×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi A3 Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Rod Bearings found

Audi A3 Bearings Part Number: 06H-105-701-P-BLA

$20.63 MSRP: $33.00You Save: $12.37 (38%)Ships in 1-2 Business DaysAudi A3 Bearings Part Number: 06H-105-701-P-ROT

$20.63 MSRP: $33.00You Save: $12.37 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-561-AF-GLB

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-561-AF-ROT

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-561-AF-SWA

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-561-AF-VIO

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-561-AF-WEI

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-591-AF-BLA

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-591-AF-GLB

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-591-AF-ROT

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-591-AF-SWA

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-591-AF-VIO

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Main Bearings Part Number: 06K-105-591-AF-WEI

$29.24 MSRP: $46.78You Save: $17.54 (38%)Ships in 1-2 Business DaysAudi A3 Bearings Part Number: 06D-105-701-K-GLB

$32.49 MSRP: $51.98You Save: $19.49 (38%)Ships in 1-2 Business DaysAudi A3 Bearing Part Number: 06H-105-701-E-GLB

$32.49 MSRP: $51.98You Save: $19.49 (38%)Ships in 1-2 Business DaysAudi A3 Connecting Rod Bearing Part Number: 06K-105-701-Q-GLB

$32.49 MSRP: $51.98You Save: $19.49 (38%)Ships in 1-2 Business DaysAudi A3 Connecting Rod Bearing Part Number: 06H-105-701-P-GLB

$36.89 MSRP: $50.82You Save: $13.93 (28%)Ships in 1-2 Business DaysAudi A3 Bearings Part Number: 06H-105-701-R-GLB

$36.89 MSRP: $50.82You Save: $13.93 (28%)Ships in 1-2 Business DaysAudi A3 Bearing Part Number: 06H-105-701-C-BLA

$10.56 MSRP: $16.50You Save: $5.94 (36%)Ships in 1-2 Business DaysAudi A3 Bearing Part Number: 06H-105-701-C-ROT

$10.56 MSRP: $16.50You Save: $5.94 (36%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

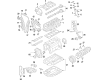

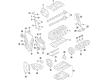

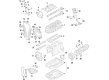

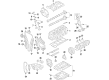

Audi A3 Rod Bearing

Choose original equipment manufacturer Rod Bearing for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Rod Bearing at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A3 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A3 needs now.

Audi A3 Rod Bearing Parts and Q&A

- Q: What essential considerations should be taken into account for rod bearing during engine overhaul on Audi A3?A:When the engine is undergoing an overhaul, the main and big-end bearings are to be replaced but saved to be examined because they may give a clue into the condition of the engine and common bearings failures. Failure due to improper lubricant, dirt or foreign particles, engine overloading, or corrosion possibilities can be borne and it is important to correct the cause of that situation before reassembling the engine to avoid its reoccurrence. In case they are found to bear shells, then they must be taken out of place and placed in a clean manner to enable easy matching to the crankshaft journal without touching on the internal surfaces to avoid scratches. Foreign matter may be introduced into the engine during assembling, by filters, or machining, usually becoming embedded in the bearing material giving rise to scoring or gouging. Cleaning up of every part and changing oil and filters regularly are important in prevention. Evidence of lack of lubrication may be attributed to excessive heat, overloading, leakage of oil or blocked passages that eventually cause serious damage such as overheating and extrusion of materials. Bearing life can also be affected by driving habits like full throttle low speed driving which result in fatigue failure. Driving that is short route also causes corrosion because of lack of enough heat to evaporate the moisture and gases and this leads to the formation of acids that corrode the bearing material. Improper installation may result in oil starvation and malfunctioning caused by close clearances or caught debris. Reassembling should be done safely so that the surface of the bearings is not contaminated internally. Main and big-end bearings come in standard and undersize models to support reground crankshafts and it is important to ensure that running clearances are met when using new bearings.