×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

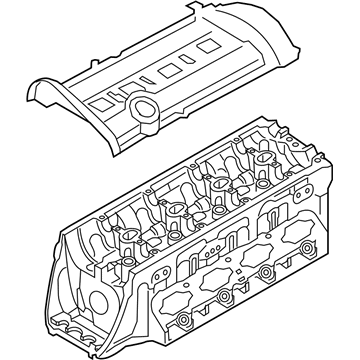

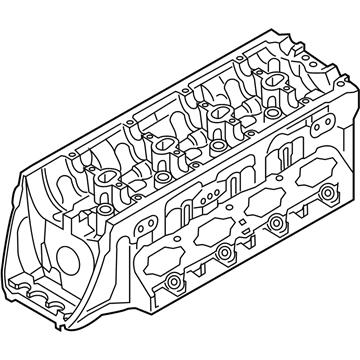

Genuine Audi Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

129 Cylinder Heads found

Audi Cylinder Head Part Number: 06M-103-062-AK

$2008.11 MSRP: $2410.70You Save: $402.59 (17%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

- Replaced by: 06M-103-062-CA

- Replaces: 06M-103-062-AM, 06M-103-062-BB, 06M-103-062-P, 06M-103-062-K

Audi Cylinder Head Part Number: 06K-103-264-E

$1630.29 MSRP: $1957.13You Save: $326.84 (17%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Head

- Replaces: 06K-103-063-AE

Audi Cylinder Head Part Number: 06M-103-061-AK

$2008.11 MSRP: $2410.70You Save: $402.59 (17%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

- Replaced by: 06M-103-061-CA

- Replaces: 06M-103-061-AM, 06M-103-061-BB, 06M-103-061-P, 06M-103-061-K

Audi Cylinder Head Part Number: 06K-103-063-AN

$2448.41 MSRP: $2939.27You Save: $490.86 (17%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: 06K-103-264-D

Audi Cylinder Head Part Number: 06H-103-064-N

$2062.27 MSRP: $2475.72You Save: $413.45 (17%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 06K-103-063-BJ

$1797.19 MSRP: $2157.49You Save: $360.30 (17%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 06H-103-064-AC

$2436.51 MSRP: $2924.99You Save: $488.48 (17%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: 06H-103-264-A

- Replaces: 06H-103-064-L

Audi Cylinder Head Part Number: 06H-103-063-L

$1933.20 MSRP: $2166.05You Save: $232.85 (11%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 026-103-265-QX

$788.91 MSRP: $1019.92You Save: $231.01 (23%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 026-103-351-S

Audi Cylinder Head Part Number: 034-103-351-G

$846.98 MSRP: $1095.00You Save: $248.02 (23%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 078-103-351-B

$1090.04 MSRP: $1409.23You Save: $319.19 (23%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 06E-103-065-B

$1147.04 MSRP: $1377.00You Save: $229.96 (17%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 06E-103-065-C

$1416.10 MSRP: $1700.00You Save: $283.90 (17%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 06E-103-066-C

$1416.10 MSRP: $1700.00You Save: $283.90 (17%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 06E-103-065-BX

$1147.04 MSRP: $1377.00You Save: $229.96 (17%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: 06E-103-065-B

Audi Cylinder Head Part Number: 06E-103-904-GX

$1405.46 MSRP: $1677.14You Save: $271.68 (17%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 06E-103-903-GX

$1406.65 MSRP: $1678.57You Save: $271.92 (17%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 06E-103-066-BX

$1495.01 MSRP: $1782.13You Save: $287.12 (17%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 06E-103-066-B

Audi Cylinder Head Part Number: 06E-103-903-JX

$1438.78 MSRP: $1717.14You Save: $278.36 (17%)Ships in 1-2 Business DaysAudi Cylinder Head Part Number: 078-103-265-JX

$1443.54 MSRP: $1722.86You Save: $279.32 (17%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 078-103-067-BH

| Page 1 of 7 |Next >

1-20 of 129 Results

Audi Cylinder Head

The mechanics consider the cylinder head very important. It is found on top of the engine block. It closes the cylinder with pistons by using gaskets and safeguards other parts that are fragile and deserve care in an engine. It is the role that an Audi cylinder head has to play in maintaining vacuum conditions within the engine, thereby preventing wear and tear on engine parts. Nonetheless, if there are leaks, cracks, or any other mechanical issues with this part of the car, it can cause the internal combustion engine to malfunction. Do not wait too long before acting on any impending problem as far as this matter is concerned. If you perceive a problem with your motor's cylinder head, stop driving immediately, for it may need replacement.

It is better to choose OEM parts when it comes to the time for fixing them. Why? Because they fit perfectly well and ensure safety. For people who prefer doing their maintenance, the genuine Audi Cylinder Head is quite perfect. At AudiPartsGiant.com, we specialize in genuine Audi Cylinder Heads only. Also, we offer an extensive online catalog with many categories, ample stock, and secure shopping. The Audi Cylinder Head is shipped directly from authorized Audi dealers at competitive prices. So trust us, and we will give you nothing but superior service. Depend on us for all your genuine parts needs, and then we will keep your automobile moving smoothly.

