×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Audi Parts

My Garage

My Account

Cart

Genuine Audi 4000 Pressure Plate

Clutch Pressure Plate- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Pressure Plate found

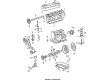

Audi 4000 Pressure Plate Part Number: 035-141-117-EX

$155.21 MSRP: $216.65You Save: $61.44 (29%)Ships in 1-2 Business Days

Audi 4000 Pressure Plate

Choose original equipment manufacturer Pressure Plate for great performance and strong durability. They use Audi's official craftsmanship and high-grade materials, and meet strict quality standards. Are you looking for quality Pressure Plate at a good price? Come to our online store. We carry a wide range of genuine parts for your Audi 4000 and the prices are competitive. Each part comes with the manufacturer's warranty. You can install with confidence and get steady results. Over time, you'll save money and avoid hassle. Keep your maintenance simple and protect your vehicle with OEM parts. Get the quality your 4000 needs now.

Audi 4000 Pressure Plate Parts and Q&A

- Q: How can access to the clutch disc, clutch release bearing, and pressure plate be achieved, and what steps should be followed for proper inspection and reassembly on Audi 4000?A:The clutch can be accessed by dismounting either the engine or the gearbox, the former being the choice process in case a serious repair may be needed on the engine and there is sufficient clearance. Label the rim of the cover of the clutch pressure plate and the flywheel to be properly reassembled. Relax the retaining bolts of the clutch cover in a form of diagonal pattern and then loosen the bolts and remove them and then lift the clutch cover and friction plate. Wipe all components using a moist cloth without breathing in dust which might have asbestos which is harmful. Check the wear and tear of the diaphragm spring; when the scoring is more than 0.3 mm, change the cover assembly. Inspect the clutch cover with straight edge, discarding it when any gaps more than 0.3 mm. and make sure that the pressure plate does not suffer any scoring, cracking, or burning, and the friction plate is replaced in case the material is worn or oily. Check the splined hub regarding damages and considering that it should move freely on the input shaft of the gearbox. In the event that the hub is suspected to be running true, a dial gauge check is made. Do not abuse any of the parts that a suspect, examine the flywheel and repaint or replace the damaged parts. Before reassembling, ensure everything is clean and in a good condition. Put the friction plate having torsion spring cages in front of the pressure plate and next put on the clutch cover aligning the marks already drawn and fasten the bolts loosely. Align the friction plate by means of a tool so that it fits properly with the crankshaft because otherwise, gearbox reinstallation will be complicated. Clamp the bolts of the clutch cover in a diagonal manner until the required torque is achieved and then wipe the centralizing tool off and apply the molybdenum disulphide grease to the hub splines. Last but not least, ensure the bearing of the release is in good condition and works smoothly and change it in case of need and refit the engine or gearbox.