×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

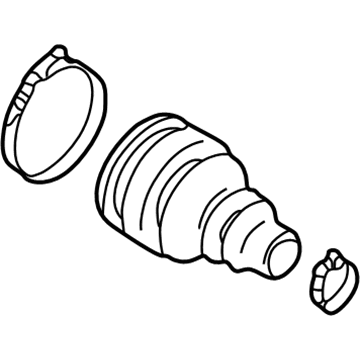

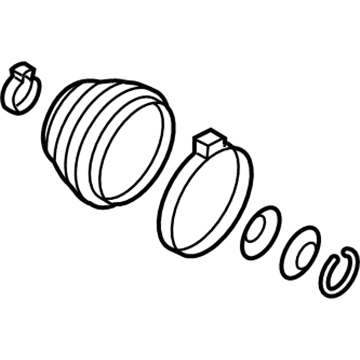

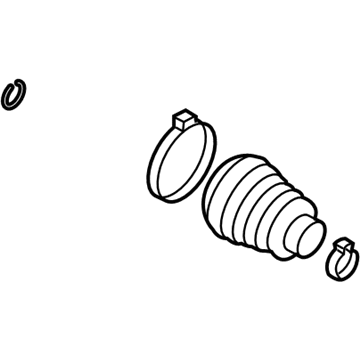

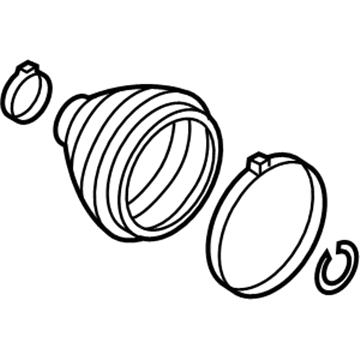

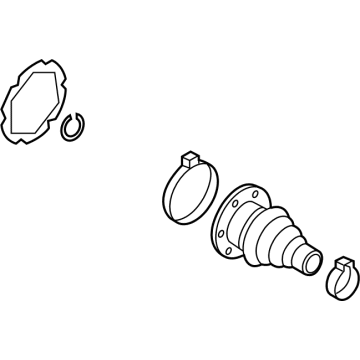

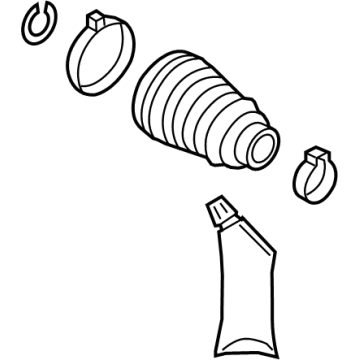

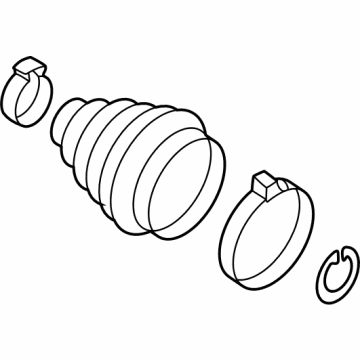

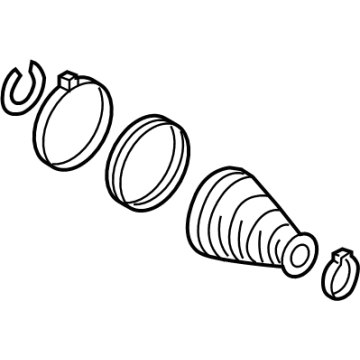

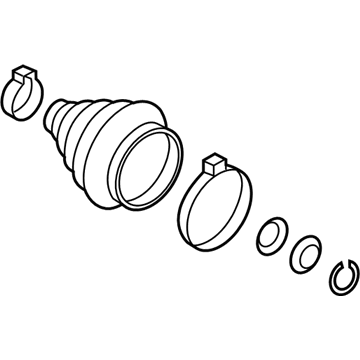

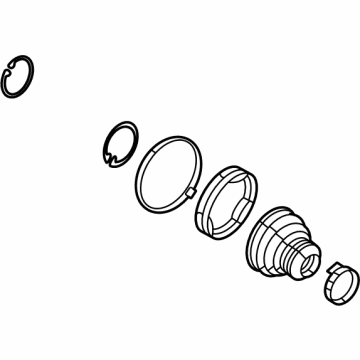

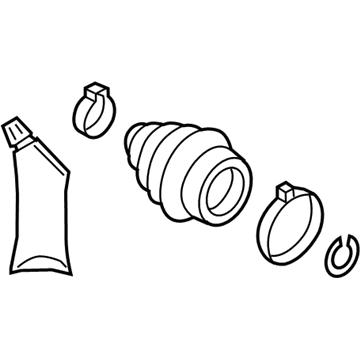

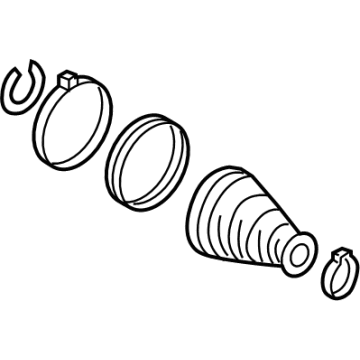

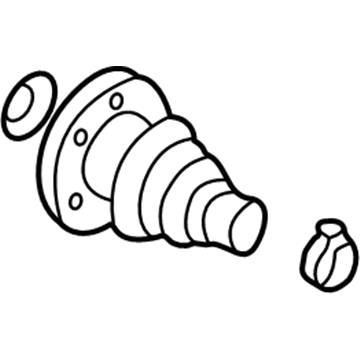

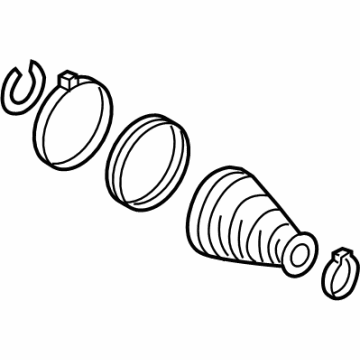

Genuine Audi CV Joint Boot

Constant-Velocity Joint Boot- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

145 CV Joint Boots found

Audi Outer Boot Part Number: 443-498-203-A

$37.51 MSRP: $62.00You Save: $24.49 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Outer Boot

Audi Outer Boot Part Number: 1K0-498-203-A

$12.90 MSRP: $20.64You Save: $7.74 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot

- Position: Outer

- Replaces: 3B0-498-203-E, 1J0-498-203-C

Audi Inner CV Joint Boot Part Number: 3Q0-498-201

$14.19 MSRP: $22.70You Save: $8.51 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Inner CV Joint Boot

- Position: Inner

- Replaces: 3C0-498-201-A

Audi Outer Boot Part Number: 4H0-498-203

$13.00 MSRP: $20.80You Save: $7.80 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot

- Position: Outer

