×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi Wiper Linkage

Wiper Blade- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

65 Wiper Linkages found

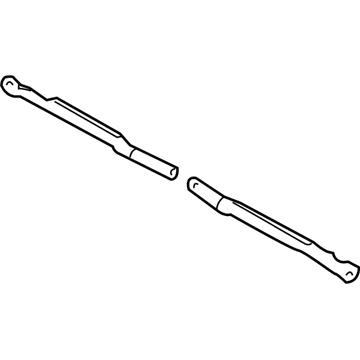

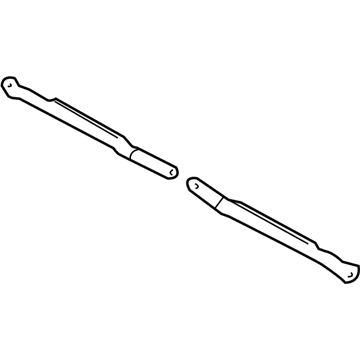

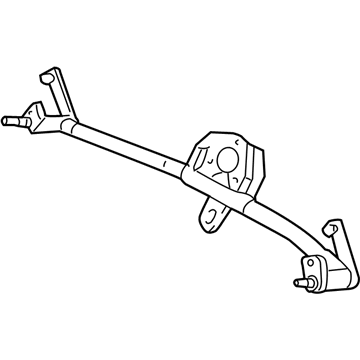

Audi Linkage Rod Part Number: 8N0-955-325

$13.75 MSRP: $22.00You Save: $8.25 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rod; Link

- Position: Right

Audi Wiper Transmission Part Number: 8D1-955-325

$22.86 MSRP: $36.57You Save: $13.71 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rod; Wiper Transmission

- Position: Left

- Replaces: 8D1-955-331

Audi Wiper Transmission Part Number: 8D1-955-326-B

$22.24 MSRP: $35.58You Save: $13.34 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rod; Link, Linkage Rod

- Replaces: 8D1-955-332

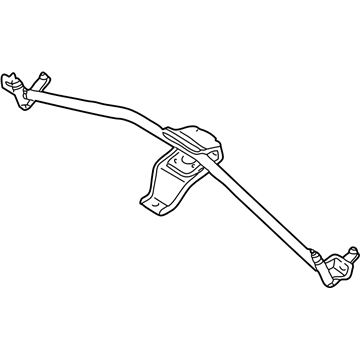

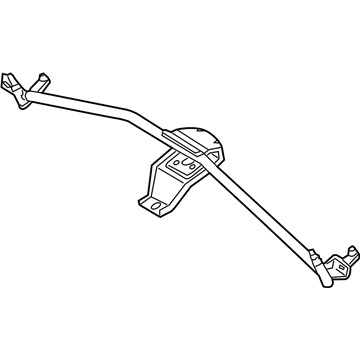

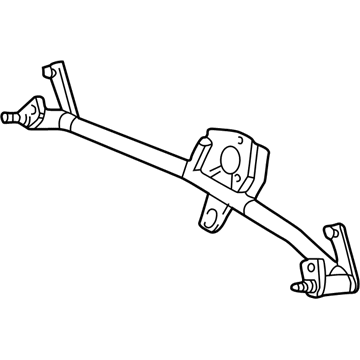

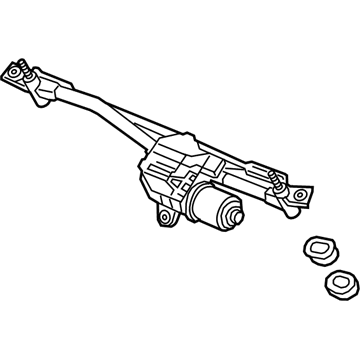

Audi Wiper Transmission Part Number: 8D1-955-603-A

$145.18 MSRP: $203.33You Save: $58.15 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Wiper Transmission

