×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi A4 Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Intake Manifolds found

Audi A4 Intake Manifold Part Number: 078-129-617-A

$15.00 MSRP: $24.00You Save: $9.00 (38%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 058-129-617-D

$22.75 MSRP: $36.40You Save: $13.65 (38%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 8E0-129-618-H

$66.63 MSRP: $93.32You Save: $26.69 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 8E0-129-617-D

$67.82 MSRP: $94.99You Save: $27.17 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 8E0-129-617-E

$82.11 MSRP: $115.00You Save: $32.89 (29%)Ships in 1-2 Business DaysAudi A4 Air Inlet Duct Part Number: 8K0-129-617

$99.96 MSRP: $140.01You Save: $40.05 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06H-133-201-AN

$138.97 MSRP: $194.63You Save: $55.66 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06L-133-201-FR

$196.02 MSRP: $274.53You Save: $78.51 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06L-133-201-DH

$386.75 MSRP: $541.66You Save: $154.91 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06L-133-201-FP

$571.19 MSRP: $799.98You Save: $228.79 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06H-133-201-AR

$766.36 MSRP: $990.78You Save: $224.42 (23%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06F-133-201-P

$746.71 MSRP: $965.37You Save: $218.66 (23%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06E-133-109-BE

$868.69 MSRP: $1123.06You Save: $254.37 (23%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06E-133-110-BE

$868.69 MSRP: $1123.06You Save: $254.37 (23%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06E-133-210-P

$1422.04 MSRP: $1707.13You Save: $285.09 (17%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06B-133-201-F

$327.25 MSRP: $458.33You Save: $131.08 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06B-133-201-Q

$396.27 MSRP: $555.00You Save: $158.73 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06B-133-201-AP

$451.01 MSRP: $631.67You Save: $180.66 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06B-133-201-AQ

$467.06 MSRP: $654.15You Save: $187.09 (29%)Ships in 1-2 Business DaysAudi A4 Intake Manifold Part Number: 06E-133-125-K

$579.53 MSRP: $811.67You Save: $232.14 (29%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 24 Results

