×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi A4 Valve Lifter

Lash Adjuster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Valve Lifters found

Audi A4 Valve Lifters Part Number: 022-109-423-D

$13.49 MSRP: $21.57You Save: $8.08 (38%)Ships in 1-2 Business DaysAudi A4 Lifter Part Number: 022-109-423

$4.35 MSRP: $5.67You Save: $1.32 (24%)Ships in 1-2 Business Days

Audi A4 Valve Lifter

Choose original equipment manufacturer Valve Lifter for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Valve Lifter at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A4 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A4 needs now.

Audi A4 Valve Lifter Parts and Q&A

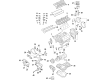

- Q: What precautions should be taken when working on the Camshaft and Valve Lifter to avoid setting a trouble code on Audi A4?A:This procedure can trigger a set trouble code; this can only be cleared by visiting a dealer service department or a repair shop that has the required scan tool that is capable of aligning the cam sensor. The camshafts and lifters must be carefully inspected before fitting and camshaft endplay must be inspected before removal. Even though hydraulic lifters are self-adjusting and do not need periodic servicing, there is a process of verifying hydraulic lifters that are excessively noisy. In the case of the 1.8L engine, firstly, take out the engine cover, Valve Cover, Timing Belt, camshaft sprocket, secondary air combination valve, and camshaft position sensor. Indicate the camshaft drive chain position against the sprockets and rear bearing cap with 16 rollers between marks. Tension the camshaft drive chain with either a special tool or a homemade tool. Identify the position of the camshaft bearing caps, loosen and remove the bearing cap nuts in a particular sequence, and remove the camshaft adjuster, and the two camshafts together with the adjustable. Take the lifters out of the Cylinder Head, and in order. In the case of the 2.0L engine, the steps include that of the cylinder head, the camshaft position sensor, clamp down on the camshafts using a locking tool, compress the camshaft drive chain tensioner, and unscrew the camshaft adjuster and guide frame. Check the bearings surfaces of the camshafts, camshaft journal and bearing clearances, check the camshaft runout, and camshaft endplay. Compare camshaft lobes and determine wear of lifters. Installation of the 1.8L engine includes lubricating the hydraulic lifters, fitting them into their bores, cleaning mating surfaces, aligning the marks of the drive chain, and fitting the camshafts in place. Fit the drive chain tensioner, bearings caps and camshaft oil seals and place the camshaft sprocker and timing belt. Clean and grease the camshafts and bearing surfaces, install the camshafts, guide frame, and camshaft adjuster and check the alignment of the timing belt of the 2.0L engine. The rest of the installation process is the same but in the reverse order of removal making sure that both TDC marks align once the engine has been rotated through two complete revolutions.

- Q: What precautions should be taken when performing this procedure to avoid triggering a trouble code and ensure proper installation of the camshaft and valve lifter on Audi A4?A:It is recommended to exercise caution because, when this procedure is performed it may enter a trouble code and thus the visit to a dealer service department or a repair shop that has the correct scan tool to align the cam sensor(s) and clear the trouble code is needed. There is a need to carefully inspect the camshafts and lifters during pre-installation, and to ensure that the endplay of camshafts is checked before removal. Valve / rain noise during cold start is normal on all V6 models, but it is the constant noise after a warm start that may necessitate the removal of the intake manifold and replacement of the oil check valves. On the 3.0L V6 engine, one should start with the removal of the engine and the Valve Covers followed by inspecting the lifters with the help of a feeler gauge. Next step is to remove Timing Belt, camshaft adjusters and rear timing belt cover, snapping harness off the camshaft adjuster solenoid housing and removing bolts on the solenoid housing. Relax the guide frame bolts, insert M6 bolts and use them to push the guide frame upwards and label the camshafts to identify them and then remove them together with the lifters, keeping them in their places. Clean and check the camshaft wear, then check the lobe height replacement of the camshaft may be required. Install the guide frame temporarily to check the endplay on the camshaft and to check the lobes. To install it, lubricate the lifters and camshaft, fit the camshafts, clean the mating surfaces, add a sealant and fit the guide frame, making sure that it is aligned with a special instrument. Install the locking tools and then assemble in the same sequence in reverse using new O-rings, and camshaft oil seals. Lastly, turn the crankshaft and ensure there is no interference and also get new lifters to bleed down at least 30 minutes before starting the vehicle. The 3.2L engine service is a labor intensive engine that needs special equipment and is only conducted by a qualified facility.