×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi A4 Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Flywheels found

Audi A4 Drive Plate Part Number: 078-105-323-G

$296.31 MSRP: $415.00You Save: $118.69 (29%)Ships in 1-2 Business DaysAudi A4 Drive Plate Part Number: 06C-105-269-A

$600.95 MSRP: $776.92You Save: $175.97 (23%)Ships in 1-2 Business DaysAudi A4 Drive Plate Part Number: 06H-105-323-R

$243.95 MSRP: $341.66You Save: $97.71 (29%)Ships in 1-2 Business DaysAudi A4 Drive Plate Part Number: 078-105-323-A

$291.55 MSRP: $408.33You Save: $116.78 (29%)Ships in 1-2 Business DaysAudi A4 Drive Plate Part Number: 06H-105-323-AE

$349.86 MSRP: $490.00You Save: $140.14 (29%)Ships in 1-2 Business DaysAudi A4 Drive Plate Part Number: 06H-105-323-P

$351.04 MSRP: $491.65You Save: $140.61 (29%)Ships in 1-2 Business DaysAudi A4 Drive Plate Part Number: 06H-105-323-K

$381.03 MSRP: $533.65You Save: $152.62 (29%)Ships in 1-2 Business DaysAudi A4 Drive Plate Part Number: 078-105-323-C

$385.56 MSRP: $540.00You Save: $154.44 (29%)Ships in 1-2 Business DaysAudi A4 Drive Plate Part Number: 06E-105-323-D

$404.59 MSRP: $566.65You Save: $162.06 (29%)Ships in 1-2 Business DaysAudi A4 Flywheel Part Number: 058-105-266

$595.00 MSRP: $769.23You Save: $174.23 (23%)Ships in 1-2 Business DaysAudi A4 Drive Plate Part Number: 078-105-323-B

$679.73 MSRP: $878.77You Save: $199.04 (23%)Ships in 1-2 Business DaysAudi A4 Flywheel Part Number: 06C-105-266-B

$891.31 MSRP: $1152.31You Save: $261.00 (23%)Ships in 1-2 Business DaysAudi A4 Flywheel Part Number: 058-105-266-H

$1189.99 MSRP: $1538.45You Save: $348.46 (23%)Ships in 1-2 Business DaysAudi A4 Flywheel Part Number: 06D-105-266-C

$1262.70 MSRP: $1515.84You Save: $253.14 (17%)Ships in 1-2 Business DaysAudi A4 Flywheel Part Number: 06E-105-266-AA

$1495.83 MSRP: $1795.71You Save: $299.88 (17%)Ships in 1-2 Business DaysAudi A4 Torque Converter Part Number: 0B5-105-317-K

$1792.14 MSRP: $2151.44You Save: $359.30 (17%)Ships in 1-2 Business DaysAudi A4 Flywheel Part Number: 0B1-105-266-AG

$1469.64 MSRP: $1764.27You Save: $294.63 (17%)Ships in 1-2 Business DaysAudi A4 Flywheel Part Number: 0B2-105-266-R

$1864.73 MSRP: $2238.57You Save: $373.84 (17%)Ships in 1-2 Business DaysAudi A4 Flywheel Part Number: 078-105-266-D

