×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine 1994 Audi 100 Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Cylinder Head found

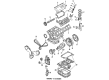

1994 Audi 100 Cylinder Head Part Number: 078-103-351-A

$1077.45 MSRP: $1207.22You Save: $129.77 (11%)Ships in 1-2 Business DaysProduct Specifications- Item Weight: 35.00 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 078-103-351-A

- Warranty: This genuine part is guaranteed by Audi's factory warranty.

1994 Audi 100 Cylinder Head Parts and Q&A

- Q: What are the steps involved in cylinder head dismantling and overhaul for 4-cylinder diesel engines on 1994 Audi 100?A: There are a number of steps involved in cylinder head dismantling and overhaul, which include disconnection of battery negative lead, emptying the engine oil and cooling system, and removing the auxiliary drivebelts. The top cover of the engine and the camshaft cover shall be removed and the engine adjusted to TDC in No 1 cylinder. The injection pump sprockets, camshaft and timing belt tensioner are then loosened off, as well as the timing belt inner cover. The rad, expansion tank, heater inlet and outlet coolant hose are no longer attached to the cylinder head. The fuel system pipes, leak off hoses, and electrical cables are also unconnected as well as the wiring plug of the coolant temperature sensor. The exhaust down pipe is disconnected to the exhaust manifold, turbocharger is disconnected and EGR valve and pipework removed where necessary. The engine harness connector bracket is taken away and the cylinder head bolts are gradually loosened and loosened and removed and discarded. All that is connected is confirmed not to be connected after which the cylinder head is pulled out of the block and the gasket is removed keeping track of the locating dowels. In the case of manifold separation, the bolts holding in the inlet manifold are disassembled, then the heat shield and the exhaust manifold retaining nuts are also removed and all the mating surfaces are clean by fitting them again. The new gaskets are attached to the new exhaust manifold and the heat shield is reinstalled. Another inlet manifold gasket is installed and the inlet manifold is clamped. The cleaning and checking of the mating faces should be done before refitting the cylinder head. In case of warpage, a straight-edge is employed to check the same. Cleaning of drillings on cylinder head bolts and placement of the crankshaft is done to ensure that during the refitting, no damage occurs to the pistons. New head gasket is positioned on the cylinder block in a proper position and alignment dowels are made of old bolts. The block is then fitted with the cylinder head, making sure that the gasket is fitted, and the alignment dowels are taken off. New cylinder head bolts are lubed with grease and oil, and fitted and screwed into position in a certain order to the necessary amounts of torque and then angle-tightened. Once the engine has been positioned on No 1 cylinder at the TDC, the other components are assembled back and the cooling system and oil to the engine are replenished.