- Replaces: 7P0-498-203, 80A-498-203-A

Audi Inner CV Joint Boot Part Number: V04-017-001-BK

$19.74 MSRP: $31.58You Save: $11.84 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Inner Boot, Inner CV Joint Boot

Audi Inner Boot Part Number: 1K0-498-201-F

$20.00 MSRP: $32.00You Save: $12.00 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot

- Position: Inner

- Replaces: 1K0-498-201-K

Audi Outer CV Joint Boot Part Number: 1EA-598-203-A

$8.90 MSRP: $13.90You Save: $5.00 (36%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Outer Boot, Outer CV Joint Boot

Audi Inner CV Joint Boot Part Number: 1EA-498-201-B

$8.86 MSRP: $13.84You Save: $4.98 (36%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Inner Boot, Inner CV Joint Boot

Audi Outer Boot Part Number: 321-498-203-A

$25.50 MSRP: $40.80You Save: $15.30 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Boot Kit

- Position: Outer

- Replaces: 191-498-203

Audi Outer Boot Part Number: 1K0-498-203-C

$27.25 MSRP: $43.60You Save: $16.35 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot

- Position: Outer

Audi Inner Boot Part Number: 4KE-498-201

$53.59 MSRP: $73.82You Save: $20.23 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Inner Boot

Audi Outer Boot Part Number: 5N0-498-203

$28.13 MSRP: $45.00You Save: $16.87 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Outer Boot

Audi Outer Boot Part Number: 893-498-203-B

$28.31 MSRP: $45.30You Save: $16.99 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot

