×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi A3 Valve Lifter

Lash Adjuster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Valve Lifters found

Audi A3 Valve Lifters Part Number: 03L-109-521-A

$6.60 MSRP: $10.31You Save: $3.71 (36%)Ships in 1-2 Business DaysAudi A3 Valve Lifters Part Number: 022-109-423-D

$13.49 MSRP: $21.57You Save: $8.08 (38%)Ships in 1-2 Business Days

Audi A3 Valve Lifter

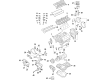

Choose original equipment manufacturer Valve Lifter for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Valve Lifter at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A3 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A3 needs now.

Audi A3 Valve Lifter Parts and Q&A

- Q: How to check and maintain the valve lifter if it becomes excessively noisy on Audi A3?A:The valve lifters are self-adjusting and require no attention while in service; however, if they become excessively noisy, their operation can be checked. To do this, run the engine until it reaches its normal operating temperature, then switch off the engine and remove the camshaft cover. Rotate the camshaft by turning the crankshaft with a socket and wrench until the first cam lobe over No 1 cylinder is pointing upwards. Using a non-metallic tool, press the lifter downwards and then use a feeler blade to check the free travel. If this is more than 0.2 mm before the valve starts to open, the lifter should be renewed. If valve lifter noise occurs repeatedly when traveling short distances, renew the oil retention valve located in the rear of the oil filter mounting housing. It will be necessary to remove the oil filter, unbolt the housing from the cylinder block, and recover the gasket. Use a suitable key to unscrew the valve and tighten the new valve securely before refitting the housing with a new gasket.

- Q: What are the steps required for refitting camshaft oil seals and removing the camshaft and valve lifter on Audi A3?A:Refitting will need new camshaft oil seals(s). In the case of DOHC engines, a VAG removal tool T10262 or similar tool will be required to loosen the retaining frame of the camshaft in order to avoid distortion and damage. Start by rotating the crankshaft to make No 1 piston arrive at TDC on the firing stroke, making sure that the camshaft and fuel injection sprocket are in place, and disassembling the Timing Belt, the sprocket on the camshaft, and the hubs. In the case of SOHC engines, the camshaft bearing caps should have identification marks on them, with the bearing caps being identified by number (1 through 5) and appropriate marks made in case none exist. Take the halves of the shells in the camshaft, and mark them, so that you can reassemble them, and loosen the nuts holding the bearing caps in place. Gradually loosen the nuts on Nos 2 and 4 bearing caps, dismount the caps, and take the camshaft off taking care not to tip it. Raise the hydraulic tappets out of the bores, and store them with the contact surfaces of the valves downwards, and regain the lower shell bearing halves. In case of DOHC engines, loosen the upper bolt connecting the EGA cooler bracket, disconnect wiring between unit injectors and glow plugs and loosen to the next step the bolts connecting the retaining frame to the camshaft. Check the VAG tool to take out the retaining bearing frame and carefully remove the camshafts out of the cylinder head, and dispose of the oil seals. To strip the exhaust roller rocker fingers and hydraulic tappets, empty the coolant and drain, strip the connecting pipe, and unscrew the plug of the end of the exhaust roller rocker shaft. A VAG slide hammer/puller tool is used to remove the shaft of the cylinder head by pulling it out while removing the roller rockers, which ought to be stored in numbered compartments on a container. Check the bearing caps/frame and bearing positions against wear, visually check the camshaft against wear on lobes and journals and measure the camshaft run-out and end float. Check the camshaft bearing running clearance and check the hydraulic tappets on wear. To refit, coat hydraulic tappets with engine slick, and lubricate the lobes of the camshaft. A camshaft may then be very carefully fitted in place, a new cam-shaft oil seal is re-fitted, and bearing caps tightened gradually. In the case of DOHC engines, apply some oil to roller rocker fingers and hydraulic tappets, fit each shaft in the cylinder head, and repeat the instructions. Apply grease to the camshaft and cylinder head bearing journals, place the camshafts into the cylinder, install new camshaft oil seals, and place sealant on the bearing frame and cylinder head mating surfaces. Install bearing frame, rocker arms, gradually tightening the retaining bolts and attaching the pump injector rocker arm shaft bolts. Last but not the least, replace the camshaft oil seal(s) where necessary, reattach the tandem fuel/brake vacuum pump, camshaft sprocket(s), hubs, and timing belt.