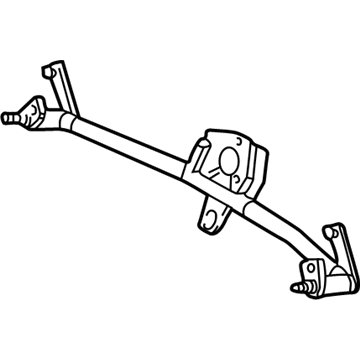

Audi Wiper Transmission Part Number: 4B1-955-603-A

$182.07 MSRP: $255.00You Save: $72.93 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Wiper Transmission

Audi Wiper Transmission Part Number: 8G0-955-603

$189.21 MSRP: $265.00You Save: $75.79 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket

Audi Wiper Transmission Part Number: 4B1-955-603-B

$198.73 MSRP: $278.33You Save: $79.60 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Wiper Transmission

Audi Wiper Transmission Part Number: 8N1-955-023-A

$213.01 MSRP: $298.33You Save: $85.32 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Wiper Transmission

- Replaces: 8N1-955-603

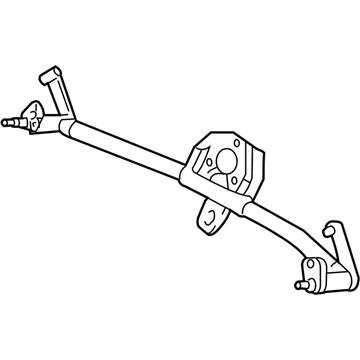

Audi Wiper Transmission Part Number: 8E1-955-319

$227.29 MSRP: $318.33You Save: $91.04 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rod; Crank Arm, Wiper Transmission

- Replaces: 8E0-955-121, 8E1-955-326-A

Audi Wiper Transmission Part Number: 4B7-955-603

$235.62 MSRP: $330.00You Save: $94.38 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Base

Audi Linkage Rod Part Number: 8H1-955-319

$258.81 MSRP: $362.49You Save: $103.68 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rod; Crank Arm

- Replaces: 8H1-955-326, 8E1-955-325-A

Audi Wiper Transmission Part Number: 8E1-955-603-D

$302.01 MSRP: $422.97You Save: $120.96 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Wiper Transmission

- Replaces: 8E1-955-603-B, 8E1-955-603-C

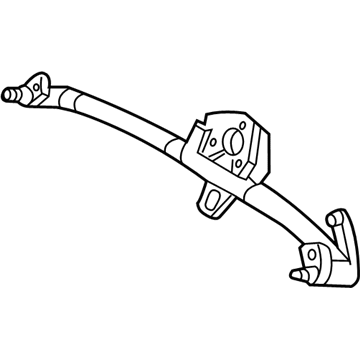

Audi Wiper Transmission Part Number: 8H1-955-603-A

$289.17 MSRP: $405.00You Save: $115.83 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Wiper Frame, Wiper Linkage

- Replaces: 8H1-955-603

Audi Wiper Transmission Part Number: 8W7-955-023-F

$366.51 MSRP: $513.32You Save: $146.81 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Motor Linkage, Wiper Transmission

- Replaces: 8W7-955-023-D

Audi Front Transmission Part Number: 83B-955-023-D

$303.45 MSRP: $425.00You Save: $121.55 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Front Transmission, Motor Linkage

- Replaces: 83B-955-023-C, 83B-955-023-A

Audi Wiper Transmission Part Number: 4D1-955-603-D

$321.30 MSRP: $450.00You Save: $128.70 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Wiper Frame

- Replaces: 4D1-955-603-A

Audi Wiper Transmission Part Number: 8W6-955-023-F

$379.44 MSRP: $531.43You Save: $151.99 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Motor Linkage, Wiper Transmission

- Replaces: 8W6-955-023, 8W6-955-023-D, 8W6-955-023-B

Audi Wiper Transmission Part Number: 4K1-955-023-B

$415.77 MSRP: $582.31You Save: $166.54 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Motor Linkage, Wiper Transmission

- Replaces: 4K1-955-023, 4K1-955-023-A

Audi Front Transmission Part Number: 4KL-955-023-B

$278.75 MSRP: $390.40You Save: $111.65 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Front Transmission, Motor Linkage

