×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi 100 Cooling Fan Assembly

Engine Cooling Fan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Cooling Fan Assemblys found

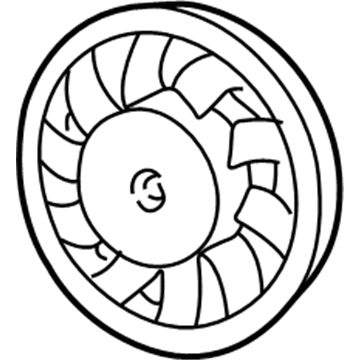

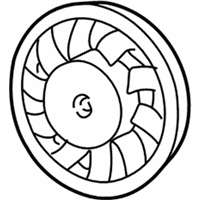

Audi 100 Fan Clutch Part Number: 441-959-465

$77.83 MSRP: $109.00You Save: $31.17 (29%)Ships in 1-2 Business DaysAudi 100 Fan Clutch Part Number: 4A0-959-465-A

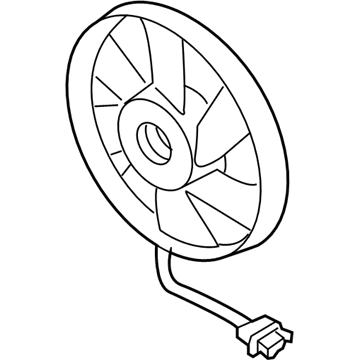

$108.73 MSRP: $152.28You Save: $43.55 (29%)Ships in 1-2 Business DaysAudi 100 Fan & Motor Part Number: 4A0-959-455-C

$310.59 MSRP: $435.00You Save: $124.41 (29%)Ships in 1-2 Business DaysAudi 100 Fan Clutch Part Number: 4A0-959-465

$99.78 MSRP: $129.00You Save: $29.22 (23%)Ships in 1-2 Business DaysAudi 100 Fan Blade Part Number: 443-959-465-B

$118.41 MSRP: $165.83You Save: $47.42 (29%)Ships in 1-2 Business DaysAudi 100 Fan & Motor Part Number: 443-959-455-N

$431.97 MSRP: $605.00You Save: $173.03 (29%)Ships in 1-2 Business Days

Audi 100 Cooling Fan Assembly

Choose original equipment manufacturer Cooling Fan Assembly for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Cooling Fan Assembly at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi 100 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your 100 needs now.

Audi 100 Cooling Fan Assembly Parts and Q&A

- Q: How do the Cooling Fan Assembly systems operate, and How to troubleshoot and replace them on Audi 100?A:Every 4-cylinder engine has electrically operated cooling fan(s), each 5-cylinder engine has the main fan powered by the auxiliary drivebelt using a viscous coupling, and any auxiliary fan is electrically operated. This is connected to the ignition switch by a fuse and connected to the cooling fans which is completed by the cooling fan thermostatic switch on the left side of the Radiator. When one of the fans fails to work the engine must be operated until normal operating temperature is reached at which point it can be left to idle; the fan should be started a little bit later. Otherwise, it should be turned off and the wiring plug of the cooling fan switch detached. The ignition may be checked by attaching the corresponding contacts of the wiring plug to a spare wire when the ignition is on to check whether the switch is defective or not. Assuming that the fan remains inoperative, battery voltage should be checked at the feed wire to the switch and continuity between the switch earth terminal and a good earth point on the body should be checked. When the switch and wiring are good, it is possible that the motor itself is faulty and will be checked by connecting a 12-volt supply to the motor directly. To dismantle the radiator, the retaining bolts of the fan shroud assembly are to be loosened and detached then the motor wiring is to be unclipped and the retaining nuts are to be undone to disconnect the motor assembly and the shroud. In case there is a fault with the motor, the motor should be substituted as a unit. When refitting, the motor assembly is to be fixed in place to the shroud with appropriate routing of the motor wiring and then the shroud assembly is refixed to the radiator. In 5-cylinder engines, the operation of the viscous coupling is visually inspected with respect to leaking fluids and damage of the fan blades, and the fan is supposed to rotate freely when cold and clog when hot. In the case of the coupler being desired to be eliminated, the locating sleeves are to be unhooked to disconnect the bonnet release cable, and the attaching bolts of the radiator upper mounting brackets to be removed. Alignment marks are to be made, then crossmember should be cleared of the radiator. An open ended spanner is used to unscrew the coupling out of its drive pulley, but the drive pulley is retained with a peg spanner. The fan and coupling equipment is then moved out of position. To refit the fan blade, one must fit the blade to the coupling properly and then clamp on the assembly to the drive pulley and tighten it to the required torque. The bonnet locking crossmember, radiator upper mounting brackets are then re-fitted and all the parts are firmly screwed in place and the bonnet release cable guides are clipped back into place.