×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

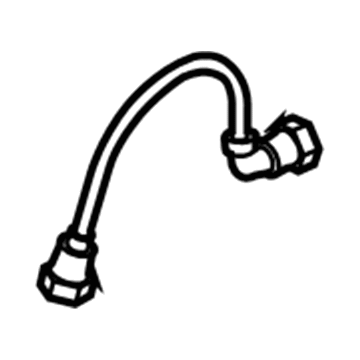

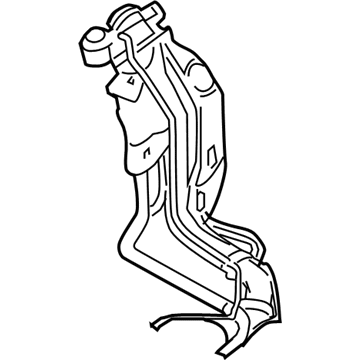

Genuine Audi Fuel Hose

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

43 Fuel Hoses found

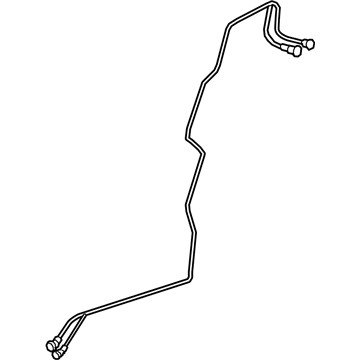

Audi Vent Tube Part Number: 5N0-201-993-S

$37.36 MSRP: $59.78You Save: $22.42 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Breather

- Replaces: 5N0-201-993-N

Audi Breather Tube Part Number: 8N0-201-993-C

$61.88 MSRP: $86.67You Save: $24.79 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube

Audi Breather Tube Part Number: 8N0-201-931-J

$70.21 MSRP: $98.33You Save: $28.12 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube

Audi Connector Hose Part Number: 420-201-143-C

$84.95 MSRP: $118.99You Save: $34.04 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose

Audi Connector Hose Part Number: 8E0-201-143-B

$94.00 MSRP: $131.65You Save: $37.65 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose

- Replaces: 8E0-201-143

Audi Breather Tube Part Number: 5QF-201-160-M

$69.01 MSRP: $96.65You Save: $27.64 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Breather; Breather Tube

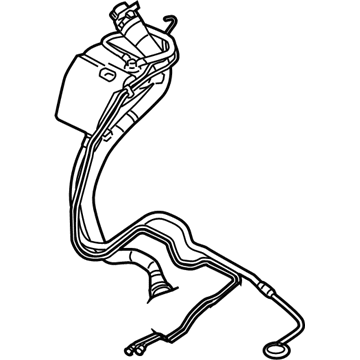

Audi Breather Tube Part Number: 7L8-201-851

$99.47 MSRP: $139.32You Save: $39.85 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube

Audi Vent Tube Part Number: 420-201-163-B

$92.81 MSRP: $129.98You Save: $37.17 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube

Audi Vent Tube Part Number: 427-201-163-A

$92.81 MSRP: $129.98You Save: $37.17 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube

Audi Breather Tube Part Number: 4E0-201-163-B

$103.52 MSRP: $144.98You Save: $41.46 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube

Audi Breather Tube Part Number: 8E0-201-183-AH

$107.10 MSRP: $150.00You Save: $42.90 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube

Audi Breather Tube Part Number: 8S0-201-931-E

$118.99 MSRP: $166.65You Save: $47.66 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Breather; Breather Tube

Audi Vent Tube Part Number: 4H0-201-167-M

$204.67 MSRP: $286.64You Save: $81.97 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube

Audi Breather Tube Part Number: 8S0-201-931-B

$124.94 MSRP: $174.98You Save: $50.04 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Breather

Audi Breather Tube Part Number: 4N0-201-183-A

$126.13 MSRP: $176.64You Save: $50.51 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Breather; Breather Tube

Audi Hose Part Number: 8J0-201-218-C

$139.22 MSRP: $194.99You Save: $55.77 (29%)Ships in 1-2 Business DaysAudi Breather Tube Part Number: 8N0-201-995-C

$122.57 MSRP: $171.67You Save: $49.10 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Breather