- Replaces: 4KL-955-023, 4KL-955-023-A

Audi Wiper Transmission Part Number: 8W1-955-023-C

$445.06 MSRP: $623.33You Save: $178.27 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket; Front Motor, Wiper Linkage, Wiper Transmission

- Replaces: 8W1-955-023-A, 8W1-955-023-B

| Page 1 of 4 |Next >

1-20 of 65 Results

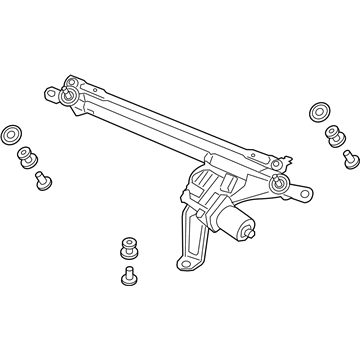

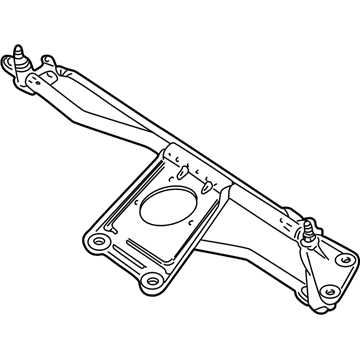

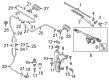

Audi Wiper Linkage

The Audi Wiper Linkage is a very important part of your vehicle. Therefore, it has to be maintained in good condition to avoid performance issues and comfortable driving. And these regular checks and replacements will ultimately save you some big repair costs. It is better to choose OEM parts when it comes to the time for fixing them. Why? Because they fit perfectly well and ensure safety. For people who prefer doing their maintenance, the genuine Audi Wiper Linkage is quite perfect. At AudiPartsGiant.com, we specialize in genuine Audi Wiper Linkages only. Also, we offer an extensive online catalog with many categories, ample stock, and secure shopping. The Audi Wiper Linkage is shipped directly from authorized Audi dealers at competitive prices. So trust us, and we will give you nothing but superior service. Depend on us for all your genuine parts needs, and then we will keep your automobile moving smoothly.

Audi Wiper Linkage Parts and Q&A

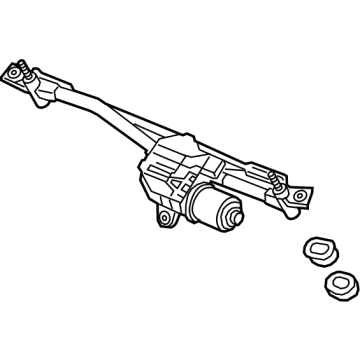

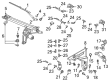

- Q: How to remove the Windshield Wiper Motors and Wiper Linkage assembly on Audi 100?A:In order to change the wiper motor assembly, you have to first unscrew the battery negative connector. Then take out the wiper arms in the same manner. Removal by unclips The water deflector panel can be removed by clipping out and removing the panel behind the engine compartment bulkhead. Unscrew the retaining bolts and remove the vent panel and the shroud at the bottom of the windscreen. Weaken the bolts holding the vent bracket to the linkage to obtain the required clearance to be removed. Next, loosen and unscrew the mounting bolts, manipulate the wiper motor assembly out of the position and disconnect the wiring connector as it becomes visible. Reinstall the spacer that is attached to the center mounting. To disassemble the motor and linkage, firstly, prise the linkage arms off the motor balljoint, and then unscrew the three retaining bolts and then take the motor out. To refit, complete the opposite procedure of removing, but make sure that the mounting bolts are tightened to the desired amount of torque, as well as that the water deflector panel is properly clipped into place.

