×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi A3 Control Arm

Suspension Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Control Arms found

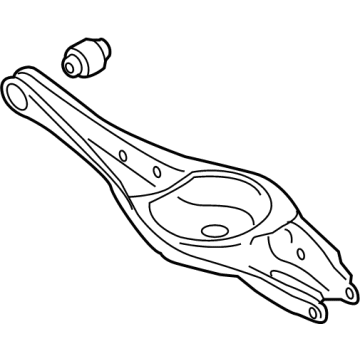

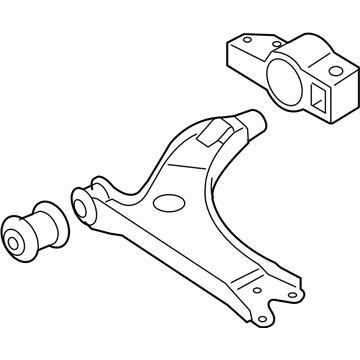

Audi A3 Lower Control Arm Part Number: 5WA-505-311-A

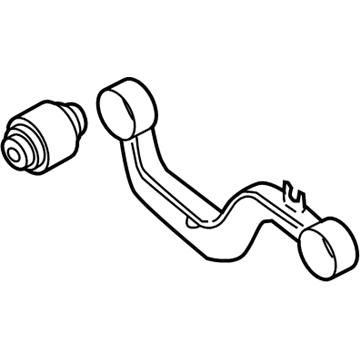

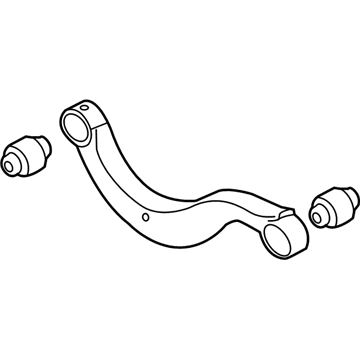

$118.69 MSRP: $166.24You Save: $47.55 (29%)Ships in 1-2 Business DaysAudi A3 Upper Control Arm Part Number: 1K0-505-323-N

$176.43 MSRP: $247.10You Save: $70.67 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 1K0-407-151-AD

$199.91 MSRP: $279.99You Save: $80.08 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 1K0-407-152-AD

$199.91 MSRP: $279.99You Save: $80.08 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 1K0-407-151-BC

$223.65 MSRP: $313.24You Save: $89.59 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 1K0-407-152-BC

$216.25 MSRP: $302.87You Save: $86.62 (29%)Ships in 1-2 Business DaysAudi A3 Upper Control Arm Part Number: 5Q0-505-323-D

$229.90 MSRP: $321.98You Save: $92.08 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 1K0-407-151-AC

$237.39 MSRP: $332.48You Save: $95.09 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 1K0-407-152-AC

$237.39 MSRP: $332.48You Save: $95.09 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 1K0-407-151-BD

$257.04 MSRP: $360.00You Save: $102.96 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 1K0-407-152-BD

$262.99 MSRP: $368.34You Save: $105.35 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 5WA-407-151

$268.63 MSRP: $376.23You Save: $107.60 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 5WA-407-152

$274.88 MSRP: $384.98You Save: $110.10 (29%)Ships in 1-2 Business DaysAudi A3 Lower Control Arm Part Number: 5Q0-505-311-J

