×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

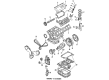

Genuine Audi 100 Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Cylinder Head found

Audi 100 Cylinder Head Part Number: 078-103-351-A

$1077.45 MSRP: $1207.22You Save: $129.77 (11%)Ships in 1-2 Business Days

Audi 100 Cylinder Head

Choose original equipment manufacturer Cylinder Head for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Cylinder Head at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi 100 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your 100 needs now.

Audi 100 Cylinder Head Parts and Q&A

- Q: What are the steps involved in cylinder head dismantling and overhaul for 5-cylinder diesel engines on Audi 100?A:There are various processes that are involved in cylinder head breaking and re-assembling. Start by unhooking the battery negative terminal, emptying the engine top cover and undershield, depleting the engine oil and cooling system and unhooking all the coolant and vacuum hoses to the cylinder head. Then take out the auxiliary drivebelt, tensioner of the timing belt and camshaft sprocket and make sure that the engine is positioned at TDC on cylinder No 1. Disassemble the timing belt covers, camshaft cover and fuel injection pump drivebelt then unbolt the injector fuel supply pipes and disconnect all the electrical wiring involved. Depending on the type of engine, de-turbo and de-exhaust down pipe (where required). Next, dismount the inlet and exhaust manifolds, crankcase ventilation oil separator and brake vacuum pump, and make sure to remove the cylinder head bolts in the proper order, which is beer, butter, and bread. Once the cylinder head has been lifted off, clean the mating surfaces and examine the surfaces looking into possible damage and warping. In case of refitting, it is essential to fit the new head gasket always in the right position, to align the cylinder head by the block with modified bolts and by tightening the bolts to the cylinder head in a sequence and a torque that has been prescribed. Check It Reinstall brakeness Vacuum pump, manifolds, turbocharger, and reconnect all hoses and wiring. Last but not least, fill the cooling system and engine oil back up, re-attach the undershield, reconnect the battery and start the engine with a check of the cylinder head bolts to ensure they are tightened to the correct level in the post-engine-start process.