- Position: Outer

Audi Outer Boot Part Number: 1K0-498-203-F

$12.89 MSRP: $20.62You Save: $7.73 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot

- Position: Outer

Audi Outer Boot Part Number: 431-498-203-C

$31.13 MSRP: $49.80You Save: $18.67 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Outer Boot

Audi Inner Boot Part Number: 760-498-201

$44.03 MSRP: $60.65You Save: $16.62 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Inner Boot

- Replaced by: 760-498-201-B

Audi Inner Boot Part Number: 321-498-201-E

$31.38 MSRP: $50.20You Save: $18.82 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Boot Kit

- Position: Inner

Audi Inner Boot Part Number: 760-498-201-A

$43.56 MSRP: $60.01You Save: $16.45 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot; Inner Boot

Audi Inner Boot Part Number: 191-498-201-D

$34.38 MSRP: $55.00You Save: $20.62 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot

- Position: Inner

Audi Inner Boot Part Number: 8X0-598-201

$38.22 MSRP: $52.65You Save: $14.43 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot

- Position: Inner

| Page 1 of 8 |Next >

1-20 of 145 Results

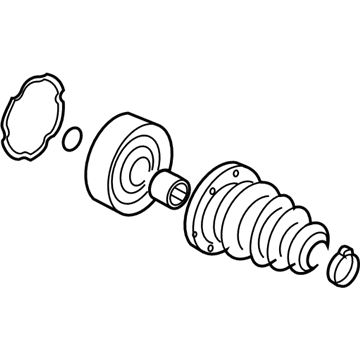

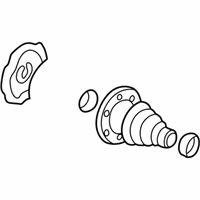

Audi CV Joint Boot

The Audi CV Joint Boot is a very important part of your vehicle. Therefore, it has to be maintained in good condition to avoid performance issues and comfortable driving. And these regular checks and replacements will ultimately save you some big repair costs. It is better to choose OEM parts when it comes to the time for fixing them. Why? Because they fit perfectly well and ensure safety. For people who prefer doing their maintenance, the genuine Audi CV Joint Boot is quite perfect. At AudiPartsGiant.com, we specialize in genuine Audi CV Joint Boots only. Also, we offer an extensive online catalog with many categories, ample stock, and secure shopping. The Audi CV Joint Boot is shipped directly from authorized Audi dealers at competitive prices. So trust us, and we will give you nothing but superior service. Depend on us for all your genuine parts needs, and then we will keep your automobile moving smoothly.

Audi CV Joint Boot Parts and Q&A

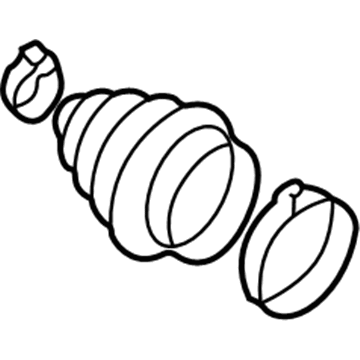

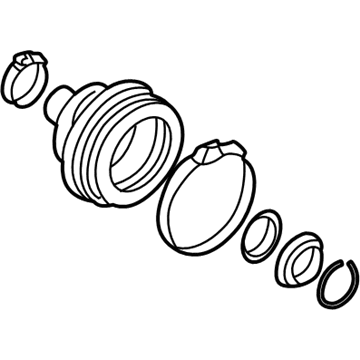

- Q: How to inspect the condition of the outer and inner CV Joint Boot and assess the general condition of the CV joints for Diesel engines on Audi A3?A:Having the car lifted and resting on the stands, turn the roadwheel slowly, checking the condition of the outer constant velocity (CV) joint rubber boot, by opening out the folds by squeeze. Watch for rubber cracking, splitting, or weakening, as this can allow grease to escape and permit water and grit to enter the joint. Also, check the fixing and condition of the retaining clips. Check the state of the CV joint boots as well as the inner joints again. Boots should be renewed in case any damage or deterioration is observed. Meanwhile, examine the overall state of the CV joints by grasping the driveshaft and trying to turn the wheel, and then perform the same check by grasping the inner joint and trying to turn the driveshaft. Any appreciable movement indicates wear in the joints, wear in the splines of the driveshaft, or a loose nut that holds the driveshaft in position.

