×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi 4000 Distributor

Ignition Distributor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Distributors found

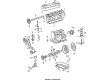

Audi 4000 Distributor Assembly Part Number: 034-905-205-F

$506.94 MSRP: $710.00You Save: $203.06 (29%)Ships in 1-2 Business DaysAudi 4000 Distributor Assembly Part Number: 050-905-237-CX

$122.43 MSRP: $170.00You Save: $47.57 (28%)Ships in 1-2 Business Days

Audi 4000 Distributor

Choose original equipment manufacturer Distributor for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Distributor at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi 4000 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your 4000 needs now.

Audi 4000 Distributor Parts and Q&A

- Q: How should you check and maintain the distributor before commencing work on Audi 4000?A:Check the availability of spare parts of a distributor separately before starting work. Contact breaker type: Wipe the distributor outside, remove the rotor arm off the cam spindler, and remove the dust cover underneath. Disassemble the contact breaker lead at the terminal on the side of the distributor, remove the clamp screw and washer on the contact breaker and lift the breaker assembly off the baseplate. Take the condenser out on the side of distributor and loosen the small spring clip attaching operating rod on vacuum unit to pin on contact breaker baseplate. Unscrew the screw that holds the vacuum unit in place to the distributor case and remove the vacuum unit since it will need no additional dismantling. Examine the inside of the distributor cap externally to see whether or not it is burning or tracking, the little carbon brush must be freely movable. Inspect the rotor arm and test the resistance between the brass contacts which should be 4000-6000 ohms. Check the movement of the operating rod by sucking on the connection of the pipe to the vacuum diaphragm and make sure that the diaphragm is not punctured. Reassembling it is also advisable to eliminate the old contact breaker and condenser and install new ones. Before reassembling, clean all components, do not put oil, grease, or dirt on the contacts and put grease on the cam sparingly. Install the vacuum unit and apply one drop of oil on top of the contact between the operating rod and the pin on the contact breaker plate and lubricate the felt at the cam recess with engine oil. Lastly, adjust and fit the contact breaker points. With transistorised ignition type, wipe clean external part of the distributor and remove rotor arm off the driveshaft and lift off dust cap without letting the clips fitting in the cap contact trigger wheel. Indicate the trigger wheel relative to the driveshaft, remove the retainer and pull out the wheel with the locating pin. Take out the retainer and washers, keeping a note of their position and then take out the vacuum unit and packing once the operating arm has been disconnected. Take the retainer out, the washer out of the baseplate, the screw which holds the socket to the side of the distributor, and bring out the baseplate, and then the washer. Wipe everything in the parts and inspect them to check the wear and damage, but the distributor cap, rotor arm, and vacuum unit, and remember that the rotor arm resistance level is 1000 ohms. In the same order in which the distributor was disassembled, assemble again, with a little grease on the bearing surface of the baseplate.

- Q: How to remove and refit the distributor in an ignition system on Audi 4000?A:Pull the high tension connection from the center of the Ignition Coil and remove the caps from the spark plugs. Release the two spring clips securing the distributor cap, then remove the cap with the ignition harness attached. For models with metal screening around the top of the distributor, remove the screw from the bonding strap before taking off the cap. Disconnect the low tension lead or the control unit lead multi-plug, as applicable. Note the exact position of the rotor arm to ensure the distributor can be fitted in the same position, and mark the distributor mounting flange and base to maintain ignition timing. Pull the vacuum pipe(s) from the vacuum control unit, marking their positions if there is more than one. Remove the bolt and washer from the distributor clamp plate, take off the clamp plate, and then remove the distributor and gasket. When refitting the distributor, always renew the gasket. Provided the crankshaft has not been moved, turn the rotor arm to a position that allows it to mesh correctly when the distributor is fully installed. If the distributor does not seat fully on a four-cylinder engine, withdraw the unit and use pliers to turn the oil pump driveshaft slightly before trying again. Fit the clamp plate and washer, then tighten the bolt. Finally, fit the distributor cap, clip it in place, and reconnect the high and low tension wires. If the engine has been overhauled, the crankshaft has been rotated, or a new distributor is being fitted, the installation procedure will vary according to engine capacity.