$367.63 MSRP: $514.89You Save: $147.26 (29%)Ships in 1-2 Business Days

Audi A3 Control Arm

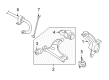

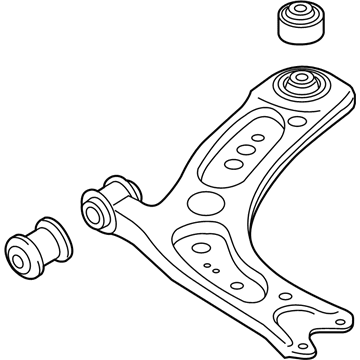

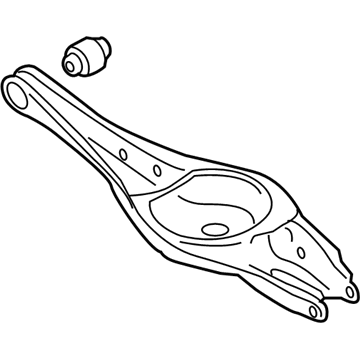

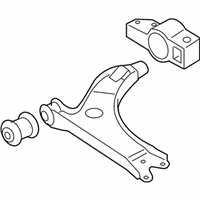

The Audi A3 Control Arm is the connection point between the front wheel setup and the chassis, allowing the front wheel to lift over bumps and maintain steering accuracy. In successive generations of Audi, this wishbone-fashioned part anchors shock absorbers, coil springs, and the sway bar within the normal Audi chassis, and its rubber bushings at the frame and ball joint at the knuckle permit controlled pivoting. The previous Audi compacts were based on a stamped steel Control Arm, which is strong but can easily be overloaded and, thus, in case of severe corrosion or hitting a curb, replacement is necessary, but later models shifted to cast iron or cast aluminum examples, which are heavier but stronger and more resistant to corrosion. Regardless of the material, all Control Arms pass the suspension load via their mount points, and in the common MacPherson strut front system applied by the A3 range they do so perpendicular to the car, with a separate radius rod to keep the front wheel from moving fore and aft. In case the bushings or the ball joint wear, they can normally be serviced separately, leaving the main Control Arm. Since the Control Arm connects critical suspension geometry, any bending or deformation instantly influences alignment and ride quality, which is why it is important for every Audi driver concerned with handling sharpness to check it periodically.

Choose original equipment manufacturer Control Arm for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Control Arm at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi A3 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your A3 needs now.

Audi A3 Control Arm Parts and Q&A

- Q: How should the front lower Control Arm be renewed and what steps are necessary to ensure proper installation and alignment on Audi A3?A:The control arm is available in either cast steel or sheet steel, so when renewing the arm, ensure the correct type is fitted according to the model. Audi subframe locating pins (T10096) or similar are necessary for the work to ensure correct front wheel alignment. All self-locking nuts and bolts disturbed during removal must be renewed. Begin by applying the handbrake, jacking up the front of the vehicle, and supporting it on axle stands before removing the appropriate front roadwheel and engine compartment undertray. Unscrew the front suspension lower balljoint-to-control arm retaining nuts, then lever down the control arm to release it from the balljoint studs. Audi technicians typically use locating pins T10096 in place of the rear outer subframe mounting bolts for alignment; if these pins are unavailable, only remove and refit one control arm at a time, marking the subframe's position with paint. Remove the rear outer mounting bolt, substituting it with a locating pin tightened to 20 Nm (15 lb. ft) if available, then unscrew and remove the front mounting bolt, supporting the control arm while unscrewing the two rear inner mounting bolts to remove the control arm from beneath the car. Clean the control arm thoroughly and check for cracks or signs of wear, especially in the rubber mounting bushes. If renewal is needed, take the control arm to an Audi dealer or a suitably-equipped garage, or use a hydraulic press with spacers to press out the old bushes and install new ones, dipping them in a mild solution of washing-up liquid and water. When fitting a new front mounting bush, tilt it initially with one lip in the bore, allowing it to straighten as it is inserted, ensuring it is centered. After pressing a new rear mounting bush into the rear mounting bracket, press the bracket and bush fully onto the control arm rear pivot. To refit, locate the control arm on the subframe and insert the front mounting bolt loosely, followed by the two rear outer mounting bolts, positioning the inner bolt hole as noted during removal. If an Audi location pin was used, the bracket will be correctly positioned. Tighten the two outer bolts to the specified torque, remove the pin, refit the inner bolt, and tighten it to the specified torque, followed by tightening the front mounting bolt. Finally, lever down the control arm to locate the balljoint studs in their holes, fit the new nuts, and tighten them to the specified torque before refitting the roadwheel and undertray, then lowering the car to the ground.

- Q: How to remove and refit the rear control arm on Audi A3?A:In order to take out the rear track control rod, chock the front roadwheels first, then jack up the rear of the car and place it on axle stands and then take out the corresponding rear roadwheel. Record the adjusted position of the rear track control rod with the closed side with the forwards side and the mounting bolts orientation. Unscrew the mounting bolts and nuts and pull out the track control rod, under the vehicle, being careful not to lose the special washer underneath the head of the bolt fitting the outer end of the rod to the wheel bearing housing. To re-fit, reverse the undoing operation, and tighten the bolts to the required torque and rearrange the rod and bolts as observed above. Make sure that there is clearance between the special 'star' washer and the track control rod and check the rear wheel alignment and adjust where necessary by an Audi dealer.