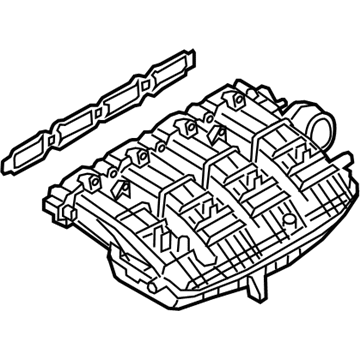

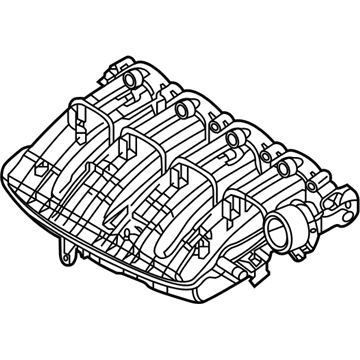

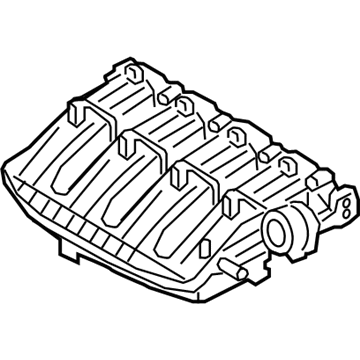

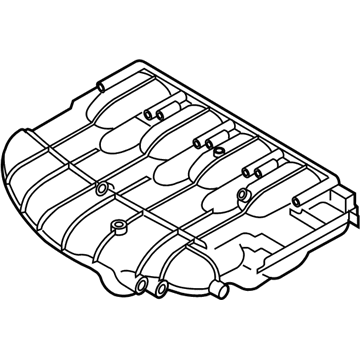

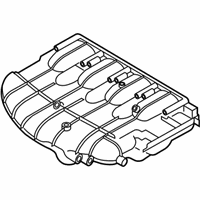

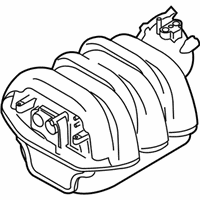

Audi A4 Intake Manifold

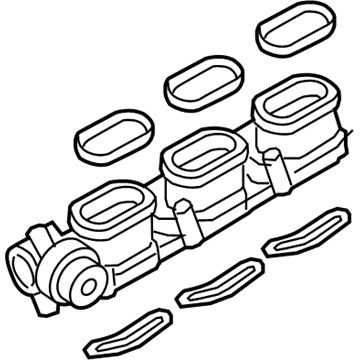

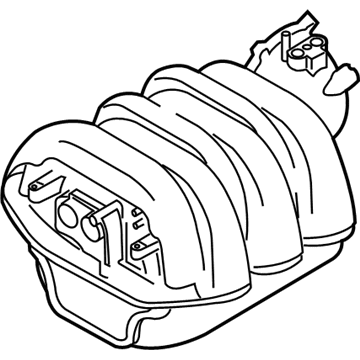

The Audi A4 Intake Manifold directs the exact quantity of air, or air combined with fuel, to every cylinder whereby the engine can make smooth and effective power. The first generation Audi sedans were powered with heavy cast iron or aluminum manifolds that were paired with either carburetors or throttle body injection where the Intake Manifold would then mix fuel and air before it could be distributed. With the emergence of electronic multiport systems, Audi also changed to runners that would only carry incoming air, with separate injectors spraying fuel near the valves, and the Intake Manifold shape remained significant to ensure even flow and tuned Helmholtz resonance which enhances the filling of the cylinder. Modern day generations are dependent on gasoline direct injection where the Intake Manifold feeds pure, cooler air only and plastic composite materials are applied instead of metal to reduce mass and maintain low temperatures to enhance combustion. Some Audi performance models use variable length runner technology whereby the runner can change its path length dynamically, and thus both low-speed torque and high-speed horsepower can be optimized. The seals to the cylinder head with gaskets (they have to remain airtight) are necessary regardless of time period, since any leakage can lean out the mixture, increase idle roughness, and reduce performance. The Audi engine computer provides the driver with real-time feedback from the temperature and pressure sensors in the manifold to adjust the spark and fuel in order to make each A4 react to the driver.

Choose original equipment manufacturer Intake Manifold for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Intake Manifold at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A4 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A4 needs now.

Audi A4 Intake Manifold Parts and Q&A

- Q: How to remove the intake manifold flap motor and related components on Audi A4?A:To remove the engine cover and the coolant expansion tank to 2.0L four-cylinder models. The second step is to remove the air intake hose in between the throttle body and the left intercooler. Unscrew the two screws which hold the electrical connector bracket to the coolant pipe, and also disconnect all electrical connectors around the intake flap motor. Snip the cable connections connecting the wiring harnesses to the coolant pipe, part the harnesses, and loosen the connector bracket. Unscrew the bolt that held the bracket with the coolant pipe and force the coolant pipe aside. With a screwdriver, loosen the screwdriver engages the intake flap motor control rod on the crank arm at the intake manifold and unscrew the intake flap motor mounting fasteners and the motor itself, and is reversed of installation. In the case of V6 models, in this case, the 3.0L, one needs to start with the engine cover, and next, unplug the electrical connector on the intake manifold change-over valve. De-elect the vacuum lines of both change-over valve and vacuum actuator and then remove change-over valve out of actuator. Unscrew the two vacuum actuator mounting screws and disassemble the actuator of the intake manifold, installing it being the opposite of the removal. In 3.2 L models, take off the front engine cover, which is then followed by disconnection of the electrical connectors to the intake manifold tuning valve position sensor and the change-over valve of the intake manifold flap. Deactivate the vacuum lines of the actuator and change-over valve of the intake manifold flap. The actuator or sensor can be removed by removing its mounting clamps, the change-over valve used with the intake manifold flap may be removed just by pulling it out of the bracket, and installation is the converse of removal.

- Q: How to remove and reinstall the upper intake manifold for V6 engines on Audi A4?A:The next process is used on 3.0L engines and on the upper intake manifold of 3.2L engines. Firstly, it is important to take the pressure off the fuel system and take the cable off the battery negative post. Semi-drain the engine coolant, and disconnect the electrical connector of throttle body. Take out the engine covers, air intake tube, air filter housing, and coolant expansion tank. Unscrew the crankcase breather tube of the Valve Covers and rear of the intake manifold, labeling and disconnecting any hoses or electrical connectors at the intake manifold. Take out the oil dipstick and the bolt that holds the dipstick tube to the valve cover and turn the tube so that it will be out of the way. Take off the ignition coils and lay the harnesses aside, and then take off the bolts holding the AIR pipe to the heads or the valve covers. In the case of an engine that uses 3.0L, de-fit the fuel rail and injectors. Disassemble and take off mounting fasteners and the manifold of the engine. Wipe all traces of gasket material off the manifold and the Cylinder Head and remove the O-ring gaskets off of the receiver grooves on the intake manifold when fitted. Wipe down the mating surfaces of the cylinder head and the manifold with brake system cleaner and inspect the manifold with a straightedge, any warpage will require replacement. Install new gaskets and O-rings on the receiver grooves on the manifold, mount the manifold on the engine, and install the bolts. Install the fasteners with three or four similar force to the given specification, moving towards the ends through the center to prevent warping of the manifold. Install the rest of the parts in the reverse sequence of the sequence of removal, and a new O-ring in the bottom of the dipstick tube should be installed in case it was fully removed, and lubricated with clean engine oil. Check throttle linkage to operate easily before starting the engine, refill and bleed the cooling system and run the engine to check on the coolant and vacuum leakage.

Related Audi A4 Parts

Browse by Year

2020 Intake Manifold 2019 Intake Manifold 2018 Intake Manifold 2017 Intake Manifold 2016 Intake Manifold 2015 Intake Manifold 2014 Intake Manifold 2013 Intake Manifold 2012 Intake Manifold 2011 Intake Manifold 2010 Intake Manifold 2009 Intake Manifold 2008 Intake Manifold 2007 Intake Manifold 2006 Intake Manifold 2005 Intake Manifold 2004 Intake Manifold 2003 Intake Manifold 2002 Intake Manifold 2001 Intake Manifold 2000 Intake Manifold 1999 Intake Manifold 1998 Intake Manifold 1997 Intake Manifold 1996 Intake Manifold