$1755.25 MSRP: $2107.14You Save: $351.89 (17%)Ships in 1-2 Business Days

Audi A4 Flywheel

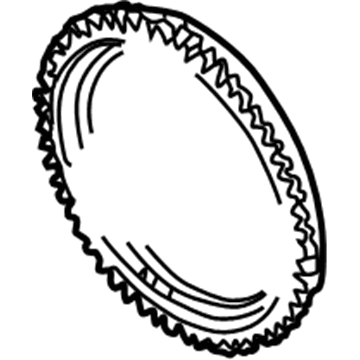

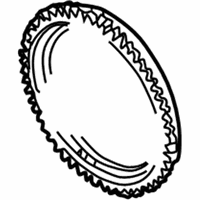

The Audi A4 Flywheel is in the middle of this mechanism that gives every engine firing smooth and reliable power. This large, hefty disc of steel is bolted to the crankshaft to store rotational energy in such a manner so that the occasional combustion strokes appear to be one continuous rush, and the outer ring gear of the disc engages with the starter motor to rotate the crank when the engine ignites. The clutch disc is also clamped by a machined face that allows drivers to disconnect or reconnect the drivetrain during a shift. There have been two primary designs applied over the years by Audi. The traditional solid Flywheel is a single mass that can typically be resurfaced in case any heat spots or grooves form, which will redefine a true and flat contact surface. The more recent dual mass Flywheel, consisting of primary and secondary plates with a spring-filled damper between, suppresses more noise and aids in quieting the cabin, which may be of particular importance in the Audi cabin of the time. But the internal damper can wear out and is not advisable to machine and is actually not promoted by the manufacturers, thus they suggest replacement as the common remedy. Every Flywheel will wear due to the heat of constant contact with clutches, distorted faces, or broken ring gear teeth that will require attention on any Audi sedan. The selection of a direct Audi specification maintains a balanced engine and transmission to move as desired by an A4 owner in day-to-day drive.

Choose original equipment manufacturer Flywheel for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Flywheel at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A4 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A4 needs now.

Audi A4 Flywheel Parts and Q&A

- Q: How to remove and install the flywheel/driveplate on Audi A4?A:The procedure for removal and installation of the flywheel/driveplate on V6 engines is similar to that of the four-cylinder engine. For engines with the dual-mass flywheel, rotate the engine to TDC and install the TDC timing stop in the front of the block. Use a flywheel-holding tool on the ring gear to secure the flywheel. Turn the rearmost section of the dual-mass flywheel by hand until the flywheel mounting bolts are centered in their openings, and remove the bolts using only hand tools, avoiding impact tools to prevent damage. The dual-mass flywheel features a needle-bearing insert that can be removed with a puller and installed with a driver. In models with Multitronic transmission, the flywheel is equipped with a damper similar to a clutch plate on a manual transmission application, which must be removed to access the flywheel bolts.

- Q: What precautions should be taken when removing and installing a flywheel/driveplate on Audi A4?A:The manufacturer advises the use of new flywheel/driveplate bolts whenever removed. In order to start the process of eliminating a standard flywheel/driveplate, the vehicle is raised and placed safely on jackstands, followed by the transaxle removal. In case of leakages, the front pump seal O-ring of the automatic transaxle or the input shaft seal of the manual transaxle should be replaced. In cars with manual transaxles, disassemble the pressure plate and disc clutch in order to have a chance to inspect or replace the parts of the clutch. Mark the location of the flywheel/ drive plate and crankshaft, so as to use them as an alignment mark when re-assembling. Tear the bolts attaching the flywheel/ driveplate to the crankshaft, jam the flywheel with a screwdriver in case the crankshaft starts to move. The flywheel/driveplate should be carefully pulled off, holding it in place as the final bolt is removed and any spacers used in the automatic transaxle bodies must be retained with the driveplate. With dual-mass flywheels, rotate engine to TDC and fit timing stop, fix flywheel with flywheel-holding tool. Take off the clutch and indicate the association of block with flywheel. Install the flywheel mounting bolts on the flywheel mounting holes and loosen them with a hand tool, but do not touch the openings when loosening or they are likely to be damaged. A flywheel that is dual-mass contains a needle-bearing insert which can be pulled off using a puller and attached using a driver. In models with Multitronic transmission, the damper should be removed in order to access the flywheel bolts. Installation To install, clean the flywheel with brake system cleaner and examine it, looking for damage, and checking it against a straight-edge to see whether it is warped. Wipe and wipe the mating parts of the flywheel/driveplate and crankshaft, and change the crankshaft rear seal in case it is leaky. Place the flywheel/driveplate and spacer on the crankshaft, so that the marks made on removal may be in alignment, and thread locking compound applied to the threads of the bolts before installation. Working up to the full torque in three or four steps, screwdriver Use a screwdriver to hold the flywheel/driveplate stationary as the bolts are tightened in a criss-cross pattern. In the case of cars that have an automatic transaxle, an installed height of the driveplate should be measured at three equal points and shimmed where needed to reach the required height. The rest of the installation goes in the opposite sequence of uninstallation.

Related Audi A4 Parts

Browse by Year

2020 Flywheel 2019 Flywheel 2018 Flywheel 2017 Flywheel 2016 Flywheel 2015 Flywheel 2014 Flywheel 2013 Flywheel 2012 Flywheel 2011 Flywheel 2010 Flywheel 2009 Flywheel 2008 Flywheel 2007 Flywheel 2006 Flywheel 2005 Flywheel 2004 Flywheel 2003 Flywheel 2002 Flywheel 2001 Flywheel 2000 Flywheel 1999 Flywheel 1998 Flywheel 1997 Flywheel 1996 Flywheel