×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

106 Exhaust Manifolds found

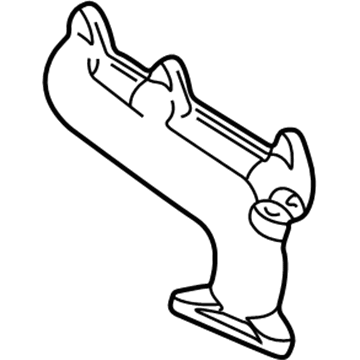

Audi Exhaust Manifold Part Number: 078-253-031-BA

$166.97 MSRP: $233.85You Save: $66.88 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Left

- Replaces: 078-253-031-AS

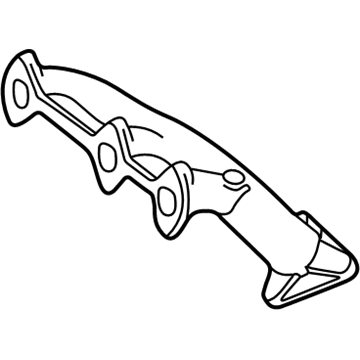

Audi Exhaust Manifold Part Number: 078-253-032-BA

$166.97 MSRP: $233.85You Save: $66.88 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Right

- Replaces: 078-253-032-AS

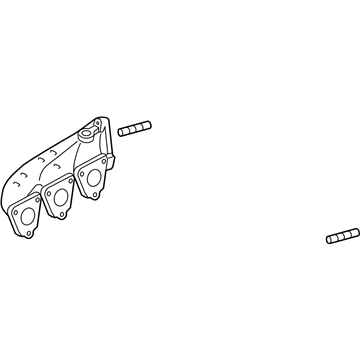

Audi Exhaust Manifold Part Number: 06E-253-032-AC

$359.38 MSRP: $503.34You Save: $143.96 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Right

Audi Exhaust Manifold Part Number: 078-253-031-AN

$244.90 MSRP: $343.00You Save: $98.10 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold; Exhaust Manifold

- Position: Left

Audi Exhaust Manifold Part Number: 078-253-032-AP

$244.90 MSRP: $343.00You Save: $98.10 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold; Exhaust Manifold

- Position: Right

Audi Exhaust Manifold Part Number: 022-253-033-M

$268.94 MSRP: $376.67You Save: $107.73 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Replaces: 022-253-033-E

Audi Exhaust Manifold Part Number: 03H-253-031-C

$82.54 MSRP: $115.60You Save: $33.06 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Replaces: 03H-253-031-B

Audi Exhaust Manifold Part Number: 03H-253-032-C

$275.14 MSRP: $385.35You Save: $110.21 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Replaces: 03H-253-032-B

Audi Exhaust Manifold Part Number: 06E-253-031-AC

$359.38 MSRP: $503.34You Save: $143.96 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Left

- Replaces: 06E-253-031-P, 06E-253-031-M

Audi Exhaust Manifold Part Number: 059-253-034-BP

$752.66 MSRP: $973.07You Save: $220.41 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Right

- Replaces: 059-253-034-AQ

Audi Exhaust Manifold Part Number: 059-253-033-AC

$340.59 MSRP: $477.03You Save: $136.44 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Left

- Replaces: 059-253-033-S

Audi Exhaust Manifold Part Number: 059-253-034-AC

$369.25 MSRP: $517.15You Save: $147.90 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Right

- Replaces: 059-253-034-S

Audi Exhaust Manifold Part Number: 06E-253-031-AB

$413.81 MSRP: $579.57You Save: $165.76 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Left

- Replaces: 06E-253-031-N, 06E-253-031-J, 06E-253-031-Q, 06E-253-031-F

Audi Manifold Part Number: 078-253-031-AF

$342.72 MSRP: $480.00You Save: $137.28 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Audi Manifold Part Number: 078-253-032-AF

$342.72 MSRP: $480.00You Save: $137.28 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Audi Exhaust Manifold Part Number: 079-253-034-AQ

$458.38 MSRP: $641.97You Save: $183.59 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Right

Audi Exhaust Manifold Part Number: 022-253-017-M

$367.71 MSRP: $515.00You Save: $147.29 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

Audi Exhaust Manifold Part Number: 022-253-018-P

$367.71 MSRP: $515.00You Save: $147.29 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

Audi Exhaust Manifold Part Number: 06E-253-032-AB

$429.72 MSRP: $601.85You Save: $172.13 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Right

- Replaces: 06E-253-032-J, 06E-253-032-F, 06E-253-032-Q, 06E-253-032-N

Audi Exhaust Manifold Part Number: 06E-253-032-K

$410.54 MSRP: $574.99You Save: $164.45 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold

- Position: Right

- Replaces: 06E-253-032-D, 06E-253-032-H

| Page 1 of 6 |Next >

1-20 of 106 Results

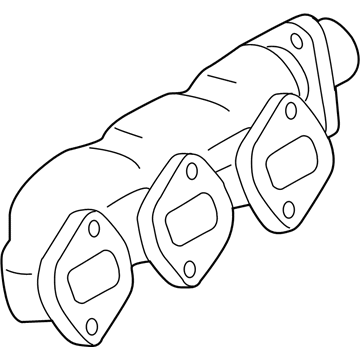

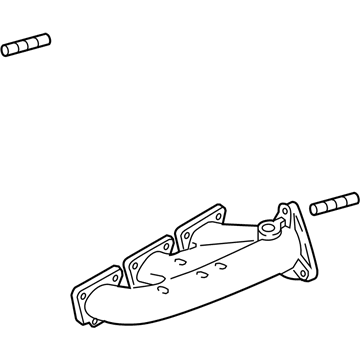

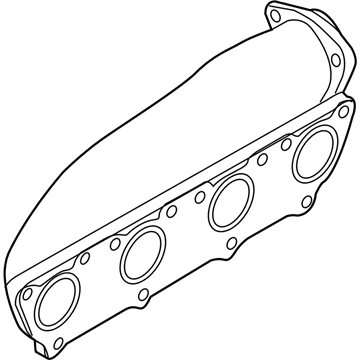

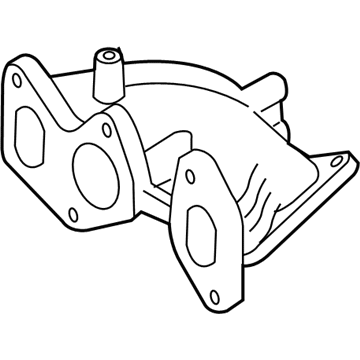

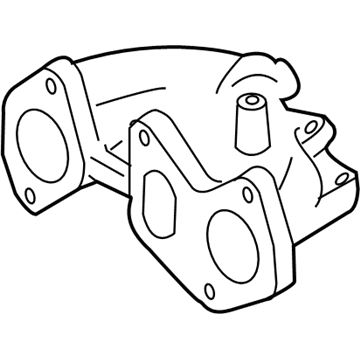

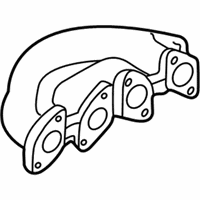

Audi Exhaust Manifold

Exhaust gases from each cylinder are emitted into the exhaust manifold when the engine is on. Typically, simple cast iron or stainless steel units make up an exhaust manifold. The following are some indications that your Audi exhaust manifold is worn out: noisy engine while driving, ineffective engine, Check Engine Light (CEL) on, and strange smell from the bonnet towards the passenger compartment. For safety, you need to have waste gases directed through proper channels. Otherwise, excessive heat could lead to fire accidents. You should regularly inspect your exhaust manifold and replace it promptly if it is not working well.

It is better to choose OEM parts when it comes to the time for fixing them. Why? Because they fit perfectly well and ensure safety. For people who prefer doing their maintenance, the genuine Audi Exhaust Manifold is quite perfect. At AudiPartsGiant.com, we specialize in genuine Audi Exhaust Manifolds only. Also, we offer an extensive online catalog with many categories, ample stock, and secure shopping. The Audi Exhaust Manifold is shipped directly from authorized Audi dealers at competitive prices. So trust us, and we will give you nothing but superior service. Depend on us for all your genuine parts needs, and then we will keep your automobile moving smoothly.