- Replaces: 8N0-201-995-A

Audi Breather Tube Part Number: 8E0-201-167-AP

$126.14 MSRP: $176.66You Save: $50.52 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube

Audi Hose Part Number: 4F0-201-218-E

$156.00 MSRP: $218.48You Save: $62.48 (29%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 8E0-201-218-Q

Audi Breather Tube Part Number: 8N0-201-995-B

$129.71 MSRP: $181.67You Save: $51.96 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Breather

- Replaces: 8N0-201-995

| Page 1 of 3 |Next >

1-20 of 43 Results

Audi Fuel Hose

The Audi Fuel Hose is a very important part of your vehicle. Therefore, it has to be maintained in good condition to avoid performance issues and comfortable driving. And these regular checks and replacements will ultimately save you some big repair costs. It is better to choose OEM parts when it comes to the time for fixing them. Why? Because they fit perfectly well and ensure safety. For people who prefer doing their maintenance, the genuine Audi Fuel Hose is quite perfect. At AudiPartsGiant.com, we specialize in genuine Audi Fuel Hoses only. Also, we offer an extensive online catalog with many categories, ample stock, and secure shopping. The Audi Fuel Hose is shipped directly from authorized Audi dealers at competitive prices. So trust us, and we will give you nothing but superior service. Depend on us for all your genuine parts needs, and then we will keep your automobile moving smoothly.

Audi Fuel Hose Parts and Q&A

- Q: What are the essential steps and precautions for replacing fuel hoses and inspecting related components on Audi A4?A:Replacement of air conditioning hoses are to be only postponed to a dealer service department or air conditioning shop capable of safely depressurizing the system and extracting refrigerant. Always take care not to take out air conditioning parts or hoses before depressurizing. An engine compartment may experience high temperatures that lead to the degradation of rubber and plastic hoses that are used to operate the engine, accessory, and emission systems and hence inspection to check against cracks, loose clamps, hardening of material and leaks is necessary on a regular basis. Other hoses are clamped and they need to be tensioned to avoid leakages and those that are not clamped need to be monitored on whether they have expanded or hardened. Color-coded or striped: The use of vacuum hoses especially in the emissions system, the replacement hose must be of the same material. Checking a hose can best be done by taking the hose all the way off, marking hoses and fittings so they can be installed properly. Check any plastic T-fittings during the inspection, both in terms of cracks and distortion that may be the cause of leakage. Vacuum leaks may be detected by simply listening to hissing by using a small hose of vacuum. The rubber fuel lines must be inspected on their detergence and chafing, and particularly holes that are made when the hose is bent or connected to fittings. Replacements of fuel lines to high pressure fuel injection systems should be with high-quality fuel line that is not unreinforced vacuum lines or clear plastic tubing. Clamps on fuel lines are spring-type that tend to lose their tension as time goes by and need to be replaced with screw clamps when changing hoses. Areas of metal line that were routed along the frame between the fuel tank and engine should be inspected to ensure that they do not contain bends, crimps or cracks. When replacing a metal fuel line, seamless steel tubing should be employed, and copper and aluminum do not have the required strength to survive the vibration of the engine. Also, inspect metal brake lines at the master cylinder and brake proportioning unit of cracks or loose fittings of which any indication of brake fluid leakage should be an immediate and exhaustive inspection of the brake system.

Related Audi Parts

Browse by Model

100 Fuel Hose 100 Quattro Fuel Hose A3 Sportback e-tron Fuel Hose A4 Fuel Hose A4 Quattro Fuel Hose A5 Fuel Hose A5 Quattro Fuel Hose A6 Fuel Hose A6 Quattro Fuel Hose A8 Quattro Fuel Hose Cabriolet Fuel Hose Q3 Fuel Hose Q3 Quattro Fuel Hose Q5 Fuel Hose Q5 PHEV Fuel Hose Q7 Fuel Hose R8 Fuel Hose RS4 Fuel Hose RS5 Fuel Hose S4 Fuel Hose S5 Fuel Hose S6 Fuel Hose S8 Fuel Hose TT Fuel Hose TT Quattro Fuel Hose TT RS Quattro Fuel Hose TTS Quattro Fuel Hose V8 Quattro Fuel Hose allroad Fuel Hose