Audi Cylinder Head Parts and Q&A

- Q: How should the cylinder head be removed and refitted with the engine cold for 1.6 litre SOHC petrol engines on Audi A3?A:Cylinder head has to be pulled off when the engine is cold and new cylinder head bolts and a gasket should be used when refitting. The first thing is to turn off the ignition and remove the key and then the engine top cover and drain the cooling system. Take out the upper inlet manifold with the clean cloths inserted in the lower manifold port to avoid dust entering the machine. Unscrew the distribution case of the coolant of the left side of the cylinder head, reassembling the O-ring without removing hoses. Unscrew the clip and unplug the breather hose at the rear outlet of the cylinder head and unplug all the wiring, and record their locations. Unbolt the exhaust front part including the catalytic converter and lift it off to the side, and remove the auxiliary drivebelt and timing belt. Disassemble the timed belt inner cover, the camshaft sprocket, and (in models with secondary air injection) disconnect and remove the pipes and pump used. Disassemble the hose and the charcoal canister solenoid valve, remove spark plug HT leads, camshaft position sensor wiring, and the right-angled bracket complete with auxiliary drivebelt tensioner. Hold the engine with a hoist or trolley jack, the pertinent bracket should be attached to the cylinder block. When supporting the engine, remove the camshaft cover and ensure that all the wiring, pipes and hoses are unconnected. Tighten and loosen progressively the cylinder head bolts, then hoist the cylinder head out of the block along with the exhaust manifold and the lower inlet manifold, being careful not to loosen it too much. Loose the gasket on the cylinder head and, when, wished, the exhaust manifold and lower inlet manifold may be removed off the cylinder head. Wipe the mating surfaces of the cylinder head and block using a rag and clean all traces of gasket and carbon, and no debris should be allowed to get into the oil and water passages. Should there be nicks or scratches on the head and block, it should be checked and in case of the suspicion of warpage, a straight-edge should be used to test. Be sure that the holes in the cylinder head bolts are oiled free and rotate the crankshaft so that Nos 1 and 4 pistons are slightly below their bores in order to prevent piston-to-valve contact. Install a new cylinder head gasket with the dowels (with exception of lower inlet manifold) and install exhaust manifold and lower inlet manifold as necessary, with the part number at the top. Insert the cylinder head and install the new bolts, and tighten the bolts in stages until the required torque is reached and then through stages until the required angles are met. Refit the lifting tackle to the right-hand lifting bracket of the engine, hold up the engine, and break the lifting tackle during the cylinder block. Re-fit the timing belt inner cover, camshaft cover, and camshaft sprocket and tighten the timing belt. Install the exhaust front section, secondary air injection pump, and pipes (where removed), coolant distribution housing, and re-attach the hoses. Reassemble the hose of the charcoal canister solenoid valve, the auxiliary drivebelt, spark plug HT leads, the wiring to the camshaft position sensor, the right-angled bracket and the auxiliary drivebelt tensioner. Re-wire all, re-assemble top of inlet manifold, replace cooling system and lastly re-assemble engine top cover.

- Q: What are the steps involved in cylinder head dismantling and overhaul for 4-cylinder petrol engines on Audi 100?A:Both ADR and non-ADR engines have a number of steps that are involved in cylinder head dismantling and overhaul. Start by unscrewing the battery negative lead and de-mounting the undershield of the engine compartment, and jacking the front of the car high as needed. Lift the engine top cover where applicable, then unscrew the nuts and remove the exhaust downpipe until it unconnection with the exhaust manifold, holding it on an axle stand, and retrieving the gasket. The next step involves unscrewing the nuts and bolts to take the exhaust manifold off of the cylinder head which drains the cooling system and coolant out of the engine by disconnecting the small hose that attaches to the thermostat housing. Disconnect different hoses and wires, such as the top hose at the coolant pipe, inlet manifold variable choke valve wiring and the ignition coil. Take away the inlet manifold, timing belt and cylinder head bolts in that order of tightening and lift the cylinder head off the block and the gasket. To refit, clean up the contact faces of the cylinder head and block, put a new gasket on the block and lower the head without going through jointing compound. Install and screw-in the cylinder head bolts and screw-in to the desired torque respectively. Reinstall parts of the timing belt, exhaust manifold and downpipe, clean up all the hoses and wiring by reconnecting them. Lastly, coolant, renew under shield and reconnect battery negative lead and make sure that the engine cover is replaced at the top as well.

Related Audi Parts

Browse by Model

100 Cylinder Head 100 Quattro Cylinder Head 200 Cylinder Head 200 Quattro Cylinder Head 4000 Quattro Cylinder Head 80 Cylinder Head 90 Cylinder Head 90 Quattro Cylinder Head A3 Cylinder Head A3 Quattro Cylinder Head A3 Sportback e-tron Cylinder Head A4 Cylinder Head A4 Quattro Cylinder Head A5 Cylinder Head A5 Quattro Cylinder Head A6 Cylinder Head A6 Quattro Cylinder Head A6 allroad Cylinder Head A7 Quattro Cylinder Head A7 Sportback Cylinder Head A8 Quattro Cylinder Head Allroad Quattro Cylinder Head Cabriolet Cylinder Head Coupe Cylinder Head Q3 Cylinder Head Q3 Quattro Cylinder Head Q5 Cylinder Head Q7 Cylinder Head Q8 Cylinder Head Quattro Cylinder Head R8 Cylinder Head RS3 Cylinder Head RS4 Cylinder Head RS5 Cylinder Head RS7 Cylinder Head S3 Cylinder Head S4 Cylinder Head S5 Cylinder Head S5 Sportback Cylinder Head S6 Cylinder Head S7 Cylinder Head S8 Cylinder Head SQ5 Cylinder Head SQ5 Sportback Cylinder Head TT Cylinder Head TT Quattro Cylinder Head TT RS Quattro Cylinder Head TTS Quattro Cylinder Head V8 Quattro Cylinder Head allroad Cylinder Head