Audi Exhaust Manifold Parts and Q&A

- Q: How to remove and refit the exhaust manifold on Audi 100?A:In the case of petrol engines, it is best to start by using handbrake, lifting the front part of the car on axle stands, and placing it on axle stands. Take the undershield out of the engine compartment, then unscrew the nuts to disassemble the exhaust downpipe off of the exhaust manifold, be it on an axle stand and retrieve the gasket. The next step is to unscrew the nuts and take off the hot air shroud off the exhaust manifold, and unscrew and remove the oxygen sensor, where necessary. In ACE and AAA engines, un screw the union nut, and unbolt the CO extractor pipe to the exhaust manifold. Gradually loosen the mounting nuts, take out the washers and take the exhaust manifold out of the cylinder head, reclaiming the gaskets and recording the position of the inlet manifold supporting brackets. On the AAA engine, divide the two parts of the exhaust manifold in a manner by unscrewing the clamp bolts, then removing the clamps, connecting the pipe, and the corrugated pipe. Wipe the mating surfaces of the manifold and cylinder head, find new gaskets on the studs, and on the AAA engine, clean the inner ends of the two portions, re-assemble them, and loosely screw the clamp bolts. Install the exhaust manifold, screw the mounting nuts to the set amount of torque, clamp the AAA engine mounting nuts to the full extent and install the CO extractor pipe, having screwed the union nut and mounting bolt. Install the oxygen sensor in place where needed, screw it in to the required torque, and reinstall the hot air shroud and exhaust downpipe, screw the nuts to the required tight before re-fitting the engine undershield and then lowering the car to the ground. In the case of diesel engines, especially when it is equipped with a turbocharger, the turbocharger and the exhaust manifold should be taken out to enhance easy access. Start with the application of a handbrake, lifting the front of the vehicle and placing it on stands that are supported on the axles. To separate the exhaust downpipe and turbocharger or exhaust manifold, cut off the undershield and unscrew the nuts which retain the downpipe to the axle stand and retrieve the gasket. Detach the vacuum hoses, air inlet hose, and the union nuts to the turbocharger, detach the oil supply and return pipes, unbolt and unscrew the oil return pipe at the crankcase and reclaim the gasket. Screw the mounting nuts out, one after the other, take out the washers, and take out the exhaust manifold of the cylinder head, and retrieve the gaskets. Should it be necessary, loosen the mounting nuts of the bench to take off the turbocharger and salvage the gaskets, then dispose of the nuts as new ones will have to be replaced. Wipe the mating surfaces of the manifold and cylinder head, find new gaskets on the studs, and reattach the turbocharger to the manifold with a new gasket, screwing the new mounting nuts to the required torque. Re-fit the manifold to the cylinder head, nutscrew to the recommended torque, and reconnect the oil supply and return pipes with new O-rings/gaskets, screwing the nuts and bolts to the recommended torque. Lastly, install a new gasket on the exhaust downpipe between the turbocharger or manifold and the exhaust, reattach the nuts to the correct torque, replace the undershield and drop the car to the ground.

- Q: How to remove and install the exhaust manifold for Four-cylinder engines on Audi A4?A:This procedure applies to the 1.8L engine only. For exhaust manifold removal and installation on 2.0L engines, consult the relevant materials. Begin by removing the engine cover, followed by the air intake duct and air cleaner housing. Raise the front of the vehicle and support it securely on jackstands, then remove the splash guard from below the engine compartment. Loosen the turbocharger support bracket bolts several turns, then detach the turbocharger oil supply line from the exhaust manifold heat shield if equipped. Remove the exhaust manifold heat shield, then take out the three bolts securing the turbocharger to the exhaust manifold and lower the turbocharger slightly. Remove the turbocharger to exhaust manifold gasket and cover the opening of the turbocharger with a rag to prevent dirt particles and foreign objects from entering. Detach the exhaust manifold and gasket, applying penetrating oil to the manifold mounting nuts or bolts if necessary to facilitate removal. For installation, use a scraper to remove all traces of old gasket material and carbon deposits from the manifold and cylinder head mating surfaces. If the gasket was leaking, have the manifold checked for warpage at an automotive machine shop and resurfaced if necessary. Position a new gasket over the cylinder head studs, install the manifold, and thread the mounting nuts or bolts into place, ensuring to use hi-temp anti-seize compound on the exhaust manifold fasteners. Tighten the nuts or bolts from the center out to the specified torque in three or four equal steps, then reinstall the remaining parts in the reverse order of removal. Finally, run the engine and check for exhaust leaks.

Related Audi Parts

Browse by Model

100 Exhaust Manifold 100 Quattro Exhaust Manifold 200 Exhaust Manifold 200 Quattro Exhaust Manifold 4000 Exhaust Manifold 4000 Quattro Exhaust Manifold 5000 Exhaust Manifold 5000 Quattro Exhaust Manifold 80 Exhaust Manifold 80 Quattro Exhaust Manifold 90 Exhaust Manifold 90 Quattro Exhaust Manifold A3 Quattro Exhaust Manifold A4 Exhaust Manifold A4 Quattro Exhaust Manifold A5 Quattro Exhaust Manifold A6 Exhaust Manifold A6 Quattro Exhaust Manifold A7 Quattro Exhaust Manifold A8 Exhaust Manifold A8 Quattro Exhaust Manifold Allroad Quattro Exhaust Manifold Cabriolet Exhaust Manifold Coupe Exhaust Manifold Coupe Quattro Exhaust Manifold Q5 Exhaust Manifold Q7 Exhaust Manifold Quattro Exhaust Manifold R8 Exhaust Manifold RS Q8 Exhaust Manifold RS4 Exhaust Manifold RS5 Exhaust Manifold RS6 Avant Exhaust Manifold RS7 Sportback Exhaust Manifold S4 Exhaust Manifold S5 Exhaust Manifold S6 Exhaust Manifold S8 Exhaust Manifold SQ5 Exhaust Manifold SQ7 Exhaust Manifold SQ8 Exhaust Manifold TT Exhaust Manifold TT Quattro Exhaust Manifold V8 Quattro Exhaust Manifold