- Q: How to remove and refit the front Windshield Wiper Motors and Wiper Linkage control unit on Audi A3?A:The wipers will have a wiper motor control unit built in to the motor, which has an APP (alternating park position) feature that slightly elevates the wipers arm position every second time the wipers are switched off to keep the wiper blades efficient. When the motor crank is not connected, it is necessary to reset it by turning off the APP facility, which is not accessible to any home-based mechanic, so it is very important to mark up the crank with reference to the spindle of the motor before detaching it. Reactivation can be automatically reactivated after 100 wiper motions, which is also applicable to new motors. Start by taking out the wiper arms and unconnection of the battery negative lead. Then unscrew the rubber sealing strip on the top of the bulkhead, unclip the washer jets on the windscreen cowling, unconnect the washer pipe and wiring connector then carefully remove the plastic windscreen cowling off the windscreen seal, without using a screwdriver, as this will crack the windscreen. Unscrew the mounting bolts, unplug the wiring plug of the wiper motor and maneuver the windscreen wiper motor and linkage out of the scuttle. When needed, remove recover washers and spacers of the motor mounting rubbers, make sure they are free of damage and replace when needed. To decouple the motor and the linkage, make alignment marks between the motor spindle and the linkage, unscrew the nut holding the linkage crank to the motor spindle, unscrew the three bolts holding the motor to the mounting plate and remove the motor. To re-fit, reversing the dis-fitting procedure is necessary, and before placing the washers and spacers it is important to ensure that the marks left by the removal process are aligned, the wiper motor linkage properly mounted with the rubber grommet in the bulkhead, the windscreen cowling mounting slots must be lubricated with silicone based spray lubricant and the wiper arms must be fitted carefully.

Related Audi Parts

Browse by Model

100 Quattro Wiper Linkage 100 Wiper Linkage 200 Quattro Wiper Linkage 200 Wiper Linkage 4000 Quattro Wiper Linkage 4000 Wiper Linkage 5000 Quattro Wiper Linkage 5000 Wiper Linkage 80 Quattro Wiper Linkage 80 Wiper Linkage 90 Quattro Wiper Linkage 90 Wiper Linkage A3 Quattro Wiper Linkage A3 Sportback e-tron Wiper Linkage A3 Wiper Linkage A4 Quattro Wiper Linkage A4 Wiper Linkage A4 allroad Wiper Linkage A5 Quattro Wiper Linkage A5 Sportback Wiper Linkage A5 Wiper Linkage A6 Quattro Wiper Linkage A6 Wiper Linkage A6 allroad Wiper Linkage A7 Quattro Wiper Linkage A7 Sportback Wiper Linkage A8 Quattro Wiper Linkage A8 Wiper Linkage Allroad Quattro Wiper Linkage Cabriolet Wiper Linkage Coupe Quattro Wiper Linkage Coupe Wiper Linkage Q3 Quattro Wiper Linkage Q3 Wiper Linkage Q5 PHEV Wiper Linkage Q5 Sportback Wiper Linkage Q5 Wiper Linkage Q7 Wiper Linkage Q8 Wiper Linkage Q8 e-tron Sportback Wiper Linkage Q8 e-tron Wiper Linkage Quattro Wiper Linkage R8 Wiper Linkage RS Q8 Wiper Linkage RS3 Wiper Linkage RS4 Wiper Linkage RS5 Sportback Wiper Linkage RS5 Wiper Linkage RS6 Avant Wiper Linkage RS7 Sportback Wiper Linkage RS7 Wiper Linkage S3 Wiper Linkage S4 Wiper Linkage S5 Sportback Wiper Linkage S5 Wiper Linkage S6 Wiper Linkage S7 Sportback Wiper Linkage S7 Wiper Linkage S8 Wiper Linkage SQ5 Sportback Wiper Linkage SQ5 Wiper Linkage SQ7 Wiper Linkage SQ8 Wiper Linkage TT Quattro Wiper Linkage TT RS Quattro Wiper Linkage TT Wiper Linkage TTS Quattro Wiper Linkage V8 Quattro Wiper Linkage allroad Wiper Linkage e-tron Quattro Wiper Linkage e-tron S Sportback Wiper Linkage e-tron S Wiper Linkage e-tron Sportback Wiper Linkage