- Q: Should the CV Joint Boot be inspected periodically to prevent excessive tire wear and handling issues on Audi A4?A:The steering linkage and the suspension parts are to be inspected on a regular basis because the worn and damaged components may cause excessive wear of tires, poor ride quality, handling, and lower fuel economy. Checking shock absorbers requires parking the vehicle on flat floor, and switching off the engine and putting on the parking brake after which tire pressure is checked. To test the vehicle, press on one corner of the vehicle and release it and it ought to stop and go back to the level position in one or two bounces and in the event that it does not, the shock absorber might be defective or old. Check this at the other corners repeatingly and then ensure that the vehicle has been elevated safely on jackstands. Examine the shock absorbers to confirm that the fluid is not leaking and the fluid that is detected should be a result of the shocks after which they should be replaced as a set. Make sure that the shocks are firmly installed, make sure that they are not worn or damaged at the upper mounts, and change them, where necessary. To perform the steering and suspension inspection, visually inspection of all parts should be done to determine whether there is damage, distortion and leaks, especially around the bushings where the control arms connect with the chassis. Wipe out the lower end of the steering knuckle and also have someone to move the wheel in-and-out in monitoring any movement in the balljoint and any movement would show that it required replacement. Check play in the components of the steering system by grabbing each of the front tires and checking them to see whether there is looseness in the steering gear mounts and tie-rod ends. Finally, check the driveaxle boots in case of tears, cracks and loose clamps and they prevent the dirt and damage of the constant velocity joints; any traces of cracks or leaking lubricant require replacement.

Related Audi Parts

Browse by Model

100 CV Joint Boot 100 Quattro CV Joint Boot 200 CV Joint Boot 200 Quattro CV Joint Boot 4000 CV Joint Boot 4000 Quattro CV Joint Boot 5000 CV Joint Boot 5000 Quattro CV Joint Boot 80 CV Joint Boot 80 Quattro CV Joint Boot 90 CV Joint Boot 90 Quattro CV Joint Boot A3 CV Joint Boot A3 Quattro CV Joint Boot A3 Sportback e-tron CV Joint Boot A4 CV Joint Boot A4 Quattro CV Joint Boot A4 allroad CV Joint Boot A5 CV Joint Boot A5 Quattro CV Joint Boot A5 Sportback CV Joint Boot A6 CV Joint Boot A6 Quattro CV Joint Boot A6 allroad CV Joint Boot A7 Quattro CV Joint Boot A7 Sportback CV Joint Boot A8 CV Joint Boot A8 Quattro CV Joint Boot Allroad Quattro CV Joint Boot Cabriolet CV Joint Boot Coupe CV Joint Boot Coupe Quattro CV Joint Boot Q3 CV Joint Boot Q3 Quattro CV Joint Boot Q4 e-tron CV Joint Boot Q4 e-tron Sportback CV Joint Boot Q5 CV Joint Boot Q5 PHEV CV Joint Boot Q5 Sportback CV Joint Boot Q7 CV Joint Boot Q8 CV Joint Boot Q8 e-tron CV Joint Boot Q8 e-tron Sportback CV Joint Boot Quattro CV Joint Boot R8 CV Joint Boot RS Q8 CV Joint Boot RS e-tron GT CV Joint Boot RS3 CV Joint Boot RS4 CV Joint Boot RS5 CV Joint Boot RS5 Sportback CV Joint Boot RS6 Avant CV Joint Boot RS7 CV Joint Boot RS7 Sportback CV Joint Boot S3 CV Joint Boot S4 CV Joint Boot S5 CV Joint Boot S5 Sportback CV Joint Boot S6 CV Joint Boot S7 CV Joint Boot S7 Sportback CV Joint Boot S8 CV Joint Boot SQ5 CV Joint Boot SQ5 Sportback CV Joint Boot SQ7 CV Joint Boot SQ8 CV Joint Boot TT CV Joint Boot TT Quattro CV Joint Boot TT RS Quattro CV Joint Boot TTS Quattro CV Joint Boot V8 Quattro CV Joint Boot allroad CV Joint Boot e-tron GT CV Joint Boot e-tron Quattro CV Joint Boot e-tron S CV Joint Boot e-tron S Sportback CV Joint Boot e-tron Sportback CV Joint Boot