×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi 100 Control Arm

Suspension Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Control Arms found

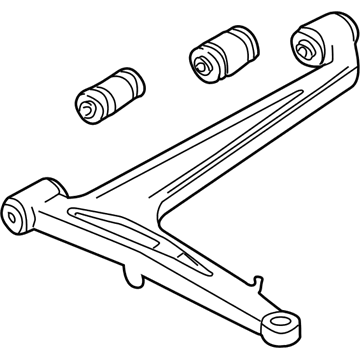

Audi 100 Lower Control Arm Part Number: 4A0-407-151

$174.50 MSRP: $244.40You Save: $69.90 (29%)Ships in 1-2 Business DaysAudi 100 Lower Control Arm Part Number: 4A0-407-152

$174.50 MSRP: $244.40You Save: $69.90 (29%)Ships in 1-2 Business DaysAudi 100 Lower Control Arm Part Number: 441-407-152-A

$386.99 MSRP: $542.00You Save: $155.01 (29%)Ships in 1-2 Business DaysAudi 100 Control Arm Part Number: 437-407-151-A

$351.01 MSRP: $491.62You Save: $140.61 (29%)Ships in 1-2 Business DaysAudi 100 Control Arm Part Number: 437-407-152-A

$357.71 MSRP: $501.00You Save: $143.29 (29%)Ships in 1-2 Business Days

Audi 100 Control Arm

Choose original equipment manufacturer Control Arm for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Control Arm at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi 100 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your 100 needs now.

Audi 100 Control Arm Parts and Q&A

- Q: What are the steps required for refitting the lower Control Arm and subframe mounting components on Audi 100?A:New control arm/subframe mounting bolt and washer, control arm balljoint clamp bolt and nut will be needed on refitting, and new anti-roll bar-to-control arm nut and anti-roll bar mounting clamp bolt nut. An extractor can be required to be in place to remove the control arm locating sleeve of the subframe that needs to clamp firmly to the internal sleeve that is approximately 12 mm in diameter so that it is easy to remove. Start with the removal of the anti-roll bar, chocking of the rear wheels, the use of the handbrake, lifting the front of the vehicle with a jack, and the use of the axle stands. Take out the suitable front road wheel; at least one wheel bolt should be fitted again, so as to maintain the position of the brake discs. Unscrew the nut and remove the bottom end control arm joint clamp bolt (lower) of the strut and dispose of the old clamp bolt and nut. Unscrew and take off the bolt and washer that attaches the inner end of the control arm to the subframe and dispose of them, and remove the locating sleeve in the inner bush of the control arm. In cases where the locating sleeve cannot be removed easily, the entire subframe assembly might have to be removed in order to tap the sleeve at the top. Aiming to take the control arm balljoint out of the strut base, loosen the arm out of the subframe, and pull it out of the automobile. Wash the control arm and its environs using a lot of water, scrutinize it, observing cracks, distortion, or wear, particularly on the inner pivot bush and balljoint, which cannot be replaced independently. When broken, the entire assembly has to be done away with. The inner pivot bush should be renewed with a hydraulic press and is most likely to be done by a garage or dealer who has the required equipment. Should one be available, press out the old bush and in place of it the new one using a spacer bearing on the outer bush edge only and positioning correctly. To refit, a control arm is to be brought into position working on the subframe, by engaging it, and so that the balljoint shank be placed in the bottom of the strut. Clamp the inner bush of the control arm to the subframe hole, fit the locating sleeve and tap until it clips into the subframe. Install the new washer, getting the tab in the slot on the subframe and screwing the new bolt into place, lightly. Install balljoint clamp bolt of the control arm in the back of the strut then install the new nut in order to tighten it to the required torque. Tighten inner bolt of subframe/control arm, to the given stage 1 torque, tighten with an angle-measuring gauge to the given stage 2 angle. Without a gauge, to check alignment between the bolt head and subframe, white paint is applied and then the tightening is done. Install the roadwheel again, drop the vehicle, and screw the wheel bolts to the tightening point. Lastly, replace the anti-roll bar and check the alignment of the front wheel, and correct if improper.