prevent piston-to-valve contact, then carefully lower the head onto the block, ensuring it engages the location dowels correctly without using any jointing compound. Insert the new cylinder head bolts and hand-tighten them, then tighten all bolts to the specified Stage 1 torque. Angle-tighten the bolts in the same sequence to the specified Stage 2 and Stage 3 angles. Rotate the crankshaft a quarter of a turn clockwise back to TDC on cylinders 1 and 4, then refit the camshaft cover. The remainder of refitting involves reversing the removal steps, ensuring all electrical connectors are reconnected and harnesses are correctly routed, all coolant hoses are reconnected with retaining clips in their original positions, applying thread-locking compound to the tensioner roller mounting plate bolts, renewing any weak or corroded coolant hose clips, and finally refilling the cooling system with a new antifreeze mixture. If engine oil contamination with coolant is suspected, change the oil and filter.