×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi A4 Driveshaft

Drive Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Driveshafts found

Audi A4 Drive Shaft Assembly Part Number: 8W0-521-101-H

$1096.61 MSRP: $1417.72You Save: $321.11 (23%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Assembly Part Number: 8K0-521-101-AA

$1872.33 MSRP: $2247.69You Save: $375.36 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Assembly Part Number: 8W0-521-101-A

$1944.33 MSRP: $2334.12You Save: $389.79 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Assembly Part Number: 8K0-521-101-AC

$2008.95 MSRP: $2411.70You Save: $402.75 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Assembly Part Number: 8K0-521-101-S

$2008.95 MSRP: $2411.70You Save: $402.75 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Assembly Part Number: 8K0-521-101

$1559.65 MSRP: $1872.33You Save: $312.68 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Assembly Part Number: 8K0-521-101-K

$1962.89 MSRP: $2356.41You Save: $393.52 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Assembly Part Number: 8K0-521-101-T

$2255.40 MSRP: $2707.57You Save: $452.17 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Assembly Part Number: 8W0-521-101-J

$2374.05 MSRP: $2850.00You Save: $475.95 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Part Number: 8D0-521-101-G

$1403.61 MSRP: $1685.00You Save: $281.39 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Part Number: 8D0-521-101-H

$1403.61 MSRP: $1685.00You Save: $281.39 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Part Number: 8E0-521-101-C

$1475.60 MSRP: $1771.43You Save: $295.83 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Part Number: 8E0-521-101-E

$1555.33 MSRP: $1867.14You Save: $311.81 (17%)Ships in 1-2 Business DaysAudi A4 Drive Shaft Part Number: 8D0-521-101-B

$1661.84 MSRP: $1995.00You Save: $333.16 (17%)Ships in 1-2 Business DaysAudi A4 Propeller Shaft Part Number: 8E0-521-101-AB

$1963.50 MSRP: $2357.15You Save: $393.65 (17%)Ships in 1-2 Business DaysAudi A4 Propeller Shaft Part Number: 8E0-521-101-T

$2022.99 MSRP: $2428.56You Save: $405.57 (17%)Ships in 1-2 Business Days

Audi A4 Driveshaft

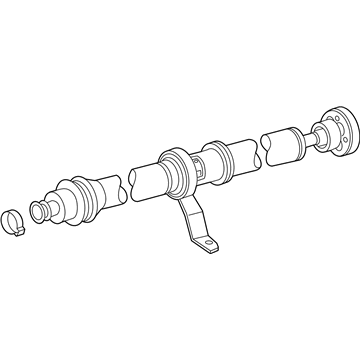

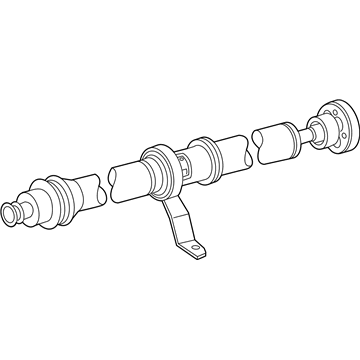

The Audi A4 Driveshaft is a key component that transmits engine torque to remote drive parts, allowing the car to move efficiently even when the suspension parts move during driving. Constructed to be a carrier of torque, this narrow Driveshaft tube is subject to high torque and shear forces, so Audi designers choose metals that remain strong without becoming heavy, which reduces inertia and fuel consumption. Since power has to traverse the space between the gearbox and the independent rear axle fitted to most Audi models, the Driveshaft uses universal joints and occasionally rag or jaw couplings, which allow angles to change without interrupting rotation. A splined or prismatic section is applied that slides in and out to absorb the changes in length as the vehicle bounces over bumps so that it does not bind up. Most of the various models in the A4 line use the same basic design of the Driveshaft, but earlier models mainly applied plain cross-type universal joints, whereas later models combined those joints with high-tech splined sleeves to operate with less noise, the primary difference in styles. Whatever the year, all the Driveshafts in an Audi strike a balance between strength and mass so that whatever the engine is producing is the same torque at the wheels. This attention to effective power provision contributes to keeping the heritage of Audi with its assured all-wheel-drive performance.

Choose original equipment manufacturer Driveshaft for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Driveshaft at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A4 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A4 needs now.

Audi A4 Driveshaft Parts and Q&A

- Q: What precautions should be taken when handling the driveshaft to prevent bending and ensure proper installation on Audi A4?A:One should take care not to bend the driveshaft more than 25 degrees, and it is preferable to hold the two parts straight with a holding fixture, which can be a piece of 2x4 of the right size with wooden blocks on one end. When there is no available support that holds up the driveshaft in a level plane, a floor jack or assistance would be used. Today, there are no spare parts of the driveshaft, and in case such components as CV Joint, U-joint, or center support bearing are damaged, the whole drive shaft has to be changed; it is advisable to hire a specialist on the driveline to get advice on the possible repair. One should start by raising the vehicle safely on jackstands and then take off the back part of the exhaust system. Peel off and remove the front rivets/mounting fasteners of the heat shield, one side of the mounting fastener at a time and align the center support bearing bracket tabs with the center of the outer holes of the floor pan. Align the relationship between the CV joints and flanges and clamp each end of the driveshaft and loosen the bolts that fix the CV joints to the companion flanges, avoiding the rotation with a chain wrench. Then detach the fasteners connecting the center support bearing bracket to the floorpan, and any shims and record their locations and then take pains to lower and remove the driveshaft underlying the vehicle. Removal should be reversed, so it is necessary to install fresh gasket material and remove old CV joint bolts and install new ones, install new gaskets, replace the heat shield (which dropped out of place) and install any shims in their correct places. Prior to installing the center support with the bracket fasteners, ensure that the centering tabs are aligned with the holes on the outer floorpan, and new sheet metal rivets/clips are fitted on the heat shield front mounting holes, and lastly, tight all the fasteners accordingly to the recommended torque values.

Related Audi A4 Parts

Browse by Year

2020 Driveshaft 2019 Driveshaft 2018 Driveshaft 2017 Driveshaft 2016 Driveshaft 2015 Driveshaft 2014 Driveshaft 2013 Driveshaft 2012 Driveshaft 2011 Driveshaft 2010 Driveshaft 2009 Driveshaft 2008 Driveshaft 2007 Driveshaft 2006 Driveshaft 2005 Driveshaft 2004 Driveshaft 2003 Driveshaft 2002 Driveshaft 2001 Driveshaft 2000 Driveshaft 1999 Driveshaft 1998 Driveshaft 1997 Driveshaft 1996 Driveshaft